Ejection-period setting method for sub-nozzles in air jet loom

A technology of air jetting and jetting period, applied in looms, textiles, textiles and papermaking, etc., can solve the problem of not being able to reduce the jetting period of the sub-nozzle group, reducing the amount of air jetting, etc., and achieve the effect of effective setting and easy setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

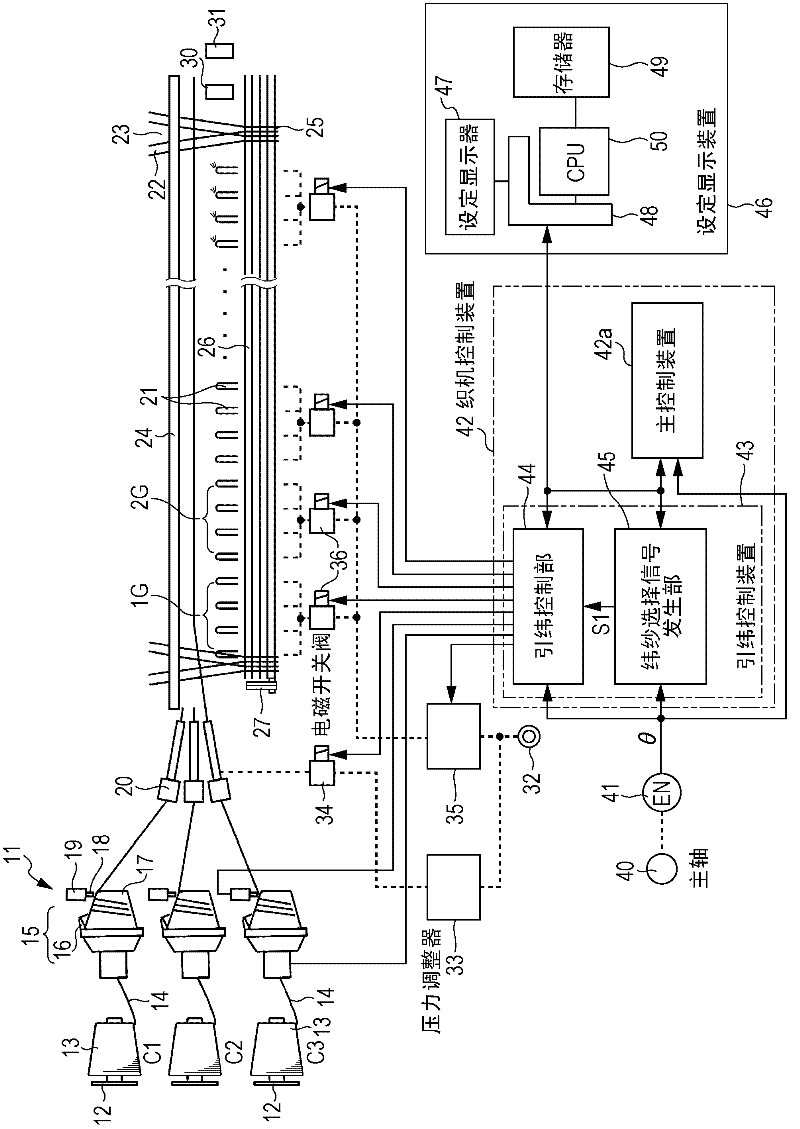

[0054] figure 1 As an example of an air jet loom to which the present invention is applied, a main part of a loom having a multi-color weft insertion device is shown. exist figure 1 Although only 3 weft insertion series are shown in , it is actually a 6-color weft insertion device with 6 weft insertion series. Hereinafter, description will be made based on this premise. In addition, this six-color weft insertion device corresponds to the multi-color weft insertion device of the present invention. The "weft insertion series" mentioned here refers to the group to which a plurality of weft insertion-related devices (length measuring and weft storage device 15, main nozzle 20, sub-nozzle 21, etc.) . But the sub-nozzle 21 is common to all weft insertion series.

[0055] exist figure 1 In the weft insertion device 11, the weft yarns 14 of colors C1, C2, C3... are drawn from the yarn supply body 13 supported by the yarn supply body frame 12, and are introduced into the yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com