Method and tool system for manufacturing multi-component plastic molded part

A technology of plastic molds and components, applied in the field of manufacturing multi-component plastic molded components and tool systems, which can solve the problems of time loss and achieve the effect of controlling temperature distribution and avoiding thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention is not restricted to the above-described embodiments, which are presented as examples only and which can be modified in various ways within the scope of protection defined by the appended claims. The invention therefore also applies to different embodiments, in particular to different embodiments of a method for producing multi-component plastic molded parts and a tool system with an injection molding machine.

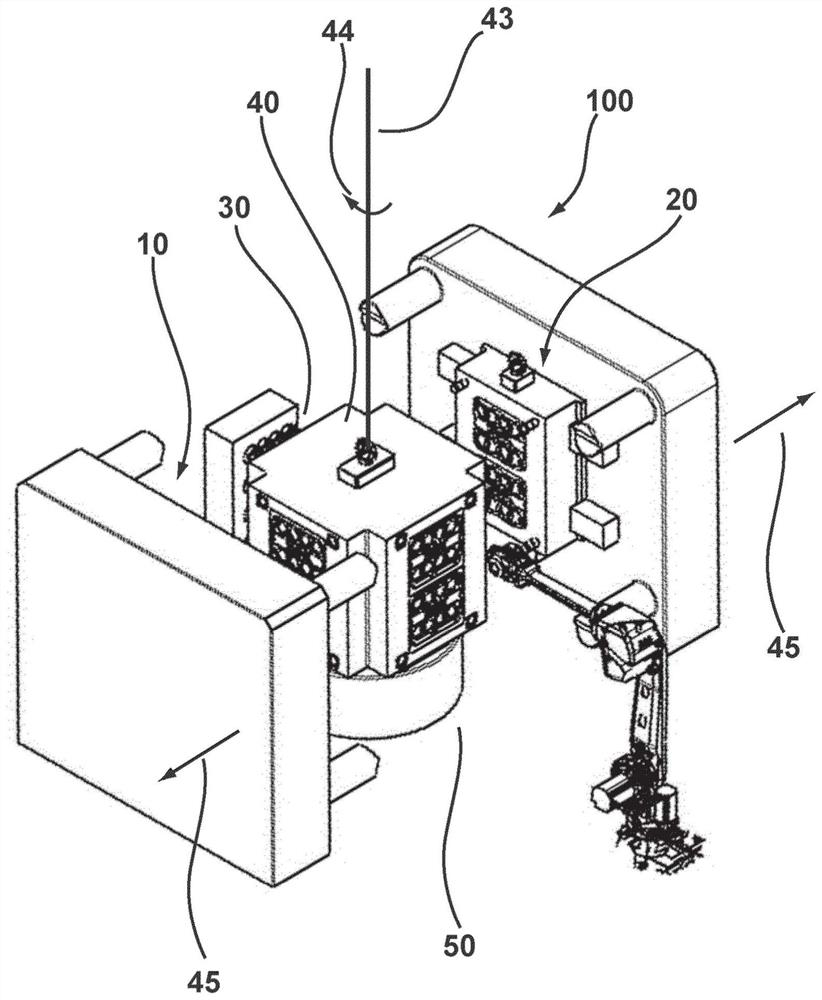

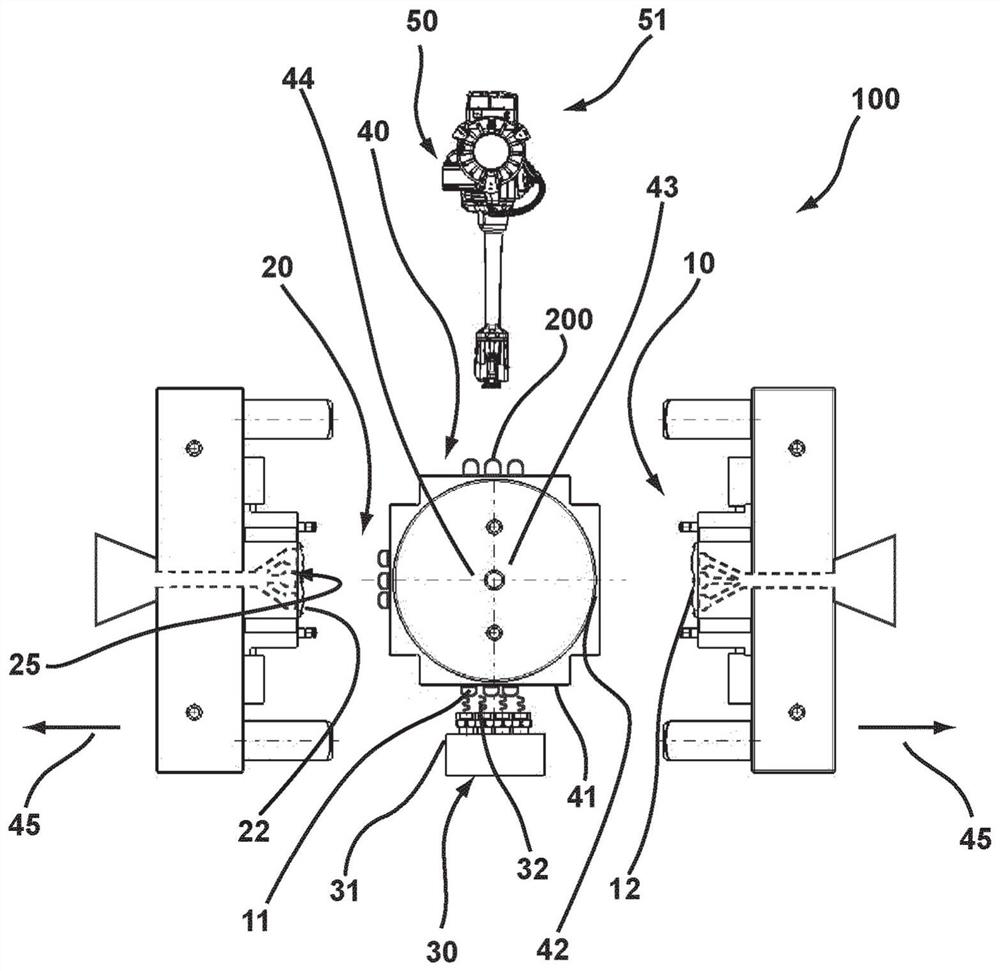

[0028] exist figure 1 and 2 A tooling system 100 with an injection molding machine including a first outer mold half 12 and a second outer mold half 22 and a rotating support block 40 is shown in FIG. The support block 40 is rotatable about an axis of rotation 43 and comprises four sides 41 each holding an inner mold half 42 . The injection molding machine is in an open position with the first outer mold half 12 and the second outer mold half 22 moving in spaced apart directions 45 . The bracket block 40 is positioned centrally between the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com