Turbocharger with divided turbine housing and annular rotary bypass valve for the turbine

一种涡轮增压器、涡轮壳体的技术,应用在阀装置、滑动阀、机器/发动机等方向,能够解决难阀完全、回转阀或提升阀可控性差、发动机系统瞬态响应差等问题,达到好可控性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present disclosure will now be described more fully hereinafter with reference to the accompanying drawings, in which some, but not all embodiments of the inventions are shown. Indeed, these inventive concepts may be embodied in many different forms and should not be construed as limited to the embodiments described herein; rather, these embodiments are provided so that this disclosure will satisfy applicable statutory requirements. Like numbers refer to like elements throughout.

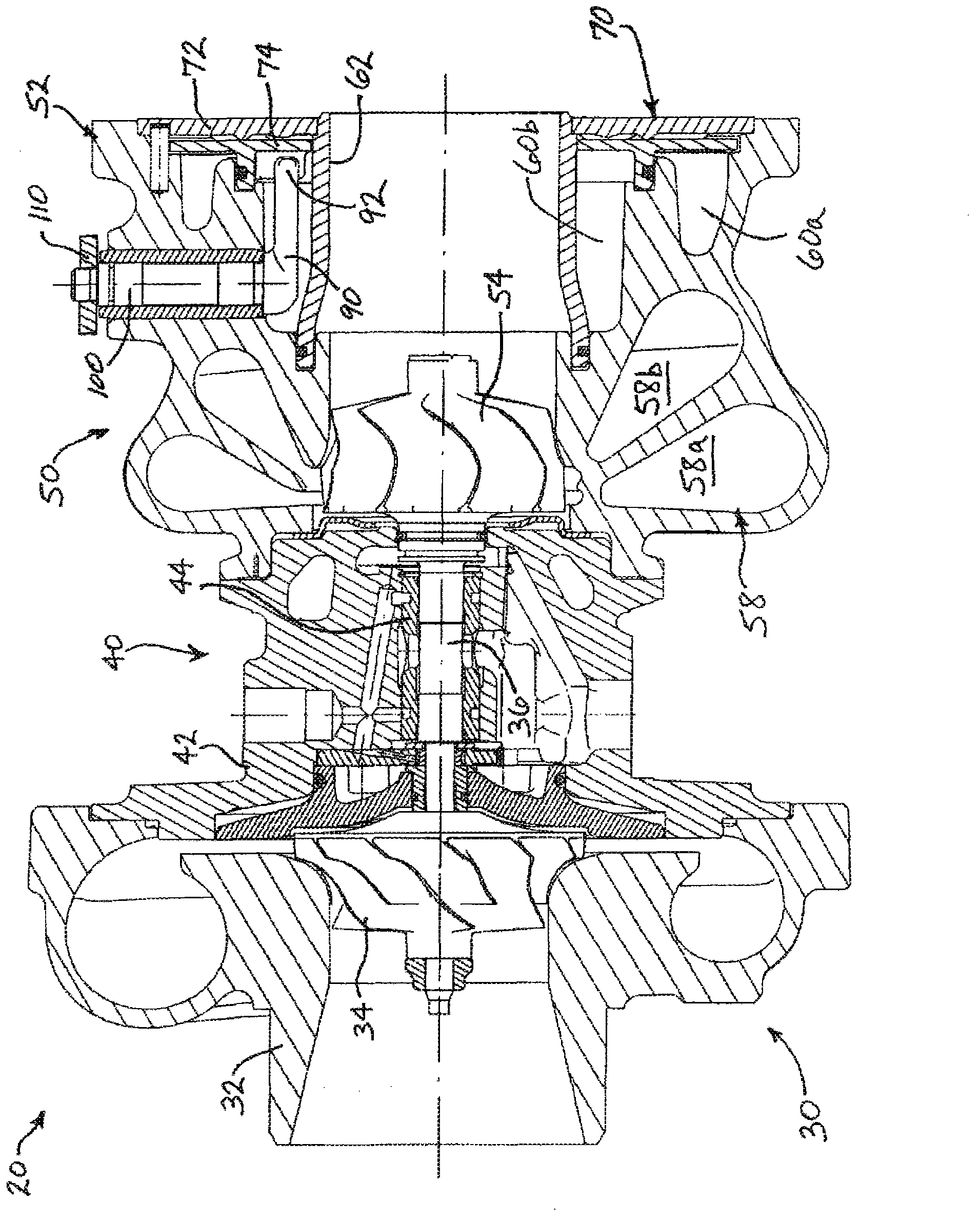

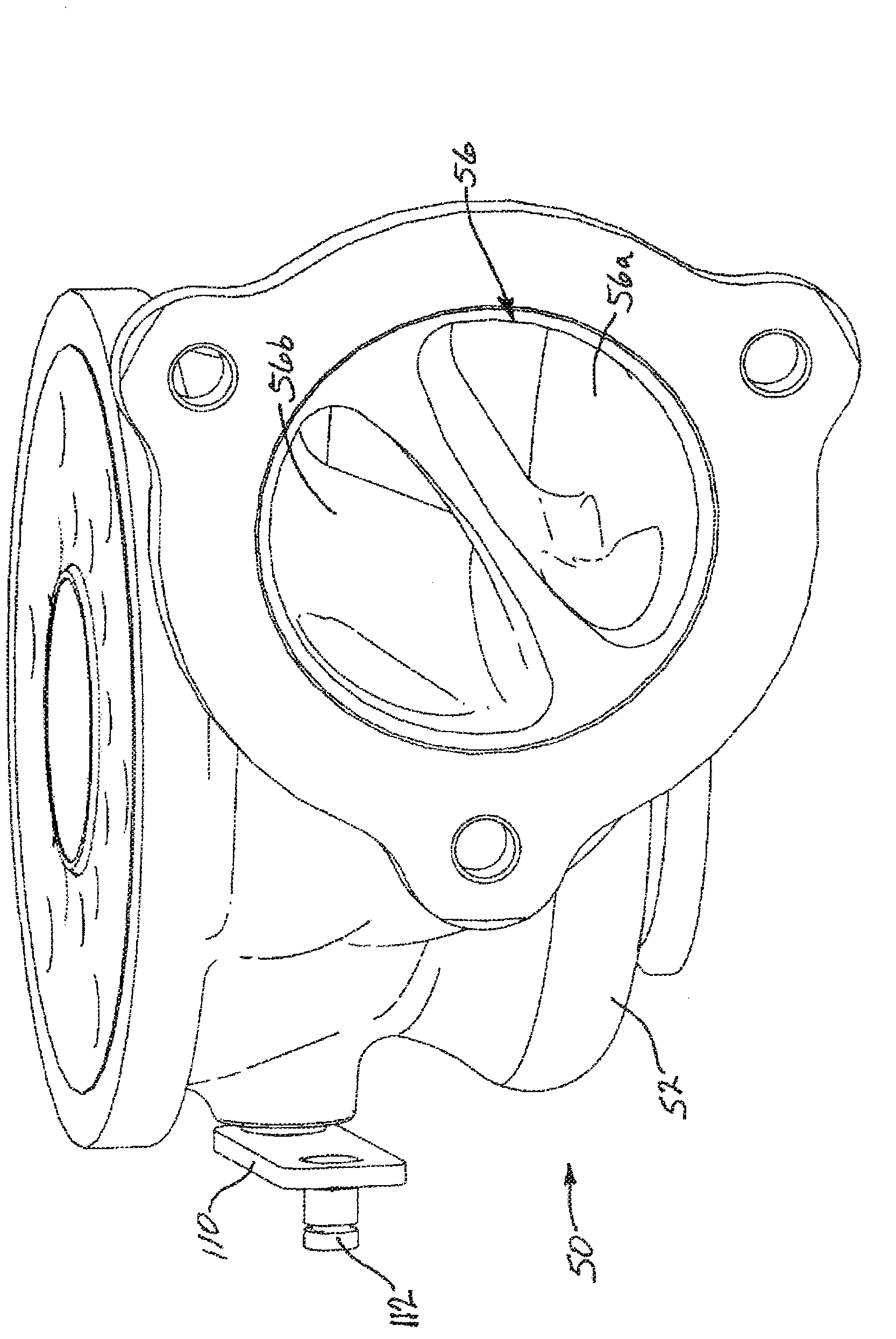

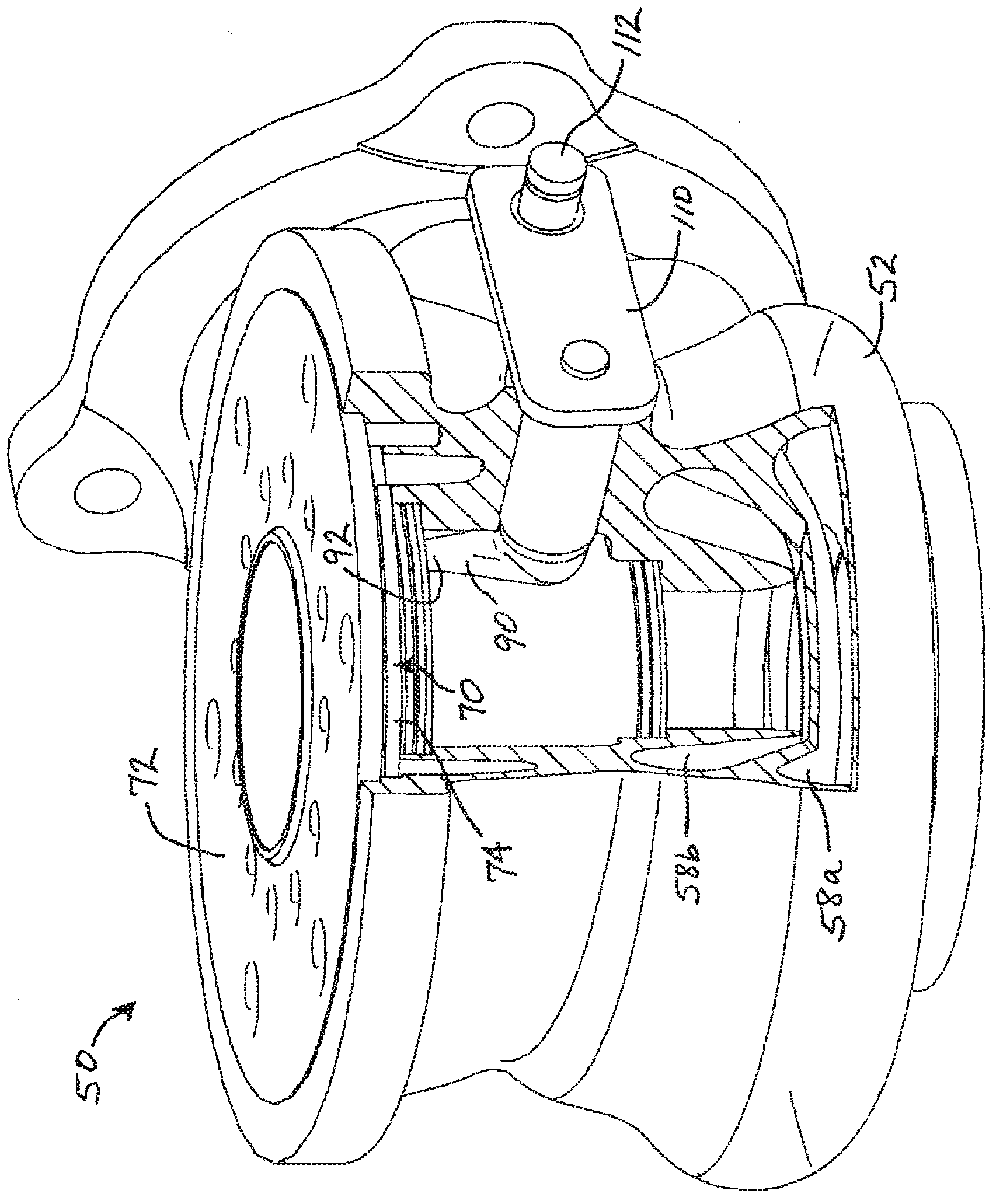

[0036] The turbocharger 20 according to one embodiment of the present invention is figure 1is shown in axial section in , and various views of a turbine assembly and components of a turbine assembly for a turbocharger are in Figure 2-13 shown in . Such as figure 1 As shown, the major subassemblies of turbocharger 20 include compressor assembly 30 , intermediate housing assembly 40 , and turbine assembly 50 . Compressor assembly 30 includes a compressor housing 32 and a compressor whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com