Multi-level single-component refrigeration natural gas liquefaction system and multi-level single-component refrigeration natural gas liquefaction method

A refrigeration system and natural gas technology, applied in refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problem that the construction cost of large-scale liquefaction plants cannot be effectively controlled, and solve the bottleneck of localization, and the temperature difference in the heat exchange process is uniform and effective. Can lose little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

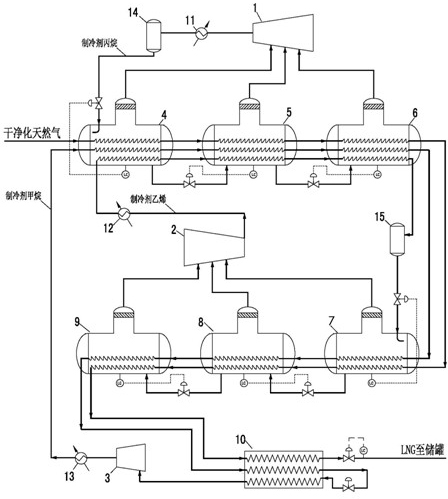

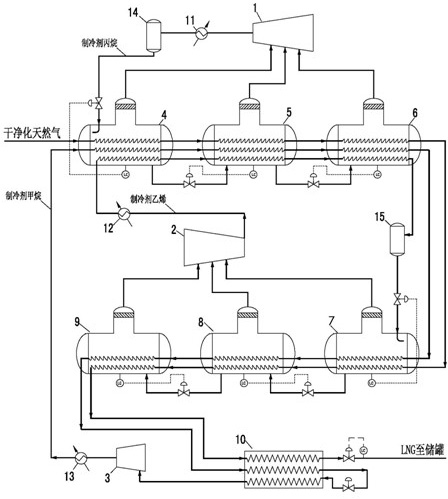

[0027] A multi-stage single-component refrigeration natural gas liquefaction system, such as figure 1 As shown, including: propane compressor 1, ethylene compressor 2, methane compressor 3, high pressure propane evaporator 4, medium pressure propane evaporator 5, low pressure propane evaporator 6, high pressure ethylene evaporator 7, medium pressure ethylene evaporator 8. Low pressure ethylene evaporator 9, natural gas subcooler 10, propane cooler 11, ethylene cooler 12, methane cooler 13, propane storage tank 14, ethylene storage tank 15. in:

[0028] Propane compressor 1, propane cooler 11, propane storage tank 14, high-pressure propane evaporator 4, medium-pressure propane evaporator 5 and low-pressure propane evaporator 6 are connected in sequence to form a propane pre-cooling system for natural gas, methane and ethylene The agent is pre-cooled.

[0029] Ethylene storage tank 15, high-pressure ethylene evaporator 7, medium-pressure ethylene evaporator 8, low-pressure eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com