Double-plate or double-side film coating system

A double-sided coating and coating chamber technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of low production efficiency, reduced glass cleaning results, and high equipment maintenance costs in the glass coating production line. Achieve the effect of saving human resource loss, facilitating equipment maintenance, and long maintenance intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

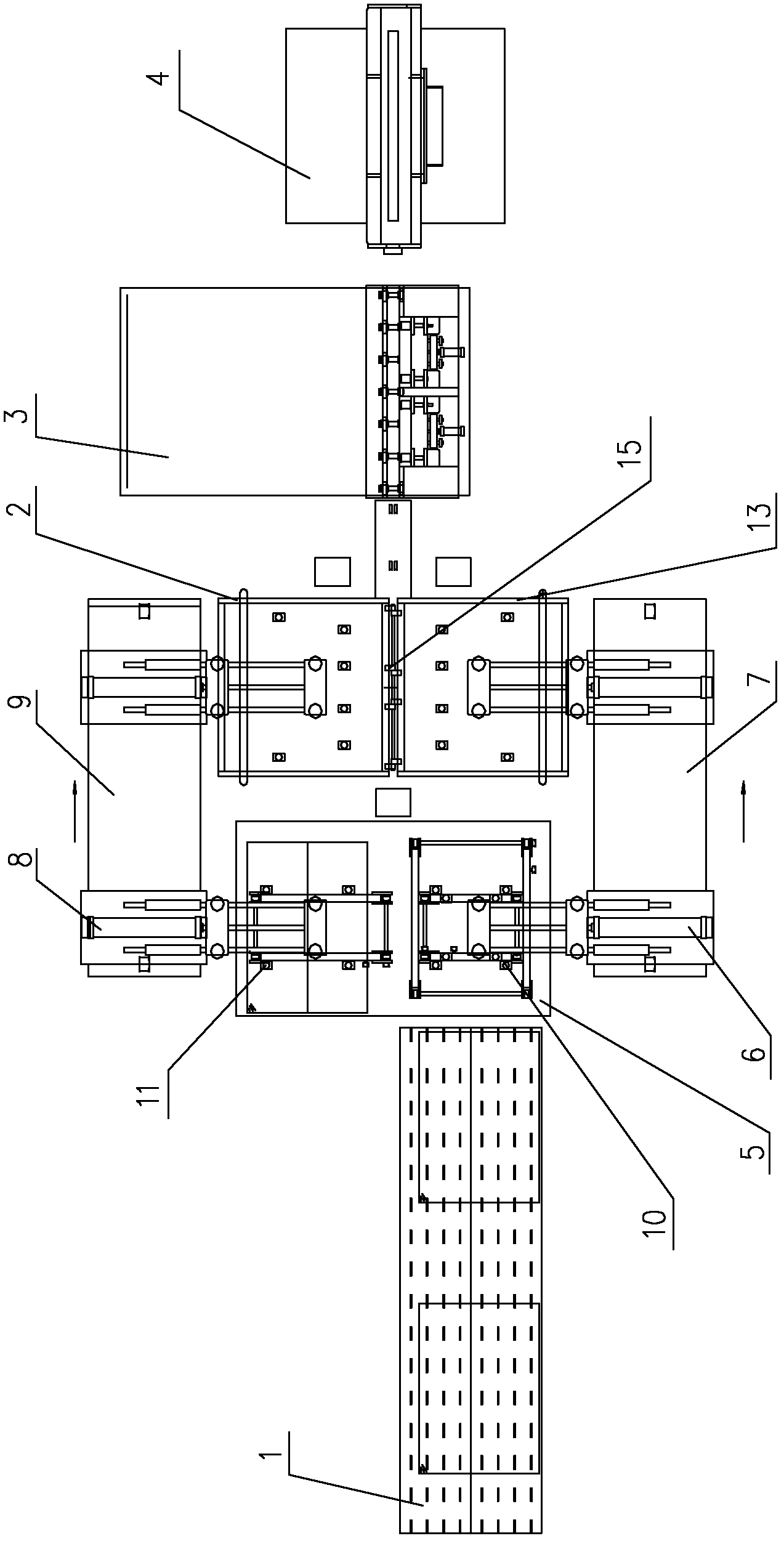

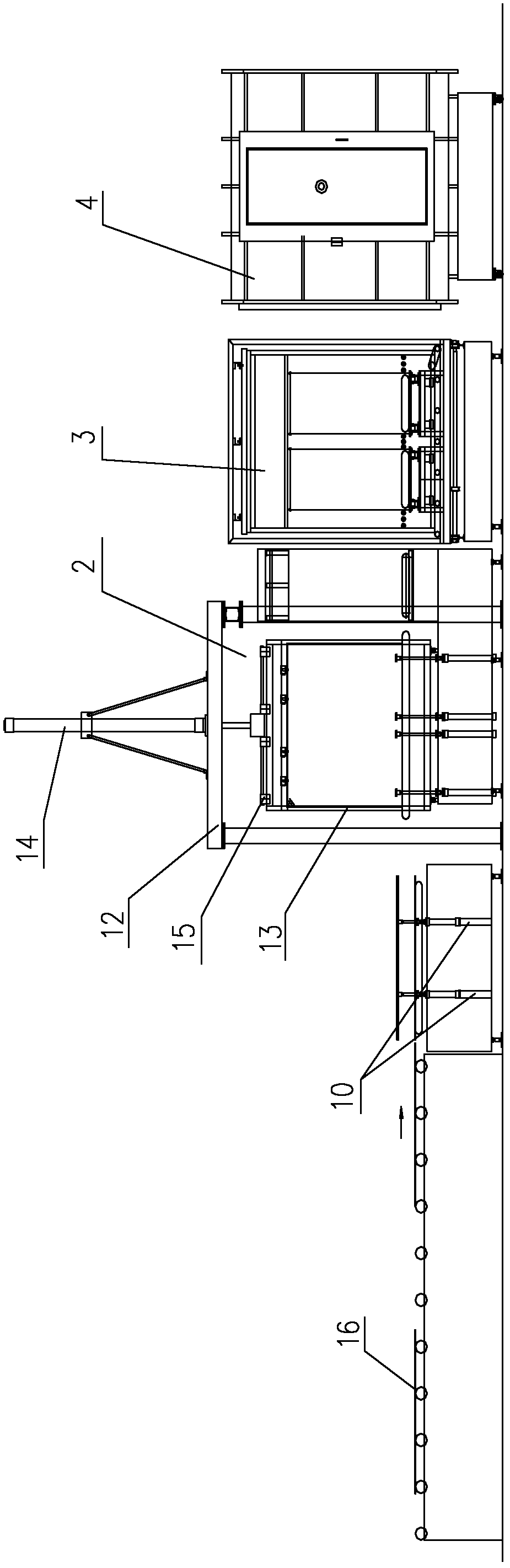

[0040] In this embodiment, a double-chip or double-sided coating system has a structure such as Figure 5 or Figure 6 As shown, it includes a plurality of vacuum chambers arranged in a straight line, and a through hole is provided between any adjacent two vacuum chambers. The first vacuum chamber is the film feeding chamber 4, and the last vacuum chamber is the film output chamber 23. At least one coating chamber 20 is arranged between the film feeding chamber 4 and the film discharging chamber 23; the chamber walls of the coating chambers located on the left and right sides of the workpiece conveying direction are provided with chamber doors, and magnetron sputtering targets 32 are installed on each chamber door.

[0041] A film feed frame 3 is provided outside the film feed port of the film feed chamber 4 , and a film discharge rack 24 is provided outside the film discharge port of the film discharge chamber 13 .

[0042] A plurality of vacuum chambers also includes a pre-...

Embodiment 2

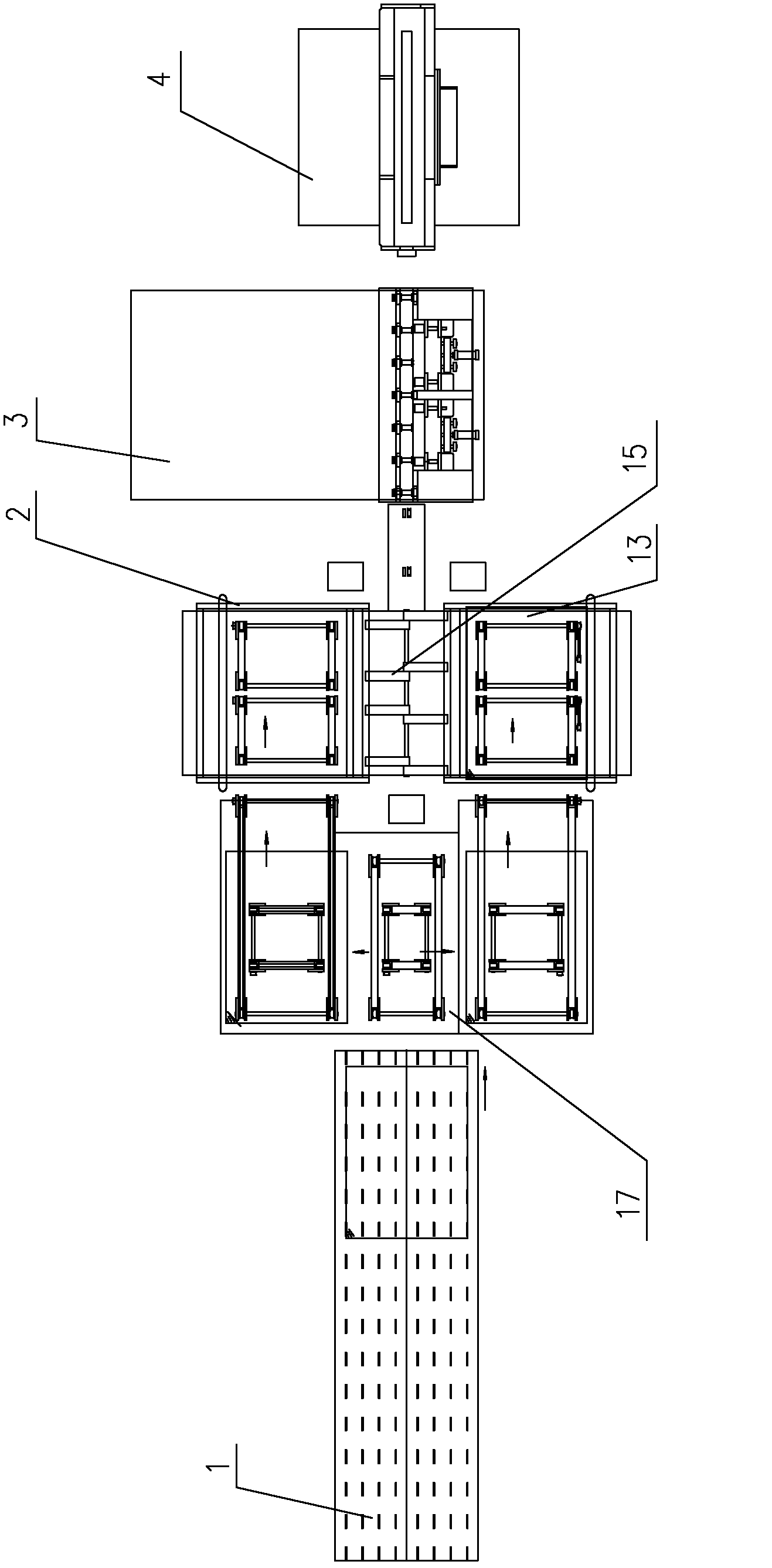

[0056] A kind of double-sheet or double-sided coating system of this embodiment, compared with embodiment 1, its difference lies in the structural form of its double-sheet conveying mechanism, as image 3 or Figure 4 As shown, the double-sheet transmission mechanism includes a reciprocating conveyor belt 17 that moves back and forth on the side of the hinge frame. The reciprocating conveyor belt 17 is arranged at the output end of the washing machine conveyor table 1. hinge frame 2;

[0057] There are 3 workpiece positions on the reciprocating conveyor belt 17, including the middle workpiece position and 2 side workpiece positions. The middle workpiece position is correspondingly set at the output end of the conveyor table of the washing machine, and the 2 side workpiece positions are respectively arranged on both sides of the middle workpiece position. .

[0058]When the double-piece workpiece input device is used, the working process of the double-piece conveying mechanis...

Embodiment 3

[0060] This embodiment is a double-sheet or double-sided coating system. Compared with Embodiment 1, its difference lies in the structure of each vacuum lock, the first vacuum lock, the second vacuum lock, the third vacuum lock, and the fourth vacuum lock , the fifth vacuum lock, the sixth vacuum lock and the seventh vacuum lock have the same structure, such as Figure 8 As shown, it includes a cylinder 33, a valve body 34, a valve core 36 and a lower cleaning cover plate 37. The valve body is a hollow cuboid structure. The left and right side walls of the valve body are fixedly connected with the vacuum chambers on both sides respectively. There are valve body through holes 35 respectively on the left and right side walls of the valve body, the valve body through holes communicate with the through holes in the vacuum chambers on both sides of the valve body, the valve core is located inside the valve body, and the end of the cylinder passes through the top of the valve body an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com