Unsaturated polyester modified polyurethane high-gloss top-coat paint and preparation method and using method thereof

A polyester modified and unsaturated technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as troublesome, PU clear topcoats that cannot be cleared by unsaturated polyester, and achieve strong adhesion, The effect of good fullness and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Preparation of unsaturated polyester modified polyurethane high-gloss clear topcoat comprises the following steps (see Table 3 for each component and weight ratio):

[0068] Step 1: Prepare unsaturated polyester main paint components (take each component according to the weight listed in "PE Example 1" in Table 1):

[0069] Add unsaturated polyester topcoat resin, defoamer, and wetting agent to the container in sequence, disperse for 3-5 minutes at 500RPM until uniform; add leveling agent A, leveling agent B, styrene and butyl acetate in sequence, 500RPM Disperse for 5 minutes until uniform, and filter through 200 mesh to obtain the unsaturated polyester main paint component of this embodiment.

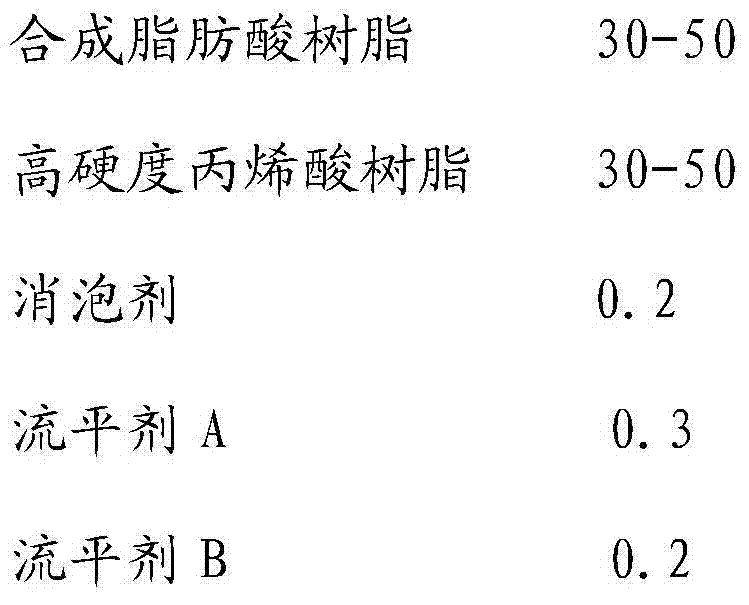

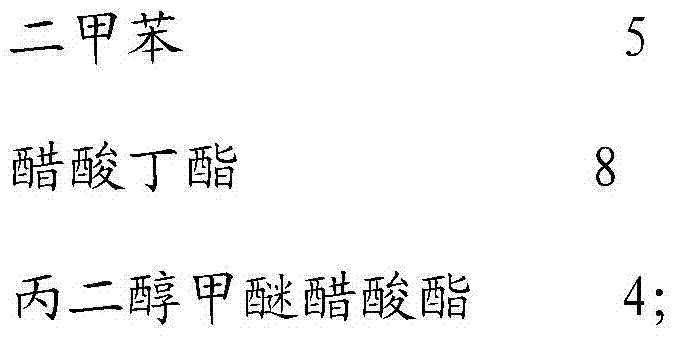

[0070] Step 2: Prepare the polyurethane main paint components (take each component according to the weight listed in "PU Example 1" in Table 2):

[0071] Put synthetic fatty acid resin and high hardness acrylic resin into the container, disperse at 500RPM for 3-5 minutes; add ...

Embodiment 2

[0081] The difference from Example 1 is: the preparation of unsaturated polyester main paint components in step one is to get each component according to the weight listed in "PE Example 1" in Table 1; the preparation of polyurethane main paint components in step two is according to the weight listed in Table 1 The weight listed in "PU Example 2" in the second is taken from each component.

[0082] The performance test results of the finished product of unsaturated polyester modified polyurethane high-gloss clear topcoat are shown in the corresponding data of Example 2 in Table 4.

Embodiment 3

[0084] The difference from Example 1 is: the preparation of unsaturated polyester main paint components in step one is to get each component according to the weight listed in "PE Example 1" in Table 1; the preparation of polyurethane main paint components in step two is according to the weight listed in Table 1 The weight listed in "PU Example 3" in the second is taken from each component.

[0085] The performance test results of the finished product of unsaturated polyester modified polyurethane high-gloss clear topcoat are shown in the corresponding data of Example 3 in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com