Producing method of water-proof connector

A technology of waterproof connector and manufacturing method, which is applied in the manufacture of contact box/base, base/housing, etc., can solve the problems of intrusion, troublesome installation work, and inability to use installation methods, etc., and achieve efficient and simple manufacturing and easy filling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

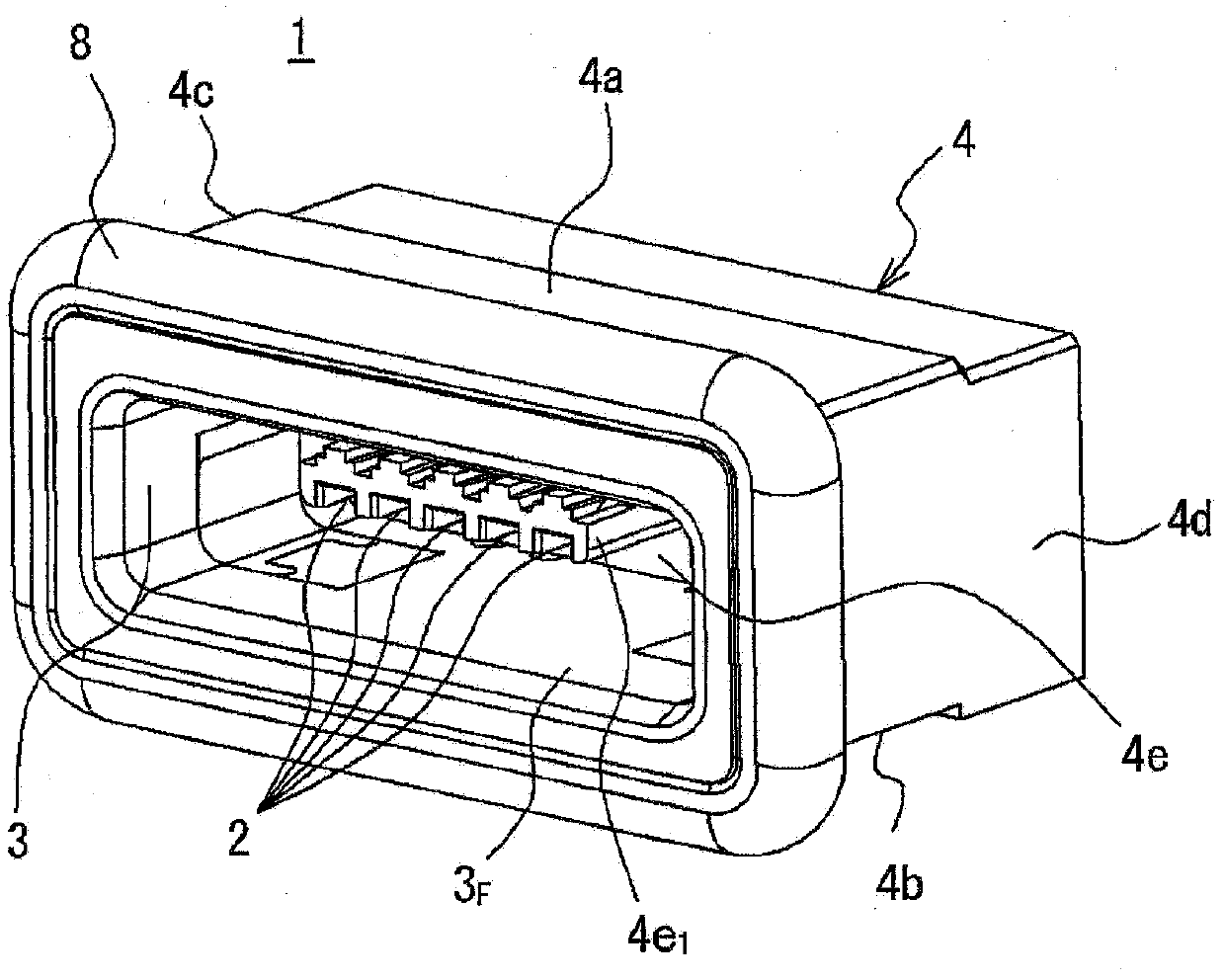

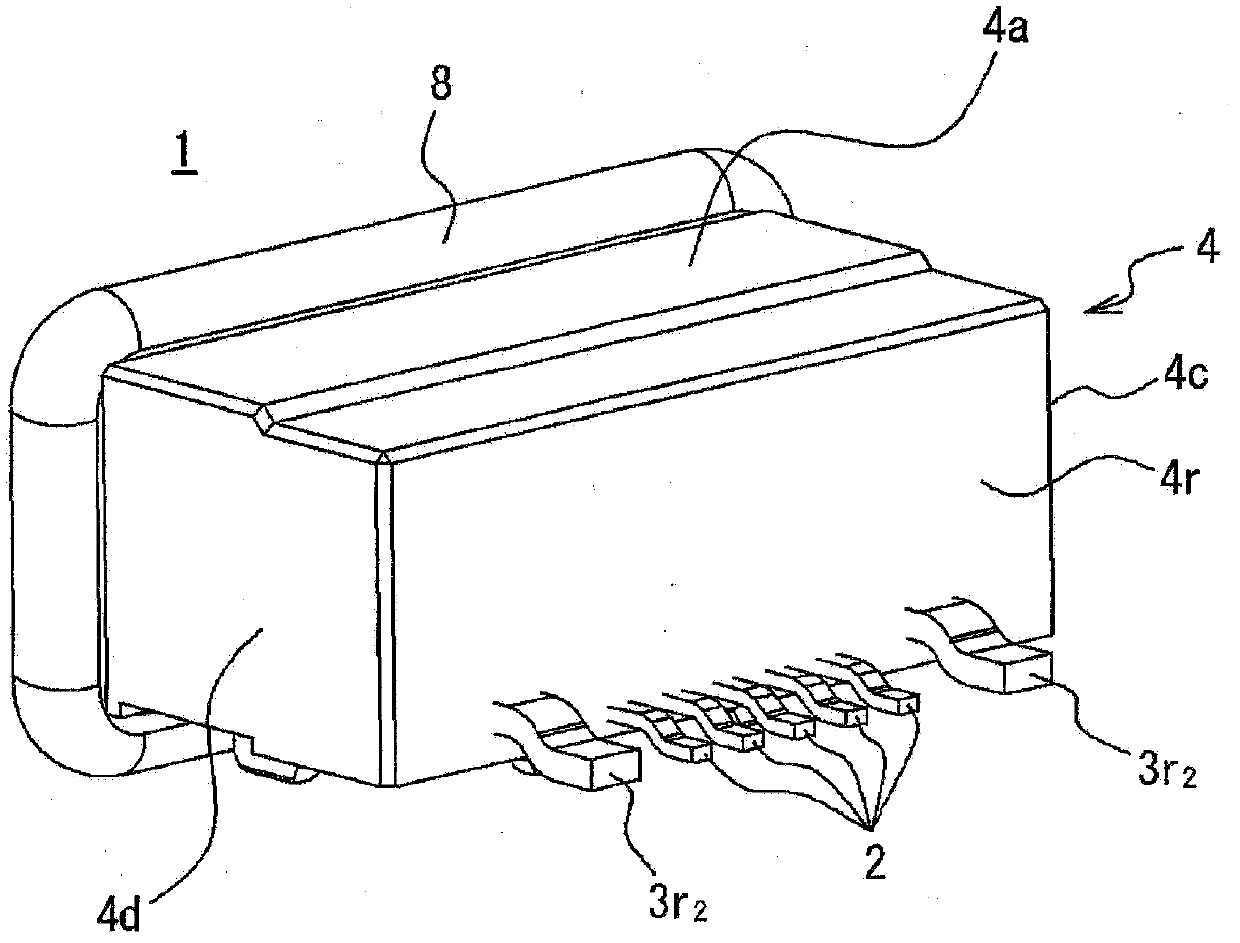

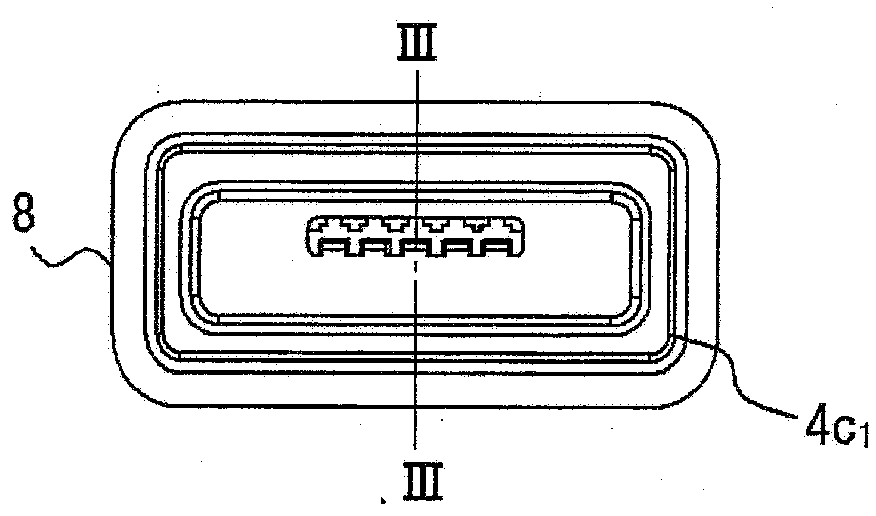

[0076] refer to Figure 1A ~ Figure 3C , and the waterproof connector according to the embodiment of the present invention will be described. in, Figure 1A and Figure 1B Showing the waterproof connector according to Embodiment 1 of the present invention, Figure 1A is a front perspective view viewed from the front, Figure 1B It is a rear perspective view viewed from the rear, Figure 2A-Figure 2E yes Figure 1A and Figure 1B A detailed drawing of the waterproof connector, Figure 2A is the main view, Figure 2B is a top view, Figure 2C is a bottom view, Figure 2D is the left view, Figure 2E is the right side view, Figure 3A is along Figure 2A The sectional view after cutting along the line III-III, Figure 3B yes Figure 3A An enlarged cross-sectional view of a part of Figure 3C yes Figure 3A An enlarged cross-sectional view of part IIIC.

[0077] A waterproof connector (hereinafter referred to as a connector) 1 according to Embodiment 1 of the pres...

Embodiment approach 2

[0119] refer to Figure 18A-Figure 18G , and the waterproof connector according to Embodiment 2 of the present invention will be described. Figure 18A-Figure 18G A waterproof connector according to Embodiment 2 of the present invention is shown, Figure 18A is the main view, Figure 18B is a top view, Figure 18C is a bottom view, Figure 18D is a side view of one side, Figure 18E is the side view of the other side, Figure 18F is the back view, Figure 18G yes Figure 18A The cross-sectional view of line XVIII-XVIII.

[0120] This connector 1A has a plurality of contacts 2', and a case 4' which is integrally molded by embedding and fixing these contacts in a mold and using an electrical insulating resin. The gap is filled with a waterproof sealant to perform a waterproof seal. This connector 1A is manufactured using the same manufacturing steps I to V as those of the connector 1 described above. Also in this connector, the contacts and the housing can be brought i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com