Renewable bundled and crosslinked rubber material

A cross-linked rubber and rubber technology, which is applied in the field of bundled and cross-linked rubber materials, can solve problems such as weak force, limited rubber type, low cross-linking efficiency, and restrictions on the application of coordination cross-linked rubber, and achieve recycling The effect of reuse, simple formula and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

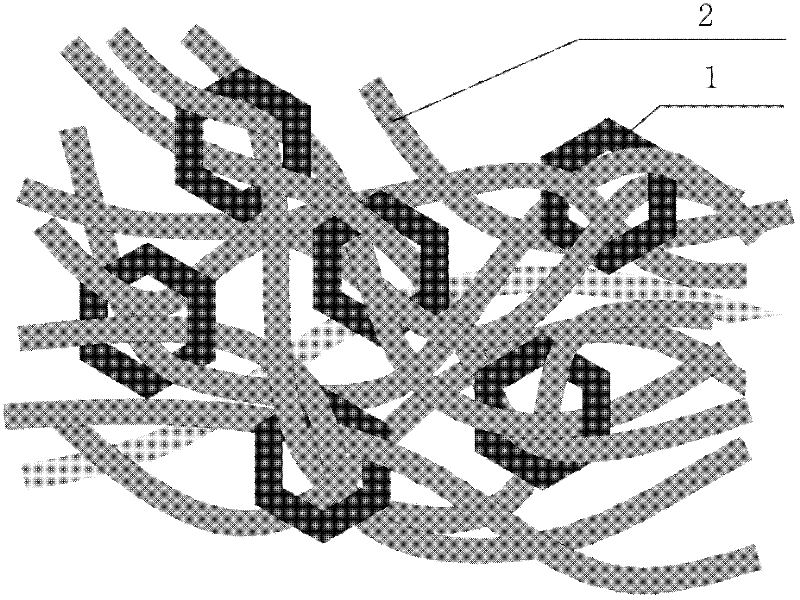

Image

Examples

Embodiment 1

[0023] 100 parts of butadiene rubber, 18 parts of succinic acid, 9 parts of calcium oxide, mixed evenly on a double-roll mill or internal mixer at 45°C, and then hot-pressed on a flat vulcanizer at 200°C, 10Mpa for 30 minutes, A bundled cross-linked rubber material can be obtained. The bundled cross-linked rubber material has a tensile strength of 6MPa, a fracture growth rate of 550%, and a hardness (Shore A) of 45. After being placed at 150°C for 48 hours, the tensile strength retention rate of the material is 95%.

Embodiment 2

[0025] 100 parts of butadiene rubber, 18 parts of succinic acid, 9 parts of calcium oxide, and 50 parts of carbon black, mixed evenly on a double-roll mill or internal mixer at 45°C, and then heated on a flat vulcanizer at 200°C and 10Mpa After hot pressing for 30 minutes, a bundled cross-linked rubber material can be obtained. The bundled cross-linked rubber material has a tensile strength of 15MPa, a fracture growth rate of 400%, and a hardness (Shore A) of 60. After being placed at 150°C for 48 hours, the tensile strength retention rate of the material is 95%.

Embodiment 3

[0027] 100 parts of butadiene rubber, 30 parts of maleic acid, 15 parts of calcium oxide, 50 parts of carbon black, mixed evenly on a double-roll mill or internal mixer at 45°C, and then heated on a flat vulcanizer at 180°C and 10Mpa After hot pressing for 15 minutes, a bundled cross-linked rubber material can be obtained. The bundled cross-linked rubber material has a tensile strength of 30MPa, a fracture growth rate of 350%, and a hardness (Shore A) of 70. After being placed at 150°C for 48 hours, the tensile strength retention rate of the material is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com