Fast construction method of headframe lifting system

A technology of lifting system and construction method, applied in vertical shaft equipment, earthwork drilling, mining equipment, etc., can solve problems such as long construction period, and achieve the effect of ensuring construction quality, fast speed and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

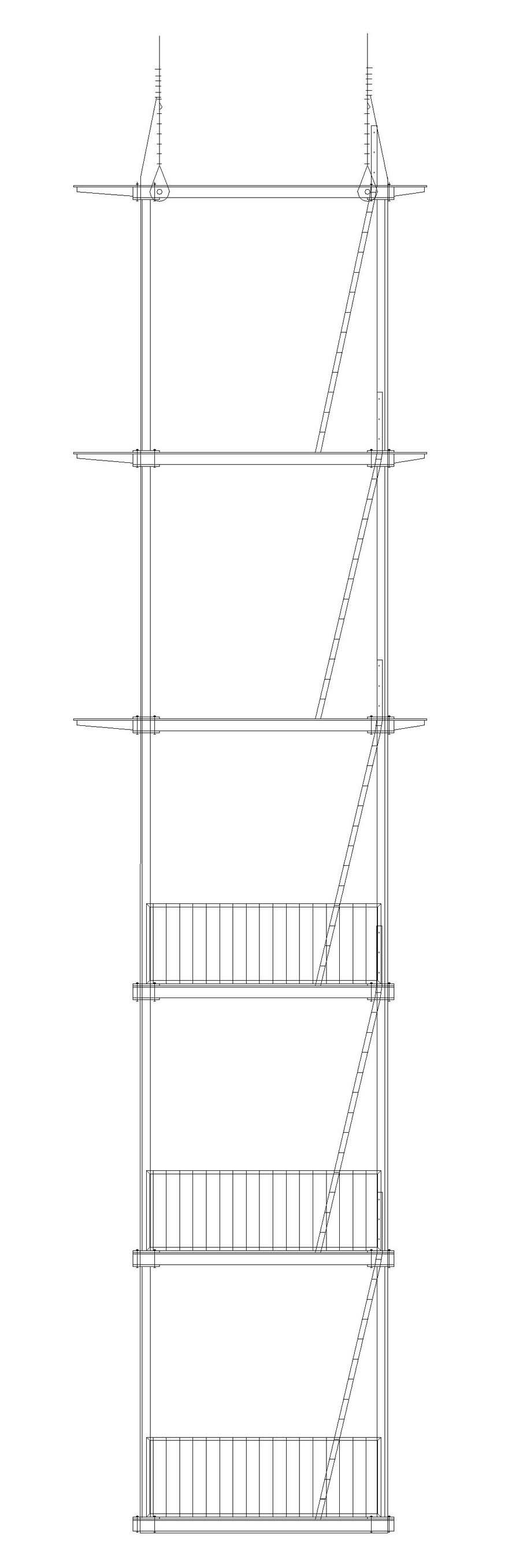

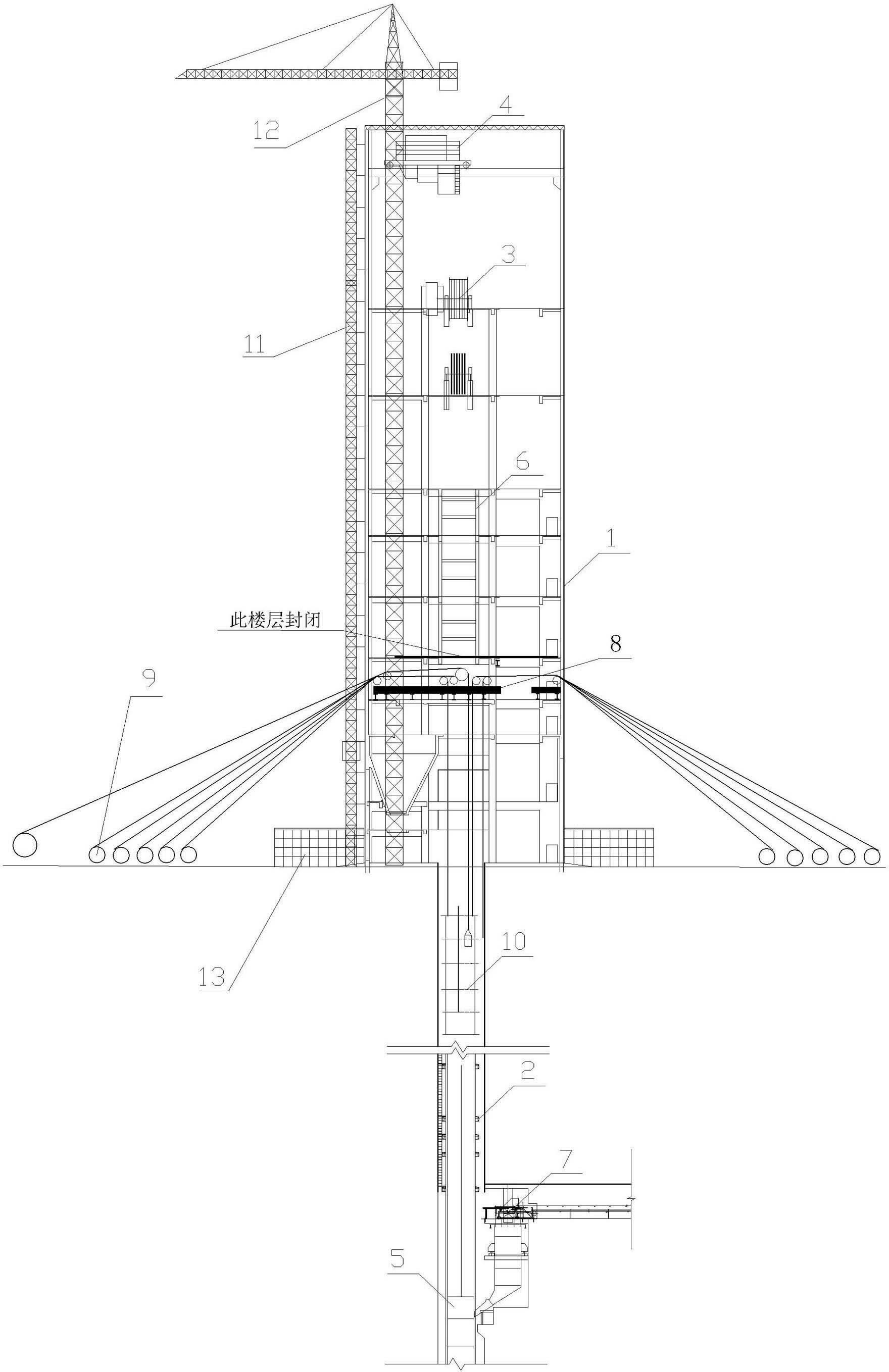

[0020] Such as figure 1 As shown, the rapid construction method of the well tower hoisting system includes seven unit projects of the well tower 1, the shaft equipment 2, the hoist 3, the crane 4, the hoisting facility 5, the casing frame 6, and the loading and unloading equipment 7. The well tower 1 unit project includes the well tower pile foundation, foundation, main body, and decoration; the well tower is constructed by sliding form technology or large formwork technology; The wellbore equipment 2 includes the shaft inner tank, the tank beam, the ladder room, cables, pipelines, and lower equipment; the shaft equipment adopts the arrangement of the sky wheel platform 8 in the well tower, and the six-layer suspension pan 10 is suspended from the temporary lifting facility 9 Down to the previous forming method construction. Crane 4 is a hoisting machine used for hoisting hoists and equipment in the well tower; the crane is hoisted to the crane track by means of a crane or by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com