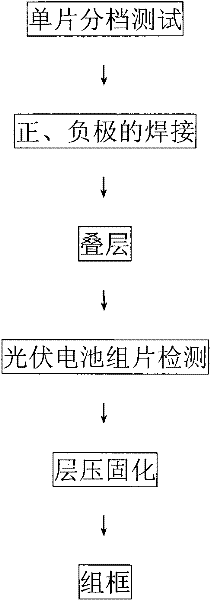

Production process for photovoltaic cell assembly

A photovoltaic cell and production process technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of shortened service life, many bubbles in photovoltaic cells, and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] The following is a further description of the present invention by taking a photovoltaic cell module with a power of 90W and a module area of 1191mmx538mm as an example in conjunction with the accompanying drawings:

[0006] First of all, the photovoltaic cells with a size of 125mmx125mm are graded and tested, and 36 single photovoltaic cells of 2.5W with similar performance are selected, and the positive and negative electrodes are welded with 9 pieces in the length direction and 4 pieces in the width direction; the welding is completed Finally, the structure of TPT-EVA-photovoltaic cell group-EVA-tempered glass is laminated, and sent to the EL solar module tester for photovoltaic cell group inspection. There are no defects, splits, low-efficiency sheets or After the solder joint is empty, send it to the laminator for lamination and curing. Before closing the lid, the upper chamber is vacuumed at -0.02Mpa, and the lower chamber is vacuumed at -0.07Mpa after the lid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com