Light alloy semi-continuous casting device and method under composite action of shear and magnetic field

A compound effect and light alloy technology, applied in the field of light alloy semi-continuous casting, can solve the problems of reduced temperature field uniformity control ability, poor ingot resistance to cracks, weak electromagnetic field shearing effect, etc., to increase effective nucleation The effect of reducing particle size, increasing the yield, and refining the alloy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

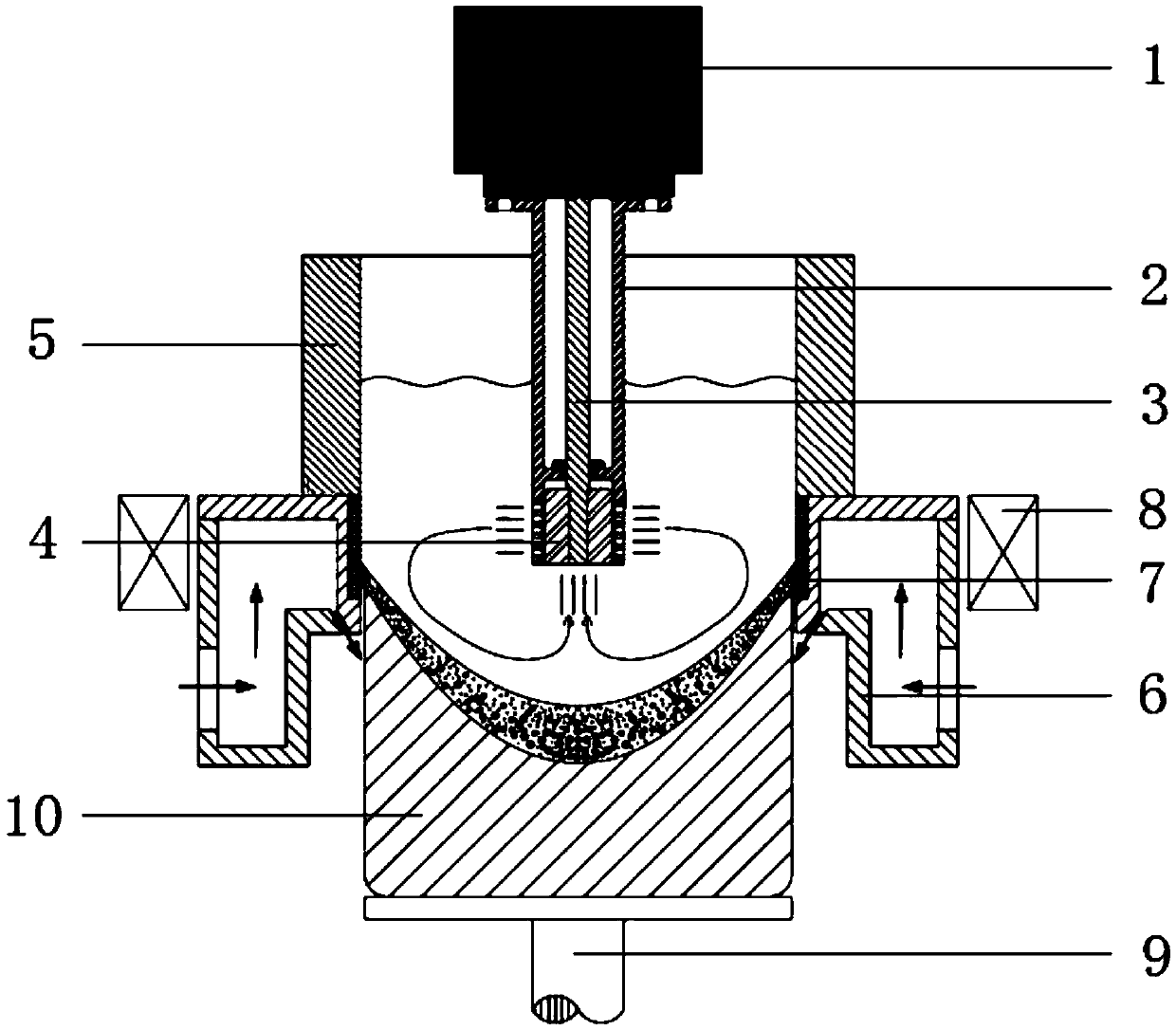

[0029] Such as figure 1 As shown, a light alloy semi-continuous casting device under the compound action of shear and magnetic field includes a casting unit, and the casting unit includes a hot top 5, a crystallizer 6, a dummy ingot 9 and an induction coil 8, and the hot top 5 Located above the crystallizer 6, the induction coil 8 is arranged on the periphery of the crystallizer 6, a graphite ring 7 is arranged on the inner wall of the crystallizer 6, and the dummy ingot 9 is located below the crystallizer 6 and corresponds to the crystallizer 6; it is arranged above the casting unit There is a melt shearing unit, and the melt shearing unit includes a driving motor 1, a stator sleeve 2, a connecting shaft 3 and a shearing blade 4, the motor shaft of the driving motor 1 is connected with one end of the connecting shaft 3, and the shear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com