Nylon 66 anti-infrared fabric and preparation method thereof

A technology of nylon and anti-migration agent, which is applied in dyeing method, liquid-repellent fiber, fiber treatment, etc. It can solve the problems of multi-functional compounding and mutual conflict reduction, poor color consistency of fabrics, and unstable infrared reflectivity. Achieve good coloring effect, short process, improve functional durability and wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of nylon 66 anti-infrared fabric, the preparation method comprises the following steps:

[0031] (1) (Nylon 66 1000D*1000D 63″ plain weave Dahua) seam the original fabric, and then use the method of double dipping and rolling to soak the scouring and bleaching working solution to obtain the scouring and bleaching fabric; the temperature of the track is 95°C, and the stacking time is 60 minutes. The vehicle speed is 65m / min, and the liquid carrying rate is 88%. The scouring and bleaching working solution includes the following components: scouring agent HB101 2g / L, sodium hydroxide 5g / L and hydrogen peroxide 6g / L;

[0032] (2) Put the scouring and bleaching fabric obtained in step (1) into a tenter at 210°C, at a speed of 90m / min, at a fall temperature of less than 40°C, with a fall width of 158cm, and then roll until there are no crepe marks. shaped fabric;

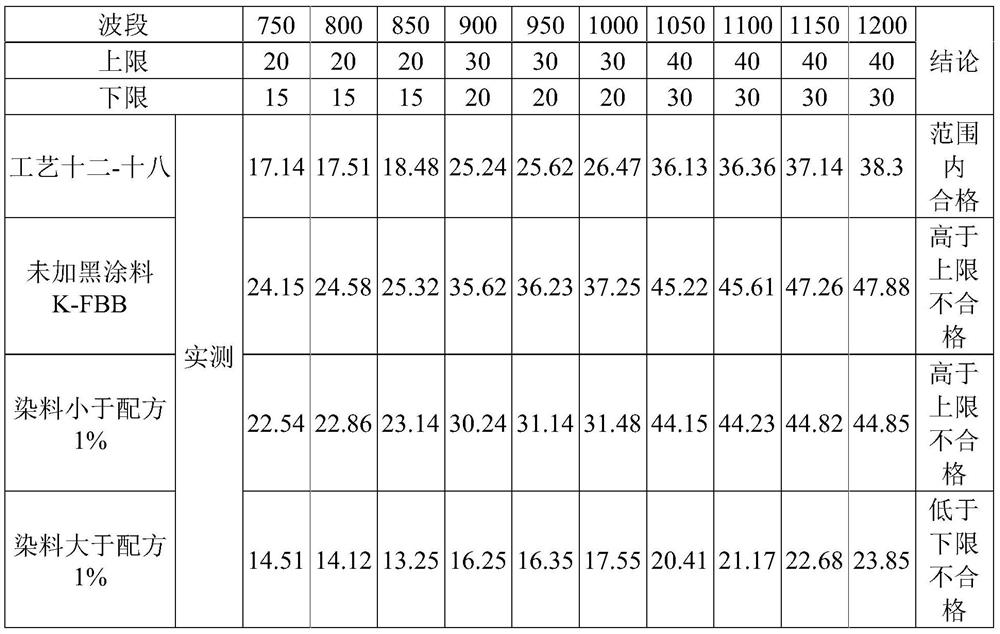

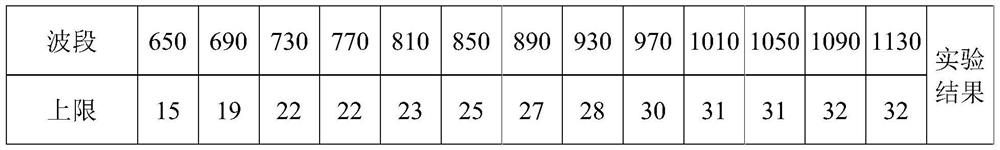

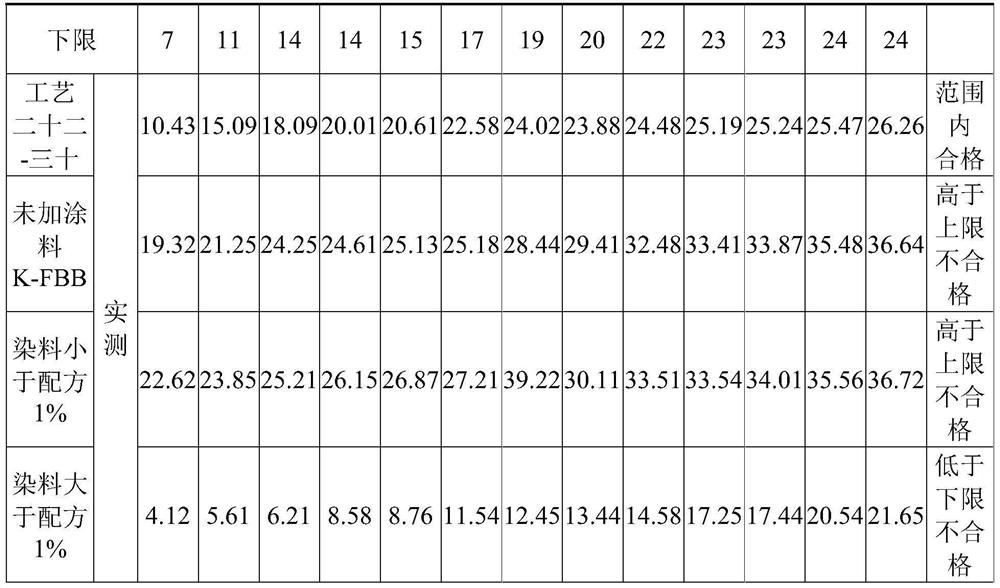

[0033] (3) Pad the pad dyeing liquid with the shaped fabric obtained in step (2), at a speed of 40 ± 5m / ...

Embodiment 2

[0043] A kind of nylon 66 anti-infrared fabric, the preparation method comprises the following steps:

[0044] (1) (Nylon 66 160D*160D plain weave) raw fabric seam head, and then use two dipping and two rolling methods to soak and roll the scouring and bleaching working solution to obtain the scouring and bleaching fabric; the track temperature is 98°C, the stacking time is 65min, and the speed is 68m / min , the liquid carrying rate is 89%; the scouring and bleaching working solution includes the following components: scouring agent HB101 2g / L, sodium hydroxide 5g / L and hydrogen peroxide 6g / L;

[0045] (2) Put the scouring and bleaching fabric obtained in step (1) into a tenter at 210°C, at a speed of 90m / min, at a fall temperature of less than 40°C, with a fall width of 158cm, and then roll until there are no crepe marks. shaped fabric;

[0046] (3) padding the pad dyeing solution of the shaped fabric obtained in step (2), at a speed of 40 ± 5m / min, drying to obtain dyed fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com