Cotton/nylon blended infrared-proof camouflage fabric and printing and dyeing process thereof

A technology of infrared and blended yarns, which is applied in textiles, fabrics, textiles and papermaking, etc., can solve the problems of seldom research work, strength, infrared reflection coefficient and color fastness, etc., and achieve good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with embodiment.

[0049] 1. Fabric Design

[0050] In order to ensure the functionality of the fabric, the warp and weft yarns of the fabric are all made of 14 s Cotton-nylon blended yarn, the blending ratio is 50:50, the warp density of the fabric is 80 threads / in, the weft density is 53 threads / in, and the width is 161.4cm.

[0051] 2. Key points of process technology and key solutions

[0052] 1. Dyeing and finishing process:

[0053] Seaming, presetting, singeing, alkali steaming, oxygen bleaching, mercerizing, dyeing, printing, soft tentering, preshrinking, finished products.

[0054] 2. Pre-type test

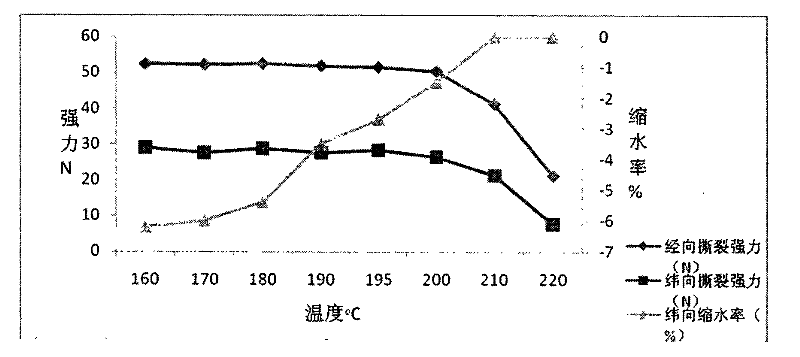

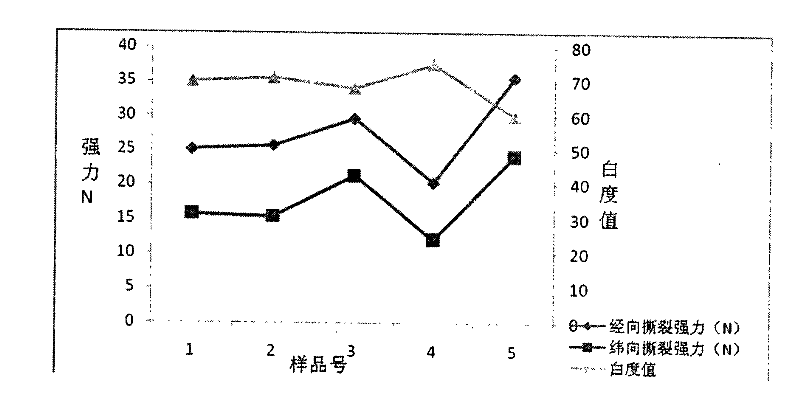

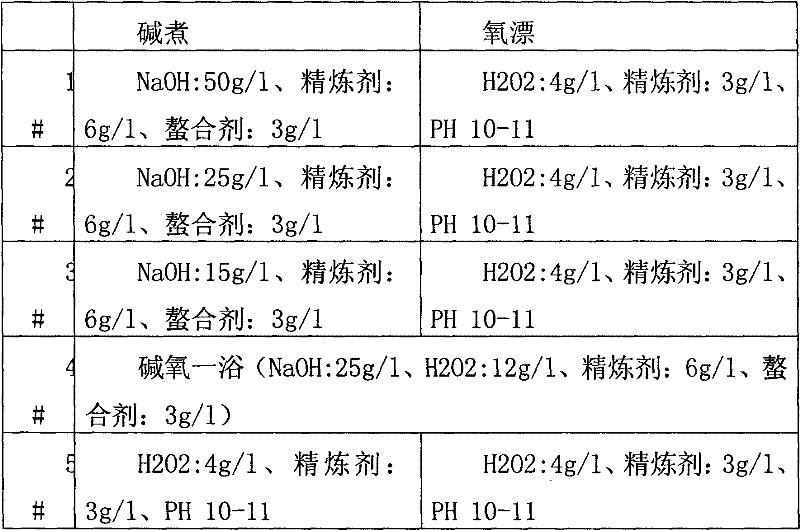

[0055] In order to ensure the shrinkage stability of the cotton nylon fabric and minimize the loss of strength, a pre-setting test is carried out.

[0056] Table 1 Data table of warp and weft strength and shrinkage of cotton nylon fabrics with temperature resistance

[0057] tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com