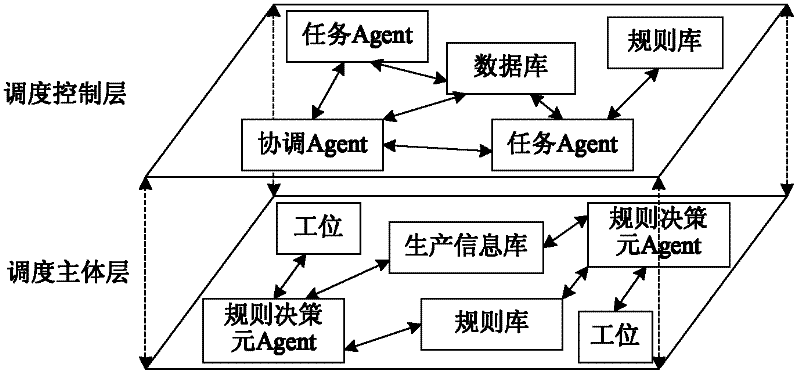

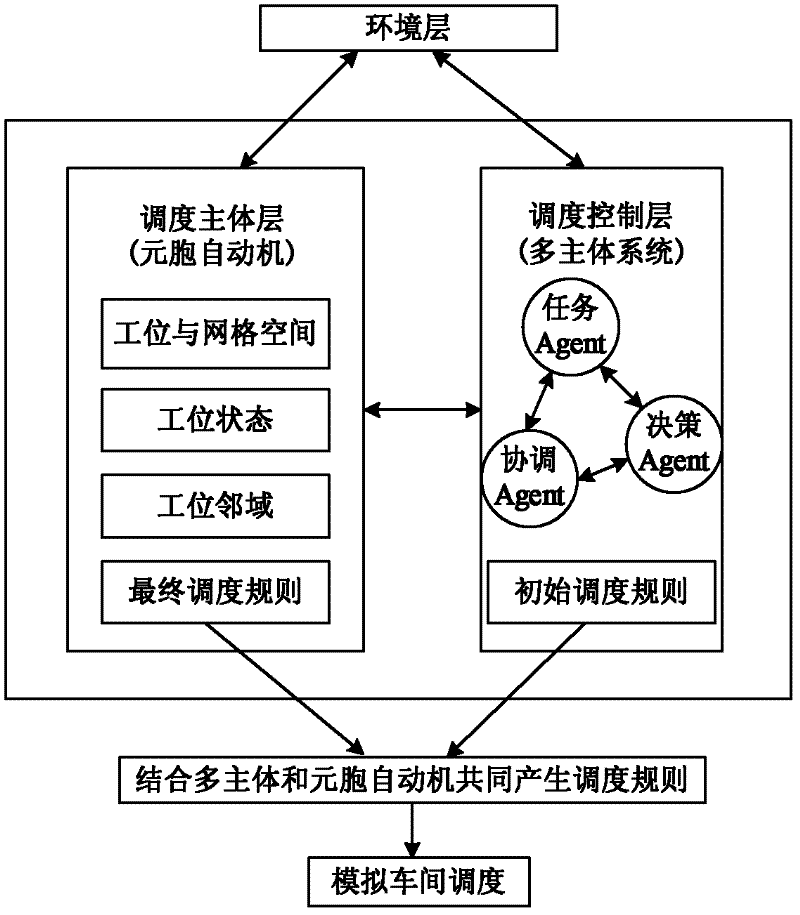

Method for carrying out dispatching control on multi-variety multi-process manufacturing enterprise workshop on basis of ACA (Automatic Circuit Analyzer) model

A control method and workshop scheduling technology, applied in the field of workshop scheduling control, can solve the problems of slow convergence, poor applicability, and poor practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

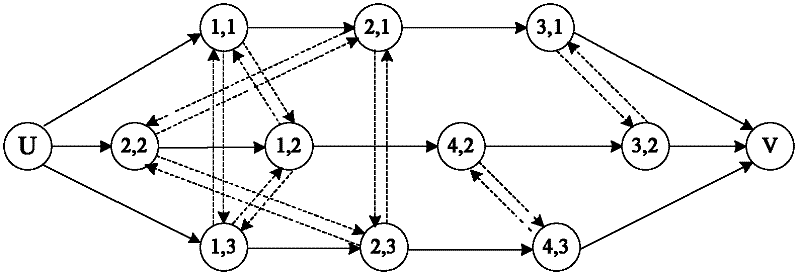

Method used

Image

Examples

example

[0103] Example: A company is an enterprise specializing in R&D and production of various tubular heating elements, high-power and high-performance composite heating elements, metal-based printed circuit heating elements and more than a dozen series of more than 400 products, which are widely used in various household appliances . Among them, there are not only products that can be processed by a single unit, but also products that can be completed by combining four or five parts. It adopts a typical multi-variety and multi-process production mode. With the development of the company and the diversification of customer requirements, the research on its workshop scheduling problem has become more and more important and necessary. However, due to the medium size of the company, it does not pay much attention to the scheduling link and lacks a formal scheduling system. and mechanism, so the proposed agent-cellular automata model of the multi-variety and multi-process manufacturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com