Combination method for aviation heater

A combination method and heater technology, applied in electric furnace heating, lighting and heating equipment, furnace components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The invention belongs to the arrangement of heating elements of an industrial resistance furnace, in particular, the optimized arrangement of the heating elements improves the furnace temperature uniformity of the industrial resistance furnace for aviation.

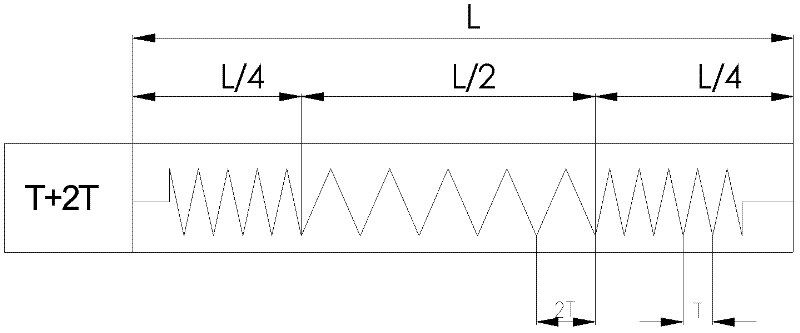

[0055] According to the size of the furnace hearth, you can choose Figure 4 to Figure 38 Several types of furnaces are combined (see Table 1 to Table 3) to form the heating zone of the furnace to meet the requirement of furnace temperature uniformity ≤ 5 °C.

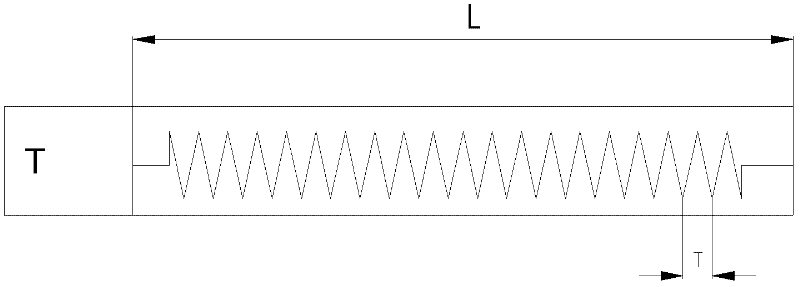

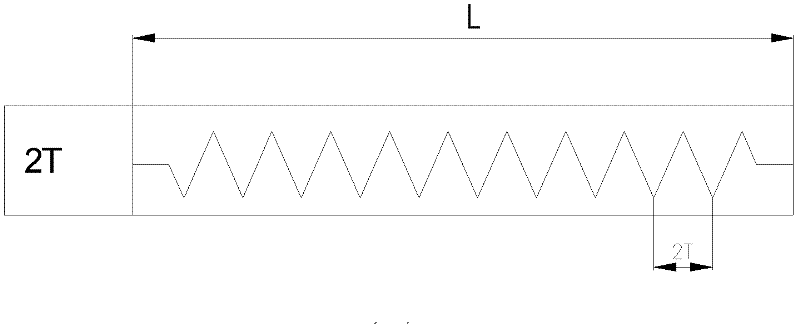

[0056] In the present invention, the units of three kinds of heating elements are combined into various heating zones to meet the requirement that the furnace temperature uniformity is ≤5°C. Example A heating zone is composed of the following units, and the maximum number of units in the heating zone is 6.

[0057] The combination method of the aviation heater in the embodiment of the present invention is characterized in that several heating unit areas are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com