Method for continuously separating sialic acid

A technology of sialic acid and continuous ions, which is applied in the direction of chemical instruments and methods, sugar compounds with non-glycosyl groups, sugar derivatives, etc. It can solve the problems of unsuitable industrial production, poor separation and purification effect, and only intermittent operation, etc. problems, to achieve the effect of low operating cost, simple and easy separation and purification method, and increased concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

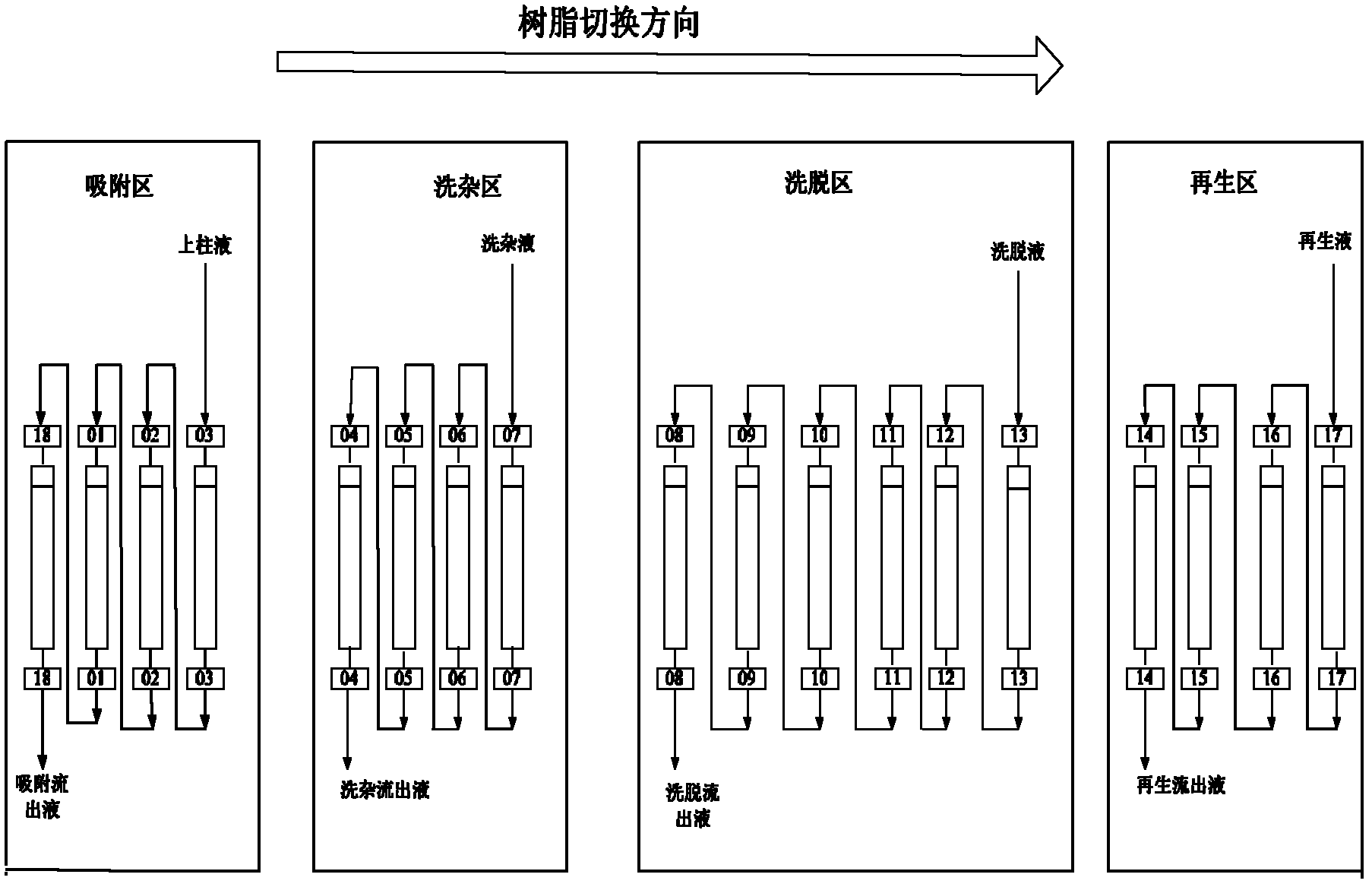

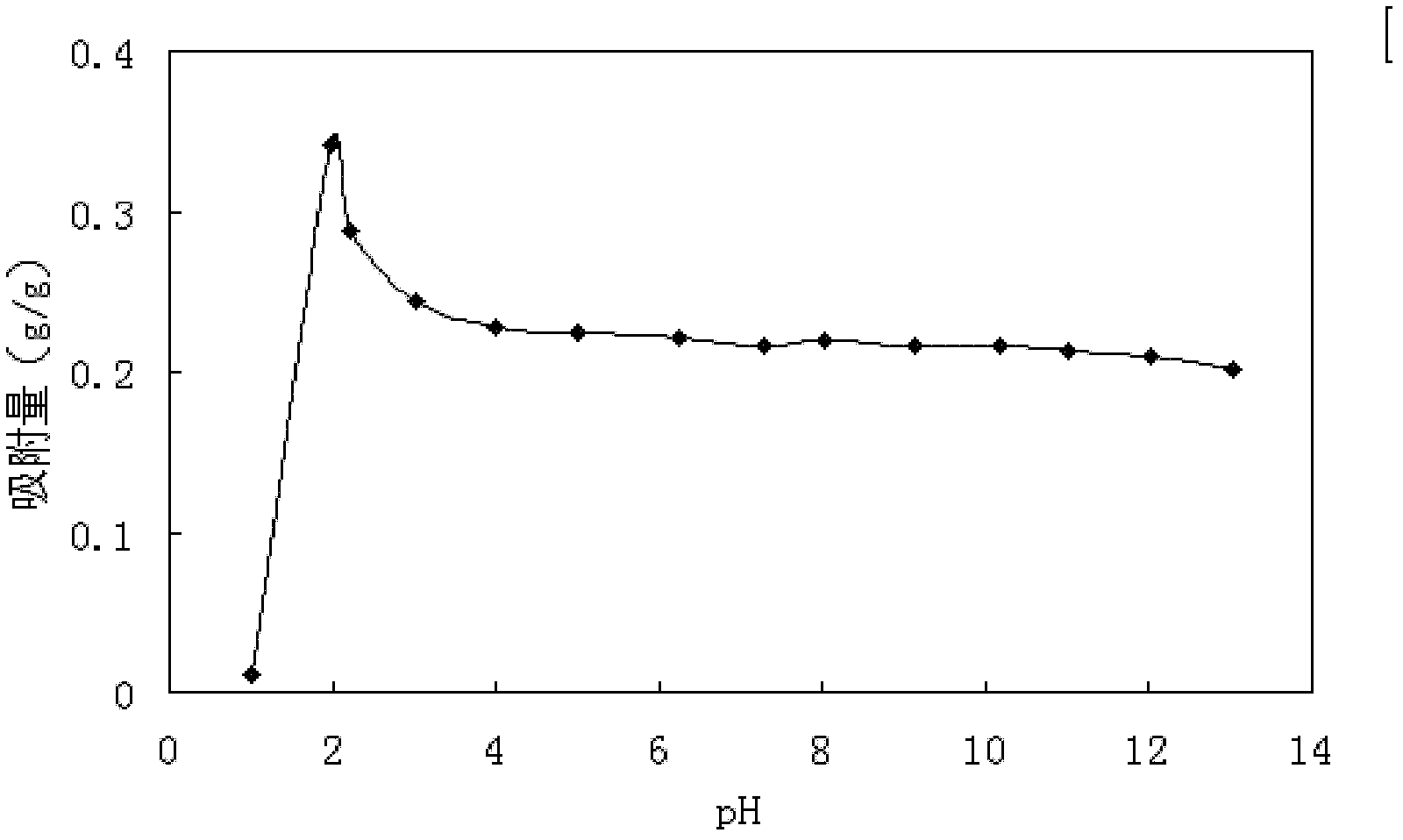

[0043] After the fermentation broth is filtered, most of the protein is removed through an ultrafiltration membrane with a molecular weight cut-off of 10,000 Daltons, and the supernatant is diluted to a concentration of sialic acid of about 5g / L, and then pumped into a continuous ion exchange machine filled with anion exchange resin. system. A continuous ion exchange system consisting of 12 anion exchange columns is adopted, with 3 columns in the adsorption area, 3 columns in the impurity washing area, 4 columns in the elution area, and 2 columns in the regeneration area. Each zone can be used in series to increase the concentration of the target product effluent. Each ion exchange column was loaded with 100 g of resin. The adsorption flow rate is 3ml / min, and the adsorption capacity is 0.341g / g wet resin; the washing solution is deionized water, and the flow rate is 3ml / min, and the washing is done until the effluent is free of impurities (use HPLC to determine the first pla...

Embodiment 2

[0045] After the fermentation broth is filtered, most of the protein is removed through an ultrafiltration membrane with a molecular weight cut-off of 30,000 Daltons, the supernatant is diluted to a concentration of sialic acid of about 10 g / L, and pumped into a continuous ion exchange machine filled with anion exchange resin. system. A continuous ion exchange system consisting of 14 anion exchange columns is adopted, 4 in the adsorption area, 3 in the impurity washing area, 4 in the elution area, and 3 in the regeneration area. Each zone can be connected in series to increase the concentration of the target product effluent. Each ion exchange column was packed with 400g resin. The adsorption flow rate is 15ml / min, and the adsorption capacity is 0.244g / g wet resin; the washing solution is deionized water, and the washing flow rate is 25ml / min, and the washing is performed until the effluent is free of impurities (use HPLC to determine the area of the washing area). The fir...

Embodiment 3

[0047] After the fermentation broth is filtered, most of the protein is removed through an ultrafiltration membrane with a molecular weight cut-off of 40,000 Daltons, and the supernatant is diluted to a concentration of sialic acid of about 15g / L, and then pumped into a continuous ion exchange machine filled with anion exchange resin. system. A continuous ion exchange system consisting of 14 anion exchange columns is adopted, 4 in the adsorption area, 3 in the impurity washing area, 4 in the elution area, and 3 in the regeneration area. Each zone can be connected in series to increase the concentration of the target product effluent. Each ion exchange column is filled with 1.2Kg resin. The adsorption flow rate is 60ml / min, and the adsorption capacity is 0.244g / g wet resin; the washing liquid is deionized water, and the washing flow rate is 50ml / min. An ion-exchange column has no impurity to flow out); The eluent is the sodium chloride solution of 0.8mol / L, and the elution fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com