Heat dissipation device using latent heat functional fluid and heat dissipation method thereof

A technology of functional fluid and heat dissipation device, applied in semiconductor devices, electric solid state devices, cooling/ventilation/heating transformation, etc., can solve the problems of difficulty in heat dissipation or increase in cost, and achieve the effect of extending heat dissipation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

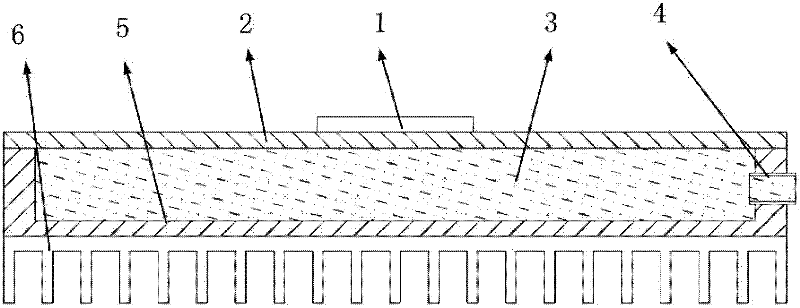

[0038] figure 1 It is a structural schematic diagram according to Embodiment 1 of the present invention, such as figure 1 As shown in , the heat dissipation device is composed of a discontinuous working heat source 1 , a cover plate 2 , a latent heat type functional fluid 3 , a liquid injection pipe 4 , and a housing 5 . The discontinuous working heat source 1 is arranged on the outer surface of the cover plate 2 or the housing 5 , and the discontinuous working heat source 1 is arranged on the outer surface of the cover plate 2 in this embodiment. The number of discontinuously working heat sources 1 can be one or more than two, and the number of heat sources 1 in this embodiment is one. The cover plate 2 is connected and closed with the housing 5 to form an inner chamber, and the latent heat functional fluid 3 is injected into the inner chamber through the liquid injection pipe 4 . The cover plate 2 can be a flat plate or have one or more protrusions protruding toward the in...

Embodiment 2

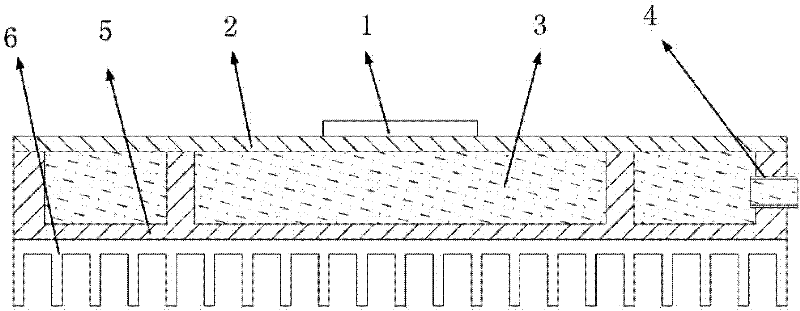

[0050] The difference between the second embodiment and the first embodiment is that in the second embodiment, there are pillars on the bottom surface of the casing 5 opposite to the cover plate. The pillars protrude toward the inner chamber and are connected with the cover plate. Improve the mechanical strength of the cooling device, see figure 2 .

Embodiment 3

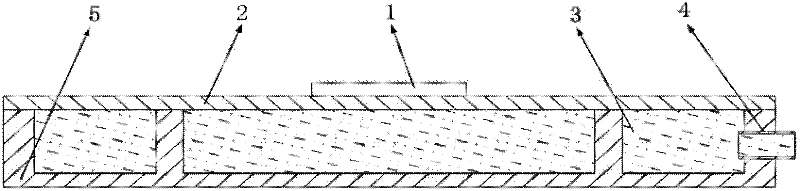

[0052] The difference between the third embodiment and the second embodiment is that heat dissipation without fins is realized in the embodiment. In Embodiment 3, the working time of the discontinuously working heat source 1 is relatively short, the non-working time is relatively long, the latent heat functional fluid 3 stores less heat, and the heat dissipation device dissipates heat for a long time through the heat dissipation area of the cover plate 2 and the housing 5 It can meet the requirements of heat dissipation, without the need of heat dissipation fins 6, and realizes the technical effect of no fins. For details, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com