[0012] However, in the above-mentioned prior art live fish

water cooling device, the relatively long

refrigerant piping is arranged in a zigzag manner across the bottom surface or side wall surface of the live fish tank or inside the wet filter tank, and the

evaporator is arranged on the The live fish water tank or the wet filter itself, so there is a problem that it takes a lot of time and money to install the live fish

water cooling device, and it also takes a lot of time and money to repair or maintain the live fish

water cooling device.

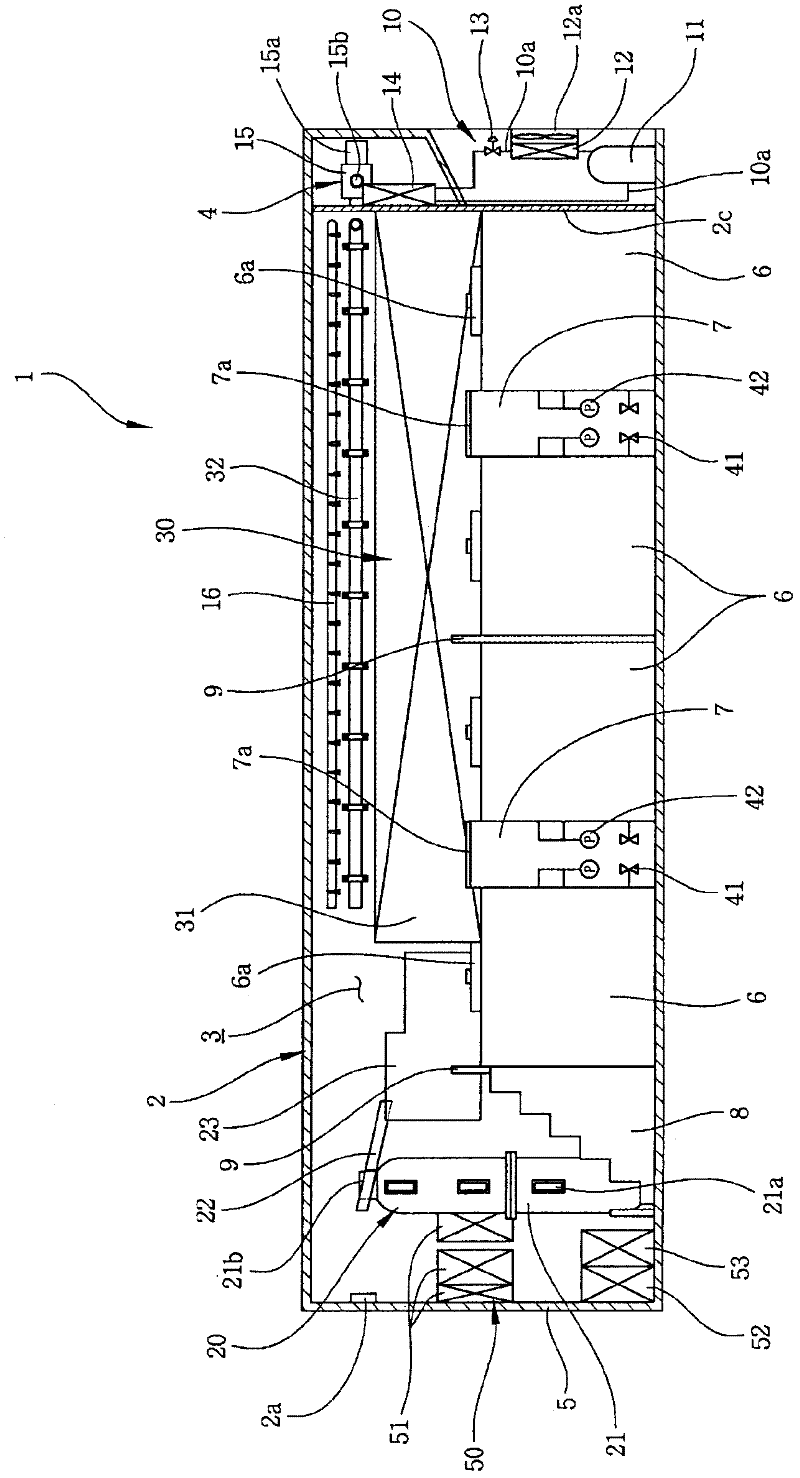

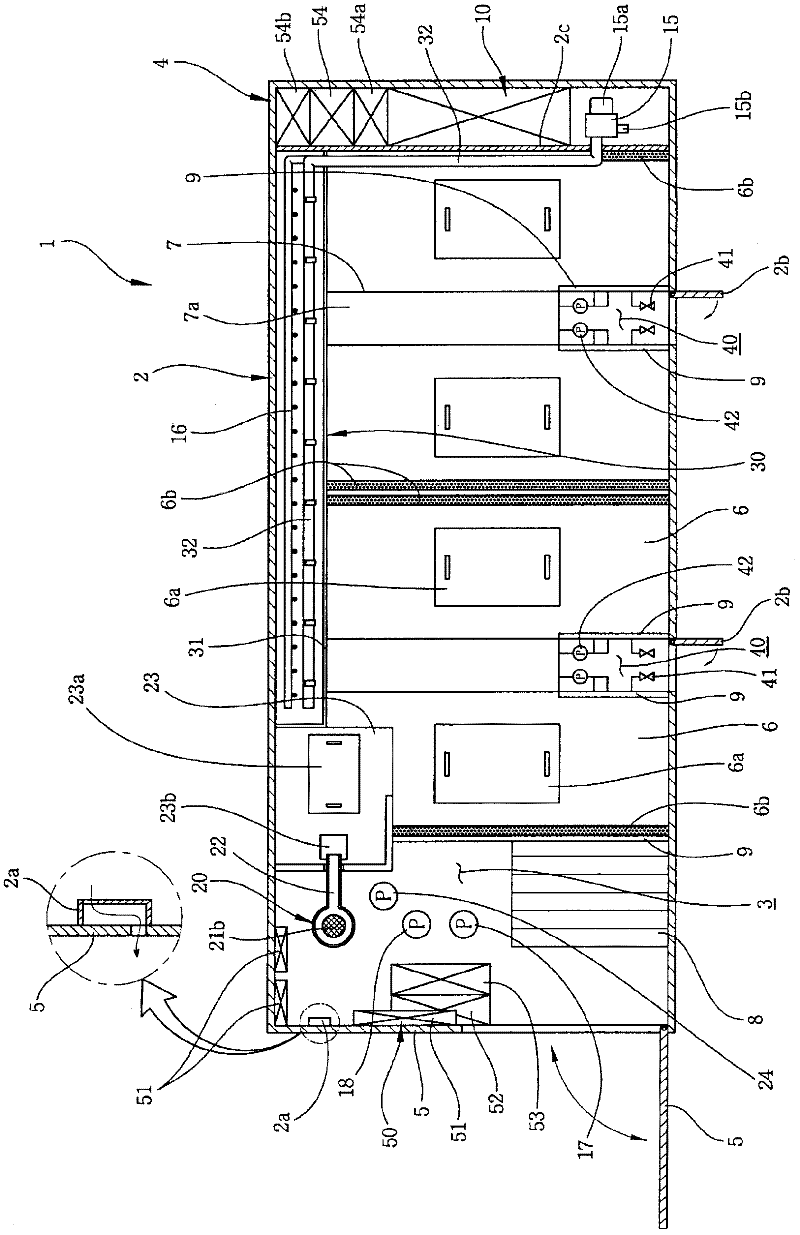

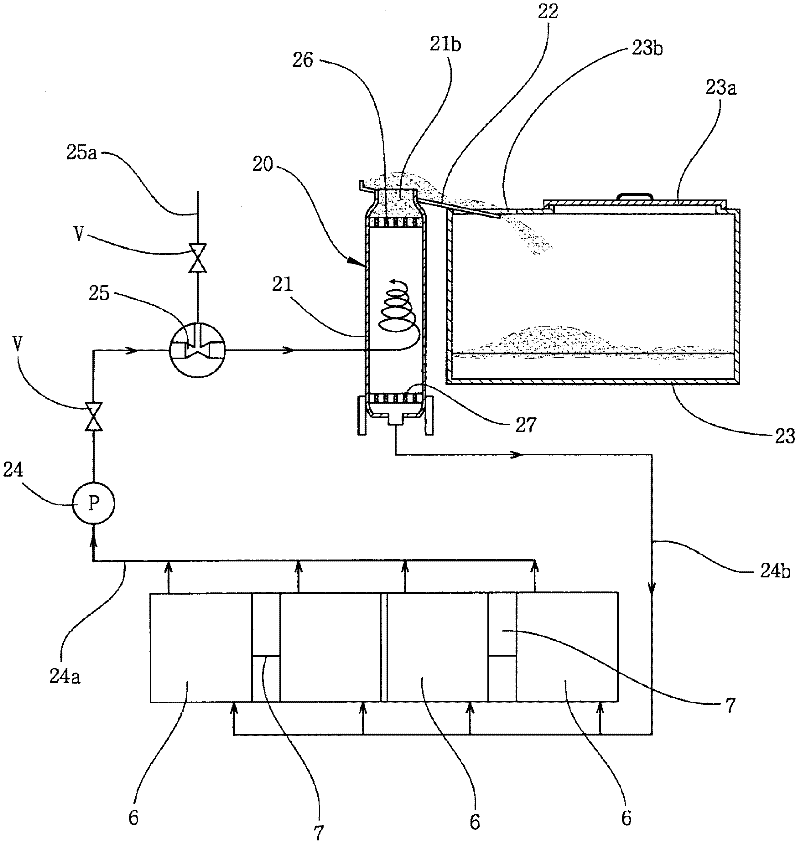

[0013] In other words, a general live fish tank uses FRP (

Fiber Reinforced Plastic) material and is set by lamination work, and after the lamination work for manufacturing the live fish tank is partially performed, setting of the

evaporator and

refrigerant piping are performed next After the above process is repeated several times, the finishing work and other complicated and tedious work are finally performed.

[0014] In the process of installing the live fish tank inside the live fish container as described above, the work of arranging and fixing the

evaporator on the bottom surface or side wall of the live fish tank is cumbersome, and the material for the evaporator needs to be

corrosion-resistant The material is expensive

titanium, and the length of the

refrigerant piping made of the expensive

titanium tube will be unnecessarily long, resulting in a waste of materials and an increase in the unit price of equipment

[0015] Also, during the transportation of the live fish container by the trailer or the loading or unloading of the live fish container, the protruding evaporator surface in the water tank may cause damage to the live fish due to vibration or shock acting on the live fish container, etc. , cause live fish

disease or reduce the commercial value of live fish, because the temperature around the refrigerant

pipe of the evaporator is too low compared with the temperature of live fish water, so live fish suffer from the pressure caused by temperature and die or die

[0016] At the same time, when a large number of fish scales are formed along the surface of the refrigerant piping constituting the evaporator, there is a possibility that the

pollution of the live fish water will be aggravated, the heat exchange efficiency and cooling performance by the evaporator will be reduced, and the temperature of the live fish water will be lowered. It is not easy to reduce, and it will also cause adverse effects on the fresh and

safe storage and transportation of live fish during transportation

[0017] In addition, as the refrigerant

pipe is extended from the drive unit to the evaporator installed in each live fish tank, it is necessary to perform waterproof sealing work together with a special heat insulating material to prevent the refrigerant

pipe from being corroded by live fish water belonging to

seawater. Therefore, there are problems in that the installation cost of the live fish water cooling device is further increased; and since there are many welded parts and connecting parts for connecting a plurality of refrigerant pipes, when subjected to shock and vibration applied during the transportation of the live fish container, The risk of refrigerant leakage will increase, and when the refrigerant leaks, all live fish will be suffocated; and the confirmation of the leakage site and the repair work are also more cumbersome

[0032] Therefore, there is a problem that the control panel, battery, converter, etc. belonging to the control part of the electric or electronic device are easily corroded and damaged by the

moisture inside the cargo compartment containing a large amount of salt, and the failure of the control part frequently occurs. or misoperation, thus exposing many problems in the safe transfer of live fish using the live fish container

[0033] In order to prevent the above-mentioned problems, it is necessary to insert the electronic control products of the control panel or the battery and the converter into the inside of the closed casing to prevent contact with the internal air of the cargo compartment. In this case, due to the ineffective cooling The heat generated during the operation of electronic control products or batteries and

converters can lead to malfunctions or misoperations caused by overheating of the control part

[0034] In particular, with regard to the live fish container, since personnel cannot enter the interior of the cargo compartment during its transportation, long-term unmanned operation is required, but due to the

corrosion or overheating of the control part installed inside the cargo compartment, there will not only be Cause the failure of the control part, even cause a fire, cause all the live fish to suffocate during transportation, and the cost of repair and maintenance of the control part will also be excessively spent

Login to View More

Login to View More  Login to View More

Login to View More