Piezoelectricity ceramic piece and piezoelectricity ceramic loudspeaker adopting same

A technology of piezoelectric ceramic sheets and piezoelectric ceramics, applied in the direction of piezoelectric/electrostrictive transducers, sensors, electrical components, etc., can solve the problems of poor bass reproduction, poor low-frequency characteristics, and large distortion of speakers. Achieve the effect of good intermediate frequency sound quality, improved low frequency characteristics, and low distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

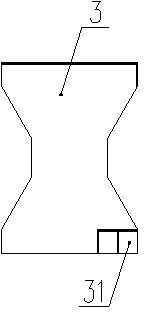

[0015] see figure 1 As shown, the piezoelectric ceramic sheet of the present invention is characterized in that: the shape of the piezoelectric ceramic sheet 3 is a butterfly shape with two ends wide and the middle shrinking inward. Moreover, in this embodiment, the lead-out electrode 31 of the piezoelectric ceramic sheet 3 is arranged at the end of the piezoelectric ceramic sheet with a wider size.

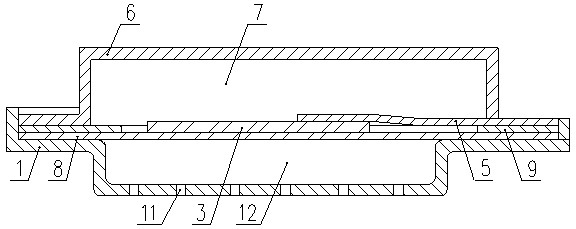

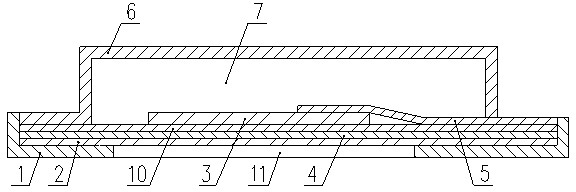

[0016] see figure 2 As shown, a preferred embodiment of the piezoelectric ceramic loudspeaker prepared by the piezoelectric ceramic sheet according to the present invention includes: a front cover 1 with a sound-transmitting through hole 11 in the middle part, and an elastic vibrator is fixedly arranged in the front cover 1. Diaphragm 8, the middle part of the front cover 1 is provided with the concave cavity 12 that is conducive to the vibration of the elastic diaphragm 8, and the elastic diaphragm 8 is provided with the butterfly-shaped piezoelectric ceramic sheet 3 and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com