Analysis method for calculating liquid weight

An analytical method and gravimetric technology, applied in the direction of weighing, using material absorption weighing, weighing equipment with special properties/forms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

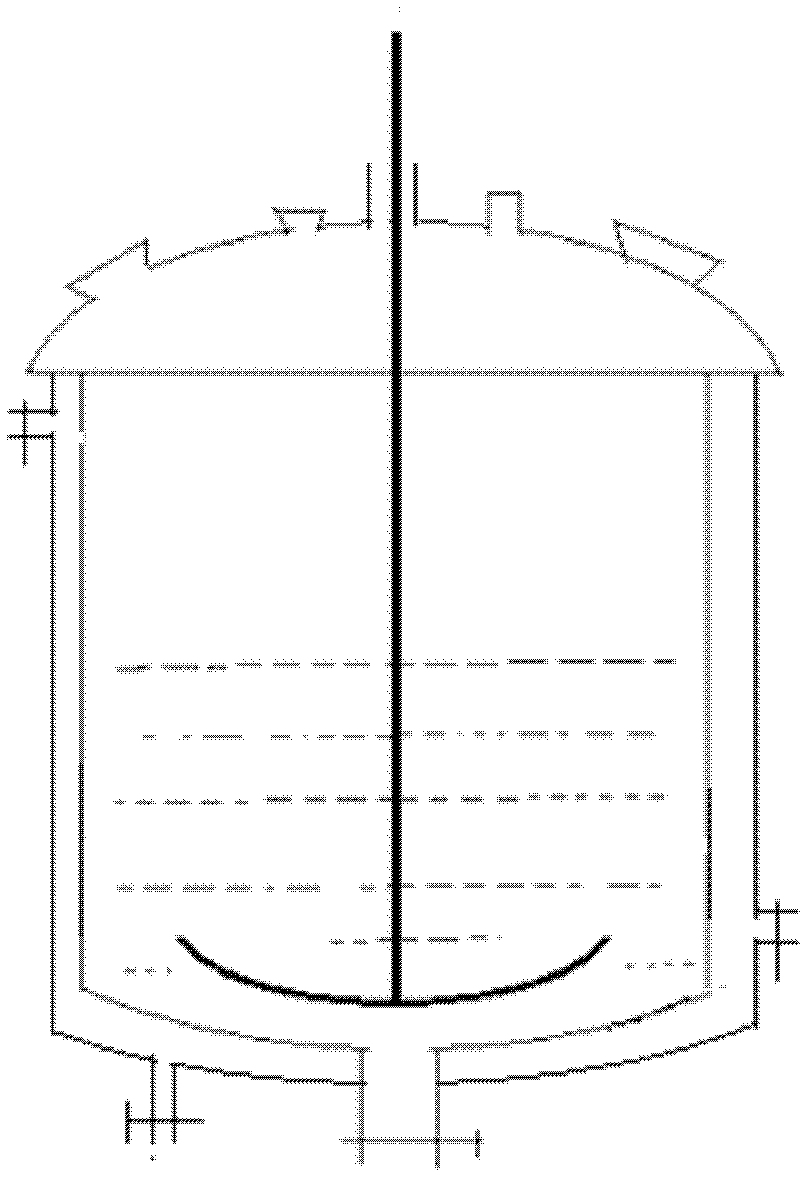

Image

Examples

Embodiment 1

[0021] In the process of producing cobalt naphthenate, the solvent is No. 200 solvent gasoline, and the qualified content of cobalt in the product is 4%. After the production process was completed, through distillation and dehydration, the cobalt content was 4.36% (a%). After adding 30 kilograms (W) of No. 200 solvent gasoline, the result of the second analysis showed that the cobalt content was 4.11% (b%).

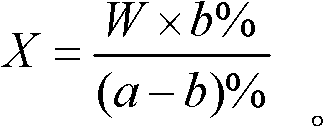

[0022] by formula Calculate, the material in the kettle is 493.2 kilograms (X), and the cobalt weight is 21.50 kilograms.

[0023] According to the weight of cobalt, it can be seen that the weight of the qualified product should be 537.5 kg. Owing to having added 30 kilograms of No. 200 solvent gasoline, the material weight in the kettle is 523.2 kilograms, and then adding 14.3 kilograms of No. 200 solvent gasoline can obtain 537.5 kilograms of qualified products.

Embodiment 2

[0025] According to embodiment 1, through distillation dehydration, cobalt content is 4.33%, after adding No. 200 solvent naphtha of 30 kilograms, the result of second analysis, cobalt content is 4.16%.

[0026] After calculation, the material in the kettle is 734.12 kilograms, and the cobalt weight is 31.79 kilograms.

[0027] According to the weight of cobalt, the weight of qualified product should be 794.75 kg. Owing to having added No. 200 solvent gasolines of 30 kilograms, the material weight in the kettle is 764.12 kilograms, then adding No. 200 solvent gasolines of 30.63 kilograms can obtain the qualified product of 794.75 kilograms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com