Preparation method for perovskite lead titanate single-crystal nanometer sheet

A single crystal nano, lead titanate technology, applied in the direction of single crystal growth, nanotechnology, single crystal growth, etc., can solve the problem that there are no reports and patents of perovskite structure lead titanate single crystal nanosheets, and achieve easy The effect of mass production, simple process and easy control

Active Publication Date: 2012-07-04

ZHEJIANG UNIV

View PDF1 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

So far, there are almost no large-scale preparations of single ferroelectric single crystal nanosheets by chemical methods, and there are no reports and patents on perovskite structure lead titanate single crystal nanosheets.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

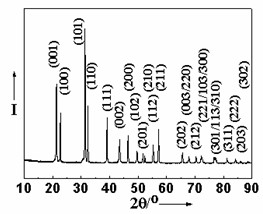

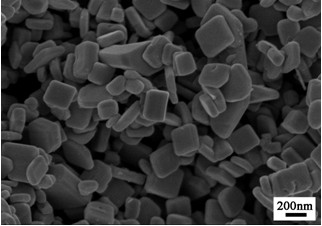

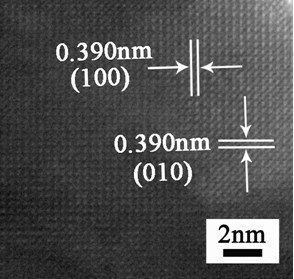

The invention relates to a preparation method for a perovskite lead titanate single-crystal nanometer sheet. A hydro-thermal reaction method is adopted according to the preparation method. The preparation method comprises the following steps: taking titanium dioxide as a raw material; taking a potassium hydroxide aqueous solution as a hydro-thermal medium and dropwise adding a lead nitrate aqueous solution; and stirring, and then performing thermal treatment at high temperature, thereby obtaining the perovskite lead titanate single-crystal nanometer sheet with a two-dimensional laminated structure. The technical process of the preparation method has the advantages of simpleness, easiness in control, zero pollution, low cost and easiness in mass production. The prepared perovskite lead titanate single-crystal nanometer sheet with the two-dimensional laminated structure is high in purity and excellent in dispersibility.

Description

technical field [0001] The invention relates to a method for preparing perovskite lead titanate single crystal nanosheets, belonging to the field of inorganic non-metallic materials. Background technique [0002] Lead titanate (PbTiO 3 ) is a typical ferroelectric oxide with a perovskite structure, which has a simple structure and excellent ferroelectric, piezoelectric, and dielectric properties. Lead titanate has been widely used in the preparation of microelectronic devices such as non-volatile ferroelectric memory, piezoelectric sensor, pyroelectric sensor and high dielectric capacitor. As the miniaturization requirements of electronic devices continue to increase, two-dimensional individual ferroelectric single crystal materials have attracted more and more attention. On the one hand, experiments confirmed that ultrathin single-crystal BaTiO 3 have reduced the thickness of single-crystal capacitors to 65nm, on the other hand, theoretical studies predict ferroelectric ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C30B29/32C30B7/10C30B29/64B82Y40/00

Inventor 任召辉钞春英韩高荣徐刚沈鸽

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com