Thin-film solar cell and method for manufacturing the same

A technology for solar cells and manufacturing methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as affecting the open-circuit potential fill factor of solar cells, photoelectric conversion efficiency, weakening electric fields, etc., so as to improve efficiency performance, simplify processes, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The detailed features and advantages of the present invention are described in detail below in the embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the content disclosed in this specification, the scope of claims and the accompanying drawings , any person skilled in the art can easily understand the related objects and advantages of the present invention.

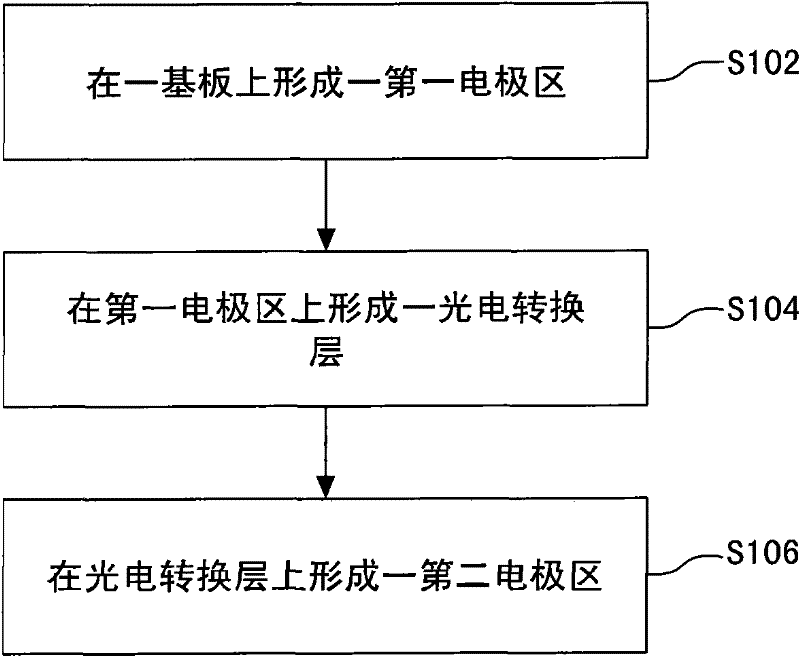

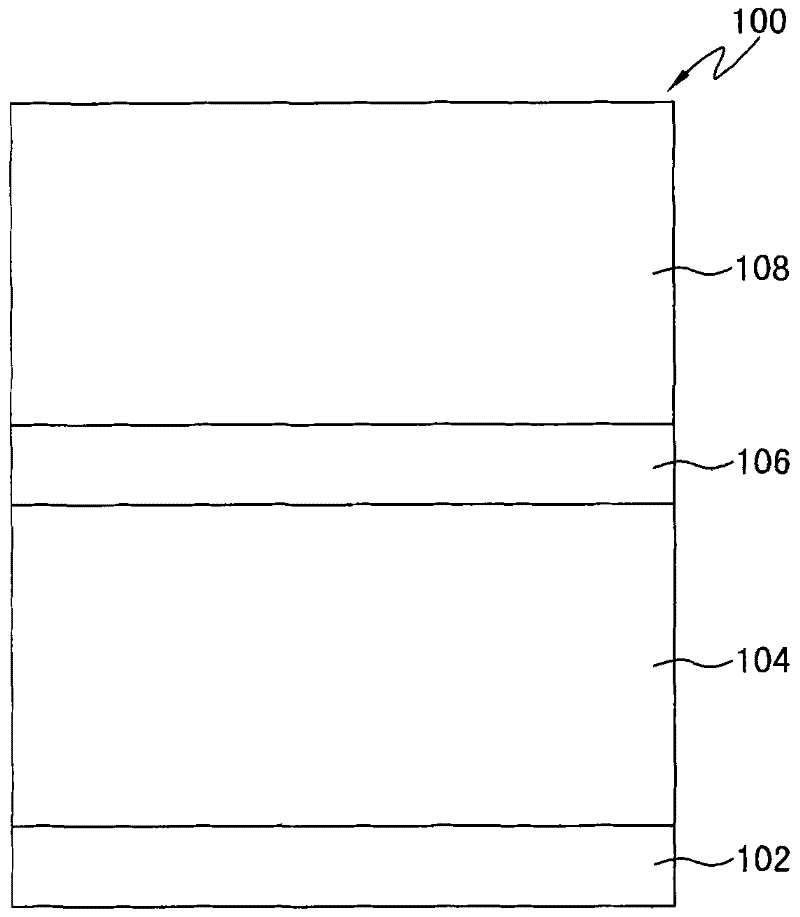

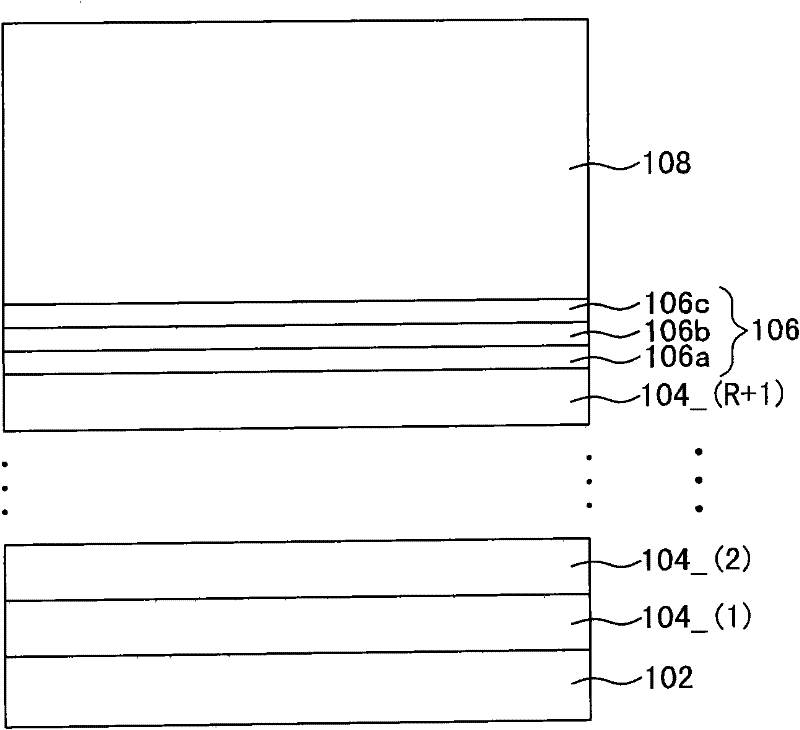

[0049] figure 1 It is a flow chart of the steps of the manufacturing method of the thin-film solar cell according to the embodiment of the present invention. This manufacturing method is suitable for forming a front electrode or a back electrode with a graded dopant concentration in the solar cell, thereby maintaining better photoelectricity of the solar cell. conversion efficiency. The manufacture method of the thin-film solar cell proposed by the present invention mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com