Organic/inorganic hybridization solar cell based on zinc oxide (ZnO) homogeneous core-shell structure nanorod array and production method thereof

A nanorod array and solar cell technology, applied in the field of nanomaterials and energy, to achieve the effects of improved conversion efficiency, increased open circuit voltage, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Preparation of ZnO nanorod arrays.

[0044] (1-1) Preparation of ZnO dense film:

[0045] First, etch the ITO on the ITO conductive glass (ITO thickness is 100-120nm, ≤15Ω / □) with concentrated hydrochloric acid and Zn powder to 12×3mm 2 Thin strips; ultrasonically cleaned with acetone, isopropanol, and ultrapure water, and dried with dry nitrogen before use.

[0046] 0.16 g of zinc acetate [Zn(CH 3 COO) 2 2H 2 O] was dissolved in 1 g of water, and after complete dissolution, 4 ml of absolute ethanol was added, and then 100 μl of glacial acetic acid was added dropwise; the mixture was stirred at room temperature for 2 hours to obtain a colorless, clear and transparent solution. The above solution was spin-coated on ITO glass (2000 rpm, 60 seconds), repeated four times to obtain a uniform film, and then calcined in a muffle furnace at 350° C. for 20 minutes to obtain a dense ZnO film.

[0047] (1-2) Preparation of ZnO nanorod arrays:

[0048] The ITO glas...

Embodiment 2

[0051] Example 2: Preparation of ZnO-NR-QD homogeneous core-shell nanorod arrays.

[0052] (2-1) Preparation of ZnO nanorod array: Same as Example 1.

[0053] (2-2) Preparation of ZnO-NR-QD homogeneous core-shell nanorod arrays:

[0054] At room temperature, the ZnO nanorod array was placed in a 100 mL polytetrafluoroethylene-lined autoclave filled with 80 mL of zinc acetate ethanol solution with a concentration of 0.02 mol / L, sealed and reacted in an oven at 95 °C for 2.5 hours. After the kettle was cooled to room temperature, the sample was taken out and rinsed with absolute ethanol, and dried with nitrogen to obtain a ZnO-NR-QD homogeneous core-shell nanorod array (ie, ZnO-NR-QD-NA);

[0055] (2-3) Characterization of the product:

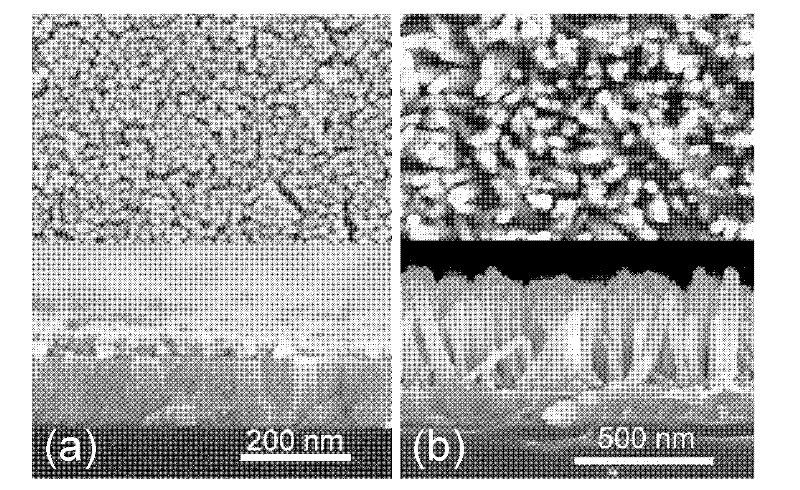

[0056] XRD result (attached Figure 4 ) showed that the composition of the product obtained after the ZnO nanorod array was reacted in an autoclave was only wurtzite structure ZnO, and showed polycrystalline diffraction characteristics; SEM res...

Embodiment 3

[0057] Example 3: Preparation of N719-modified ZnO-NR-QD homogeneous core-shell nanorod arrays.

[0058] (3-1) Preparation of ZnO nanorod array: Same as Example 1.

[0059] (3-2) Preparation of ZnO-NR-QD nanorod array with homogeneous core-shell structure: same as Example 2.

[0060] (3-3) Preparation of N719-modified ZnO-NR-QD homogeneous core-shell nanorod arrays:

[0061] At room temperature, the ZnO-NR-QD homogeneous core-shell structure nanorod array was placed in a container containing 80mL with a concentration of 5×10 -6 mol / L zinc acetate ethanol solution in a 100mL autoclave lined with polytetrafluoroethylene, sealed and reacted in an oven at 80°C for 8 hours, after the autoclave was cooled to room temperature, the sample was taken out and rinsed with absolute ethanol, nitrogen Blow dry to obtain the ZnO-NR-QD homogeneous core-shell structure nanorod array (ie, ZnO-NR-QD-N719-NA) modified by N719 molecules;

[0062] (3-4) Characterization of the product:

[0063] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com