Diversified fiber yarn production method by rotor spinning

A production method, rotor spinning technology, applied in the field of rotor spinning diversified fiber yarn production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

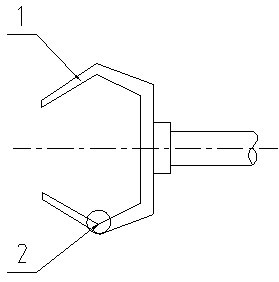

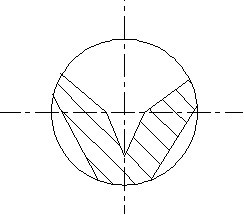

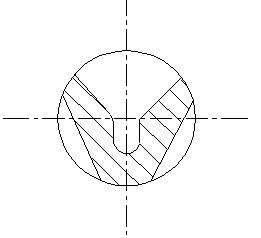

[0019] The invention relates to a method for producing multi-fiber yarns by rotor spinning, which comprises the following process: loose fiber dyeing → wool blending process → carding process → drawing frame → rotor spinning process → yarn doubling process → two-for-one twisting process, In the rotor spinning process, the fiber sliver is transported to the opening roller through the feeding mechanism, and under the action of the card clothing on the opening roller, the fiber sliver is combed into a single-fiber-like fiber flow again, and the single-fiber flow is Under the action of centrifugal force and negative pressure air, the comb roller separates from the pin teeth of the opening roller and enters the spinning cup under the action of negative pressure air. The spinning cup is a high-speed rotating part. After the single fiber flow enters the spinning cup , enter the coagulation groove under the action of its centrifugal force, so that the single fiber gathers again and for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com