Method for clamping a tool or a workpiece and device for performing the method

A technology for clamping tools and fixtures, applied in metal processing machine parts, manufacturing tools, metal processing, etc., can solve problems such as high inaccuracy, inaccurate simulated length measurement, etc., and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

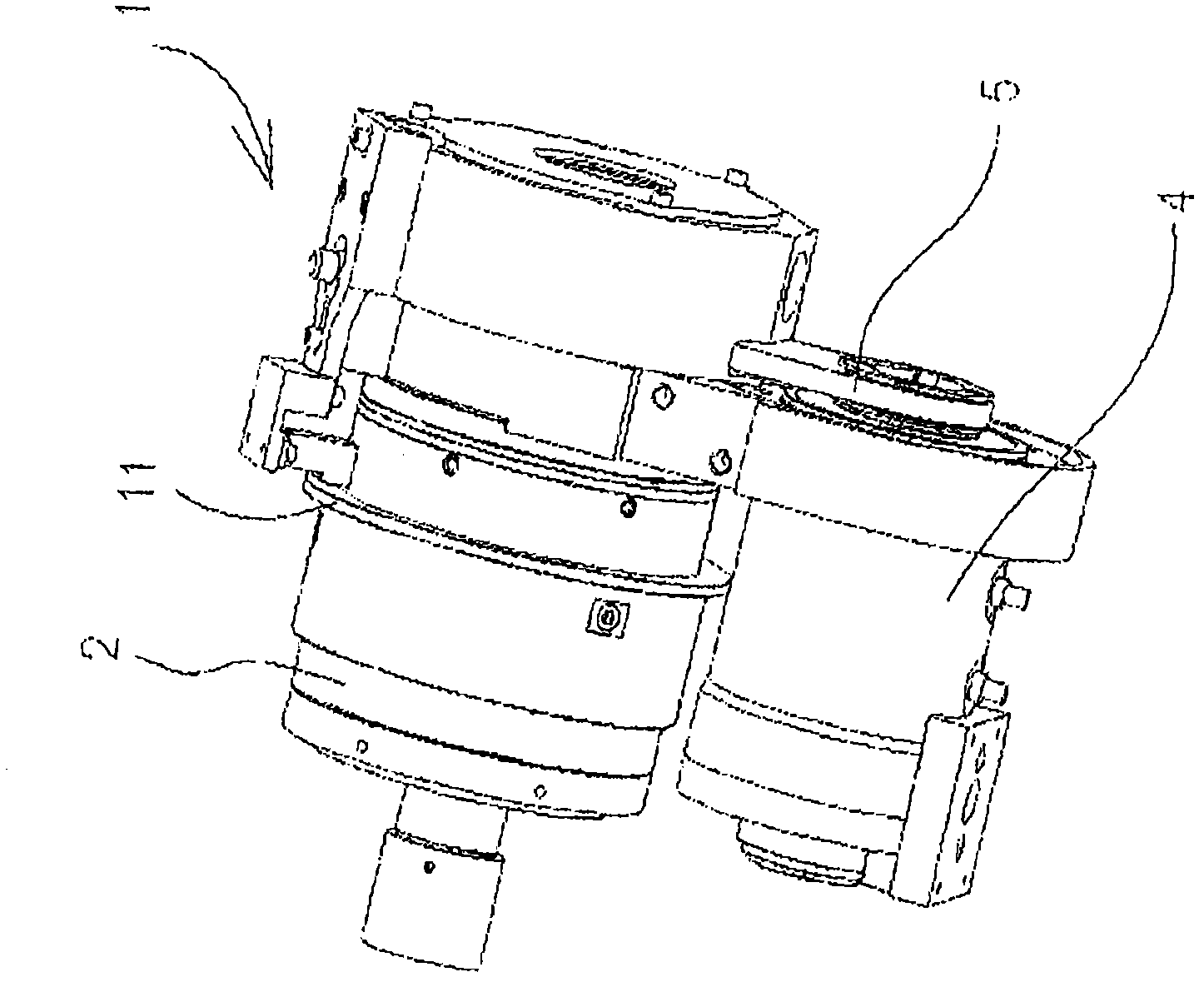

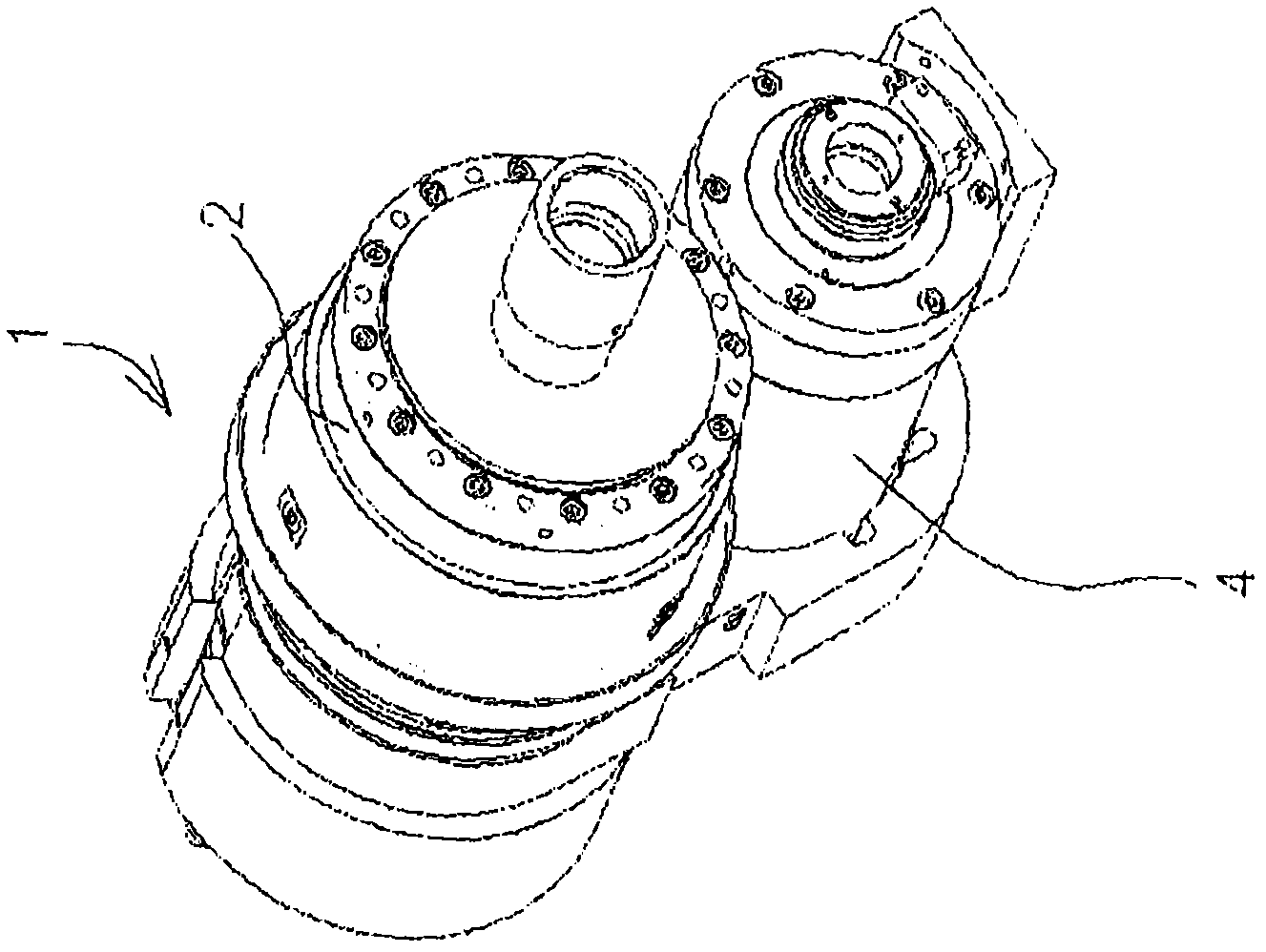

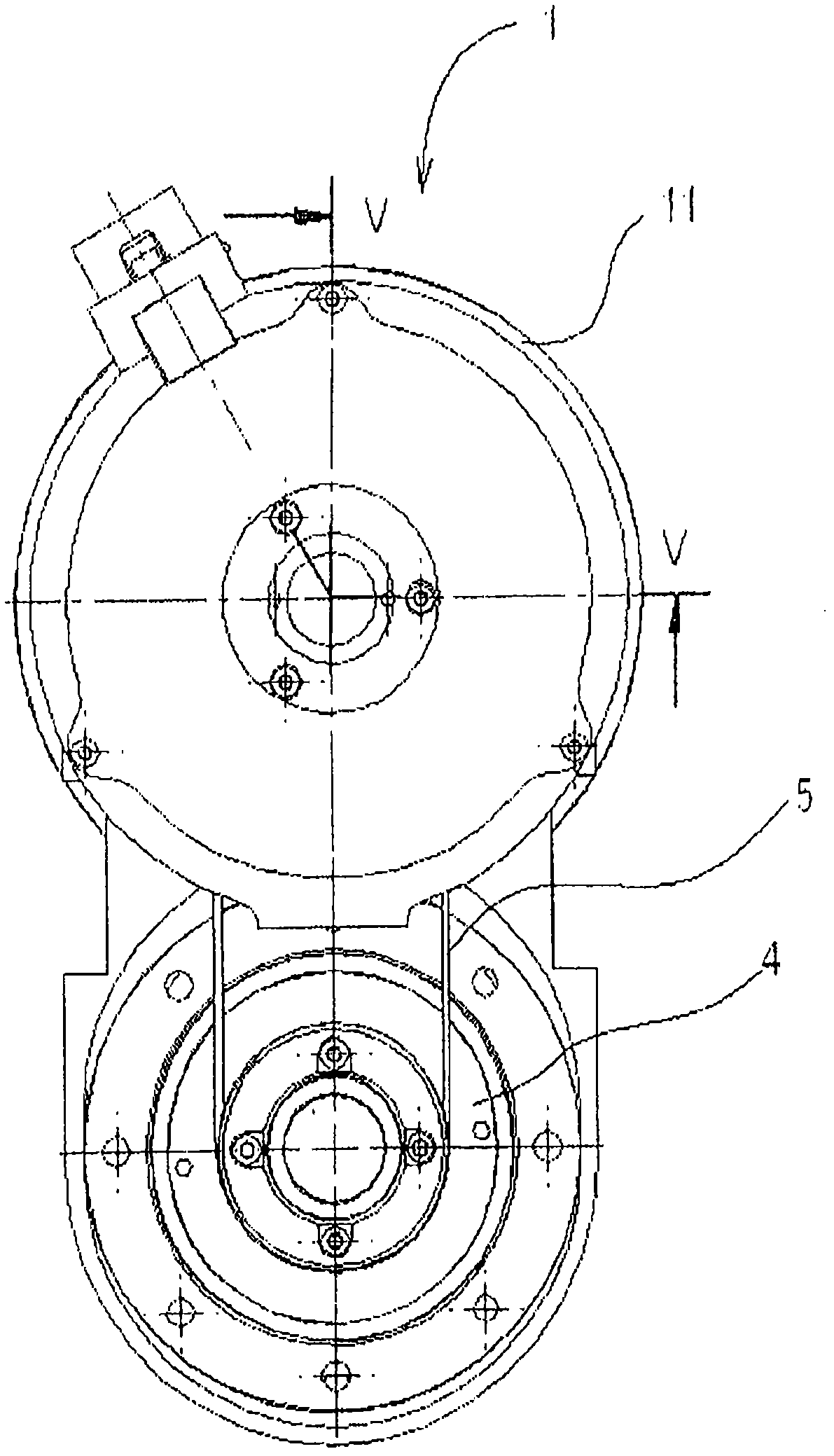

[0020] The drawing shows an electric clamping clamp 1 , which serves to adjust the jaws of a chuck fixed to a machine tool and clamps it continuously and securely relative to a workpiece or tool during the clamping process. The electric clamp 1 has a housing 2 to be fixed on the working spindle of the machine tool, in which a threaded rod 3 is axially adjustable for adjusting the jaws of the chuck. The electric gripper 1 also includes an electric servomotor 4 which is arranged laterally next to the housing 2 . As the transmission between the electric servo motor 4 and the screw 3, a harmonic drive is used, wherein the rotor of the servo motor 4 is connected to the drive wheel 6 through a belt drive 5, and the drive wheel is connected to the coaxial exciter of the harmonic drive. The hollow wheel of the harmonic drive is connected with the housing 2, and the flexible spine (Flex-Spine) of the harmonic drive acts as the drive of the screw 3. In the embodiment shown in the drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com