Metal hydride hydrogen compression device with heat source and manufacture method thereof

A compression device and hydride technology, applied in the direction of hydrogen production, etc., can solve the problem of inability to provide an external heating source for a hydrogen compression device, and achieve the effects of simple structure, good safety and high heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

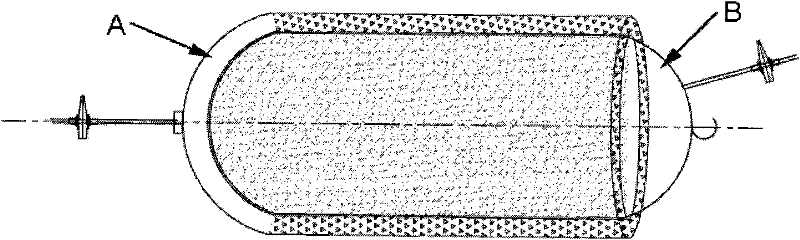

[0037] For metal hydride hydrogen compression part A, two seamless stainless steel cylinders with internal diameters of 55 cm and 72 cm are interposed, the thickness of the inner tube is 2 cm, and the thickness of the outer tube is 3 cm, and a stainless steel ring piece with a thickness of 4 cm is used to connect the two. The cylinders are welded together, and the other ends are respectively welded with spherical heads with a thickness of 2cm and 3cm. Open an air guide hole on the outer spherical head, weld a gas filter with a diameter of 13cm in the hole, the filter aperture is 3μm, weld a stainless steel transition part with an outer diameter of 6cm above the air guide hole, and weld an outer diameter of 6cm above the transition part. 3cm stainless steel air guide tube, and install a ball valve on the air guide tube. 1kg of Ti-Mn-based hydrogen storage alloy material Ti mixed with copper mesh is housed in the annular groove 0.9 Zr 0.1 mn 1.4 Cr 0.35 V 0.2 Fe 0.05 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com