Suspension clamping vibration harvester

A technology for hanging clips and harvesters, which is applied in the directions of pickers, harvesters, agricultural machinery, and implements, can solve the problems of restricting the use and promotion of harvesting machinery, the impact of fruit collection, and low picking efficiency, and can meet the requirements of vibration and fall picking. Demand, ease of picking and collection, effect of increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Combine below Figure 1 to Figure 14 The embodiments of the present invention will be described in detail.

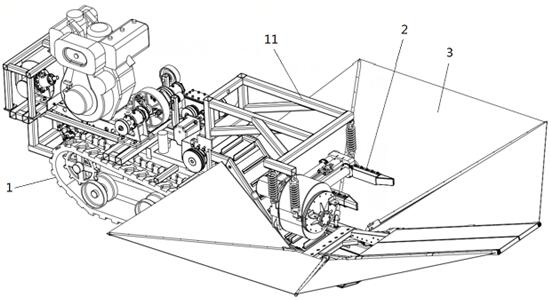

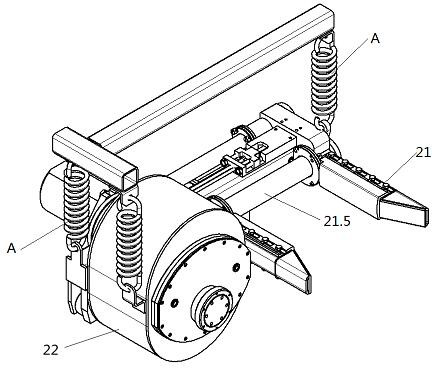

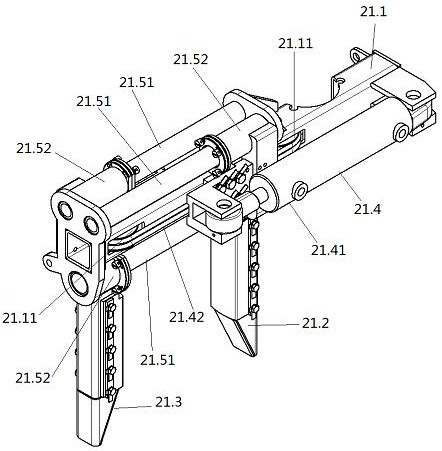

[0043] Suspended clamping vibrating harvester, including a crawler-type traveling mechanism 1, a fruit picking mechanism 2 installed on the crawler-type traveling mechanism 1 for vibrating and picking fruits, and a fruit collecting mechanism 3 installed at the front end of the crawler-type traveling mechanism 1 for collecting fruits , it is characterized in that: the fruit picking mechanism 2 is suspended on the frame 11 protruding forward of the crawler-type traveling mechanism 1 through a plurality of vertically arranged springs A and is located directly above the fruit collecting mechanism 3, the fruit picking mechanism 2 It includes a clamping assembly 21 for clamping the tree trunk and a vibrator 22 mounted on the clamping assembly 21. The clamping assembly 21 includes a horizontally arranged clamping bracket 21.1, an inner clamping plate 21.2 protruding for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com