Multi-part moulding strip

A technology for baffle strips, accessories, used in vehicle components, sealing devices, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

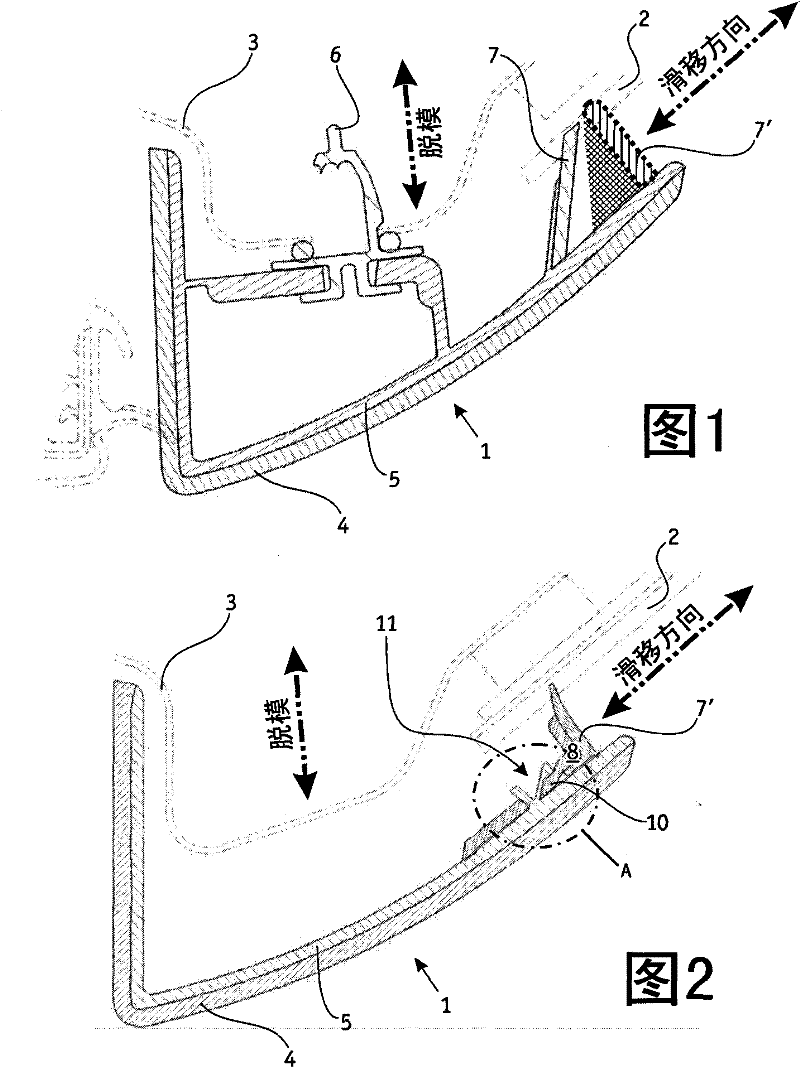

[0030] In order to clarify the present invention, in figure 1 A fender strip 1 which is not part of the invention is shown in . The apron strip is shown here by way of example as a cladding strip which covers the gap between the front windshield 2 and the body frame 3 of the motor vehicle.

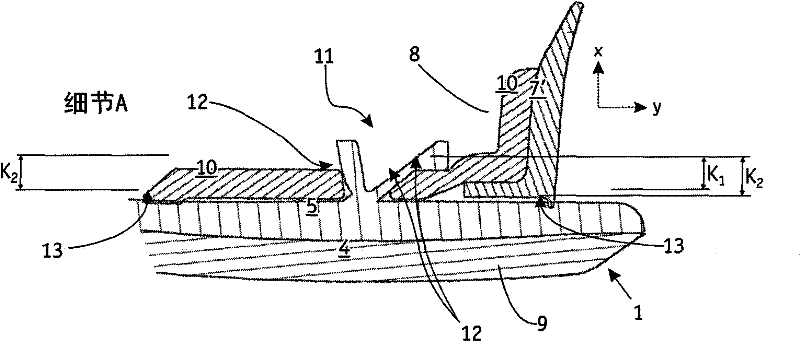

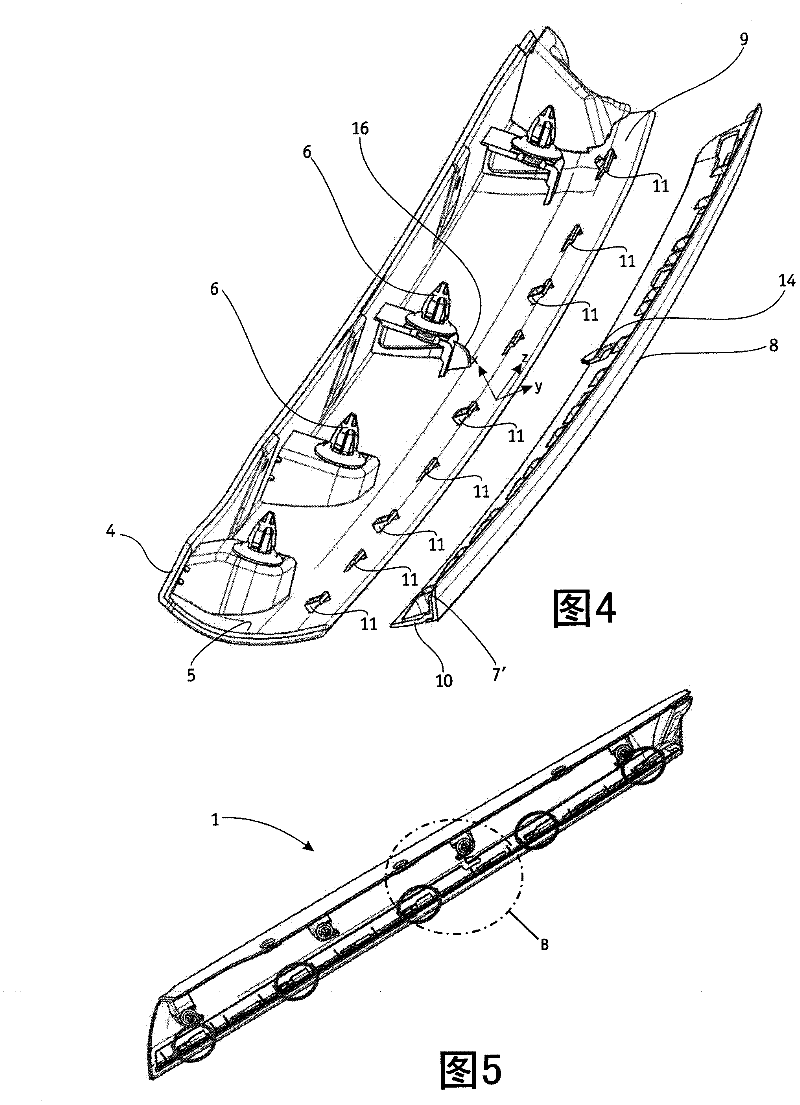

[0031] The strip 1 is produced from a total of three plastic components in a multi-component injection molding method. The brittle, impact-resistant and scratch-resistant first plastic forms a strip-shaped decorative part 4 or decorative layer 4 pointing outwards in the intended installed state on the vehicle. The decorative part 4 is injected from the outside onto a likewise strip-shaped carrier part 5 made of a second plastic, which, due to its ductile and fracture-resistant material properties, assumes functional tasks, such as receiving fastening elements 6 or elastically support the sealing element 7. A third plastic is injected onto the carrier part 5 in order to form the soft ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com