Purification equipment for industrial sewage treatment

A technology for purifying equipment and industrial sewage, applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of purification efficiency, improving work efficiency and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

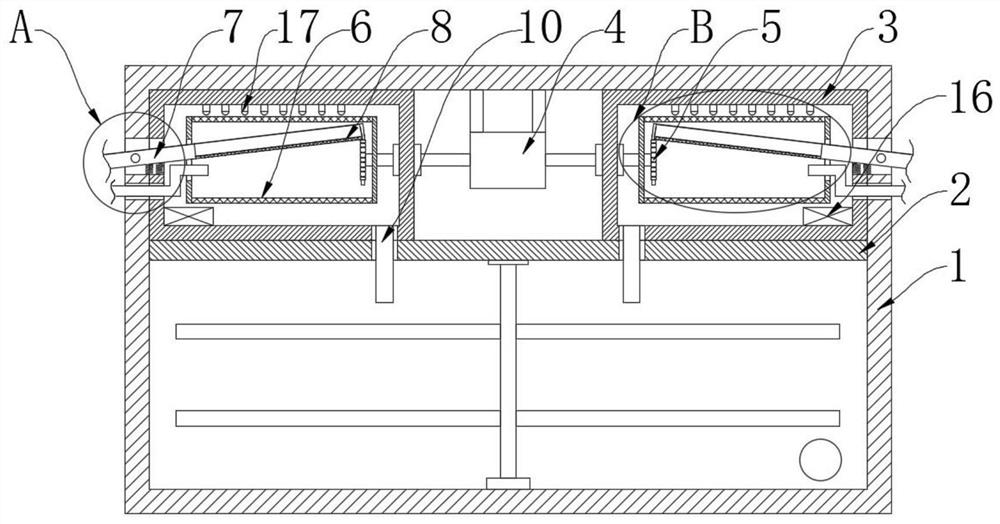

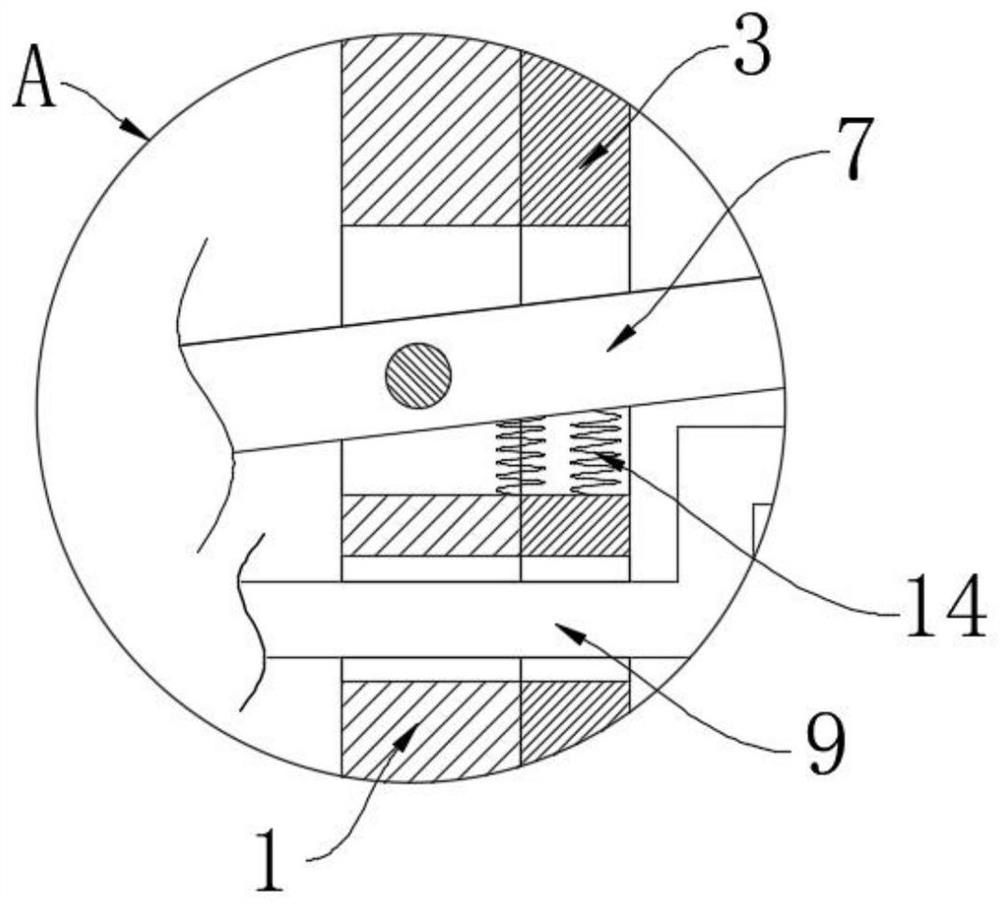

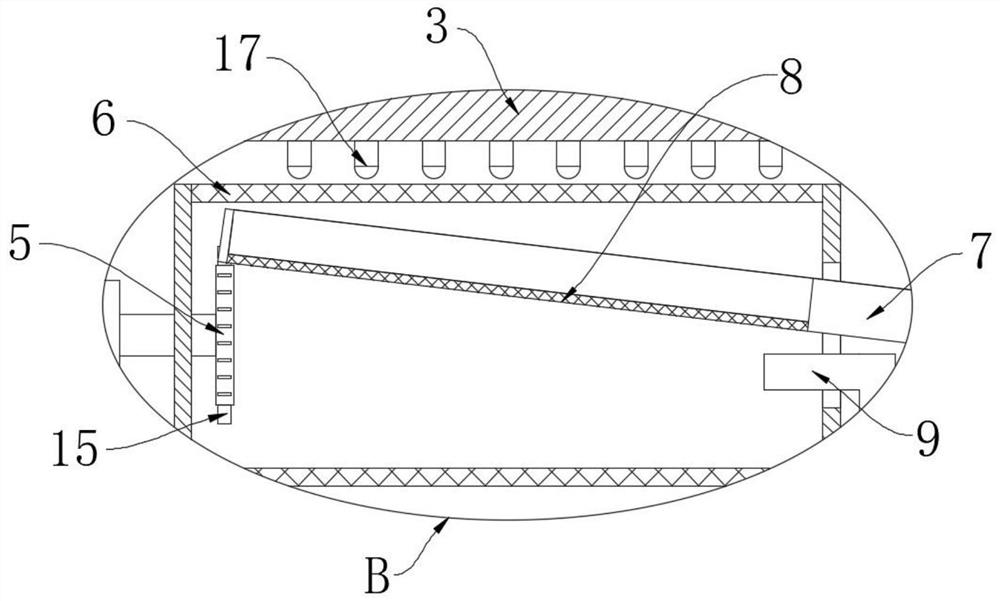

[0025] refer to Figure 1-4 , a purification equipment for industrial sewage treatment, comprising a treatment box 1, the inner wall of the treatment box 1 is fixedly installed with a mounting plate 2, the upper surface of the mounting plate 2 is symmetrically provided with two fixed cylinders 3, and the inner wall of the treatment box 1 is fixedly installed with Bidirectional motor 4, the output end of bidirectional motor 4 extends to the inside of fixed cylinder 3 and is fixedly installed with turntable 5, and the output end surface of bidirectional motor 4 inside fixed cylinder 3 is fixedly installed with filter screen cylinder 6, and the surface of filter screen cylinder 6 The mesh structure is an adsorption type mesh plate, the inner bottom wall of the fixed cylinder 3 is provided with a water pump 16, and the inner top wall of the fixed cylinder 3 is provided with several water spray heads 17 corresponding to the filter screen cylinder 6, and the water pump 16 The water ...

Embodiment 2

[0030] refer to Figure 5-6 , different from Embodiment 1, the inner bottom wall of the processing box 1 is rotatably connected with a stirring rod 11, the top of the stirring rod 11 extends to the upper surface of the mounting plate 2, the top of the stirring rod 11 and an output shaft of the bidirectional motor 4 Bevel gears 12 are fixedly installed on the surfaces, and the two bevel gears 12 mesh with each other, and several stirring rods 13 are arranged on the surface of the stirring rod 11 .

[0031] The inner top wall of the treatment box 1 is embedded with a flocculant injection box 18, the upper surface of the flocculant injection box 18 is provided with an adding pipe, and the lower surface of the flocculant injection box 18 is provided with two injection pipes 19, and the two injection pipes 19 The bottom ends extend to the insides of the two outlet pipes 10 respectively.

[0032] The upper surface of the mounting plate 2 is provided with a push-type air pump 20, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com