Firework assembling machine

A technology for assembling machines and fireworks, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as low work efficiency, high labor intensity, and specification errors, so as to avoid cylinder rolling and error accumulation, and reduce maintenance and adjustment workload The effect of small size and shortened processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

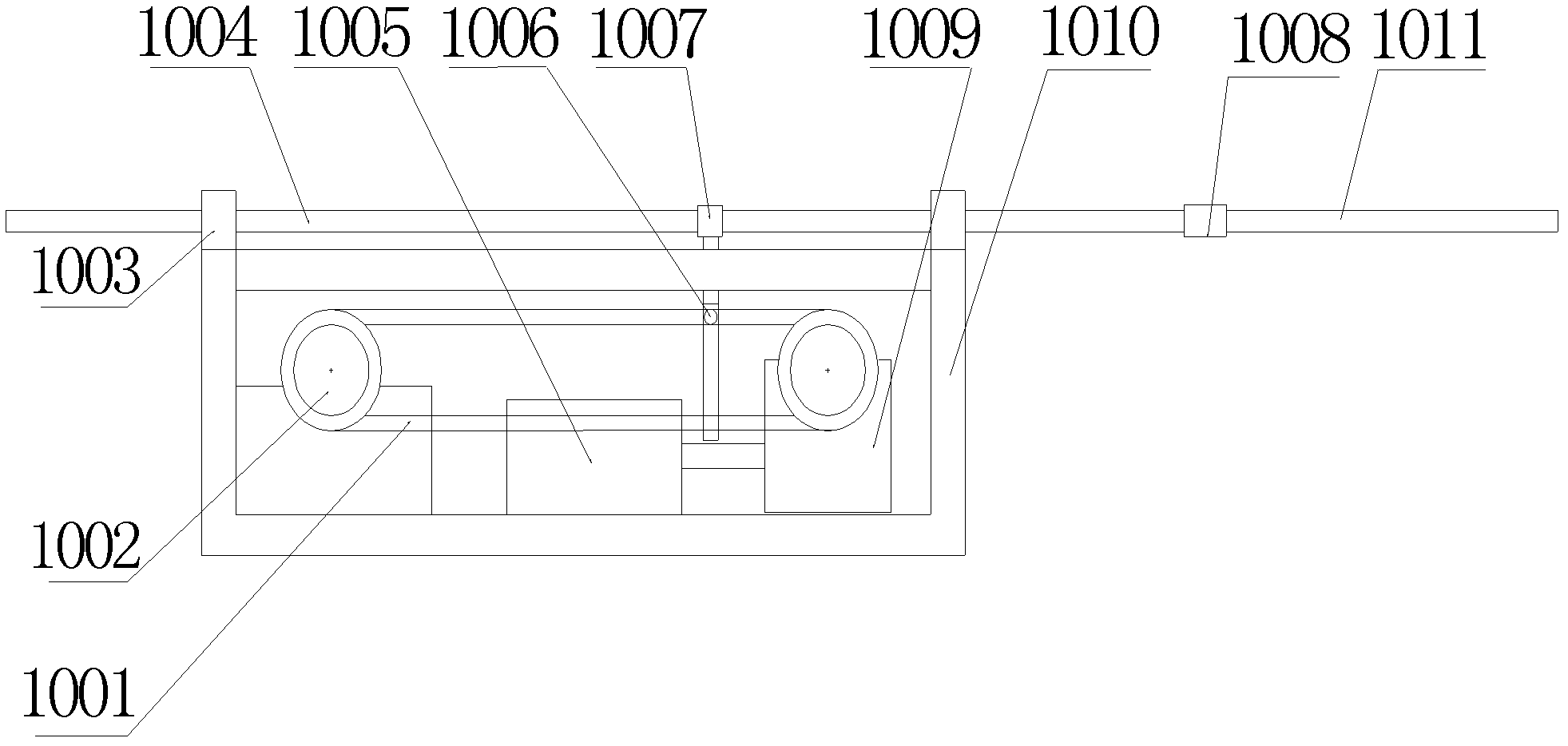

[0058] see Figure 1-2 , reflecting a specific structure of the present invention, the fireworks assembly machine includes a material discharge system 300 , a conveying roller set 400 and a moving insertion system 500 arranged in sequence along the worktable 200 of the main frame 100 , and the rear of the worktable 200 A pusher device 600 is provided to work correspondingly with the blanking and discharging system 300, and a forming system 700 is provided in front of the working table 200 to work correspondingly with the mobile insertion system 500 (here, the "front" and "rear" refer to the advancing direction of the fireworks tube) the front, and vice versa); the discharge system 300 discharges a plurality of fireworks tubes to the work surface 200 at one time according to the required quantity and arranges them in rows; The fireworks tubes are pushed out in a row along the direction parallel to the central axis of the fireworks tube, and are sent to the punching and insertin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com