Liquid injector, and medical device

一种喷射装置、液体的技术,应用在印刷、脉冲持续时间/宽度调制、电气元件等方向,能够解决放大率变化、不能驱动波形信号生成驱动信号、不能稳定驱动波形信号等问题,达到实现紧凑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, in order to clarify the contents of the present invention described above, examples will be described in the following order.

[0038] A. Device structure:

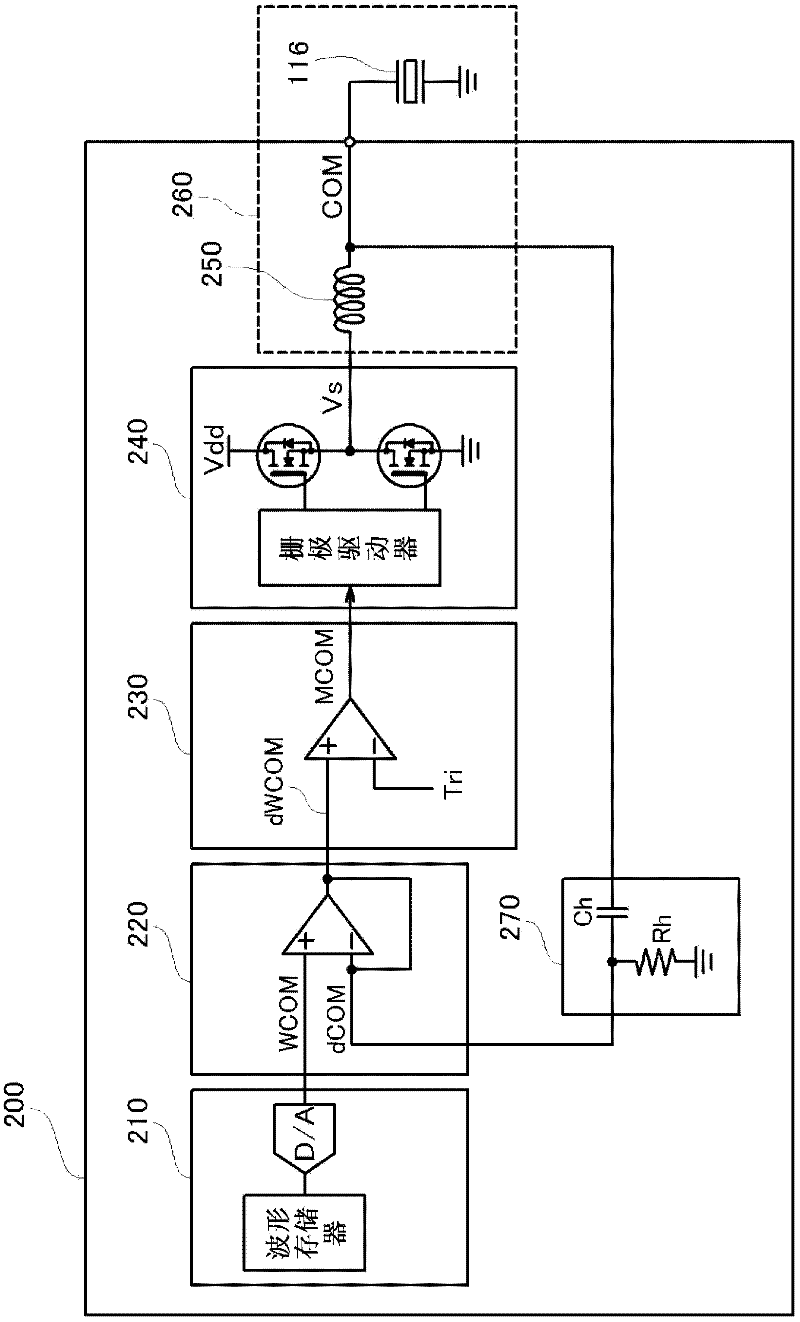

[0039] B. The circuit structure of the capacitive load drive circuit:

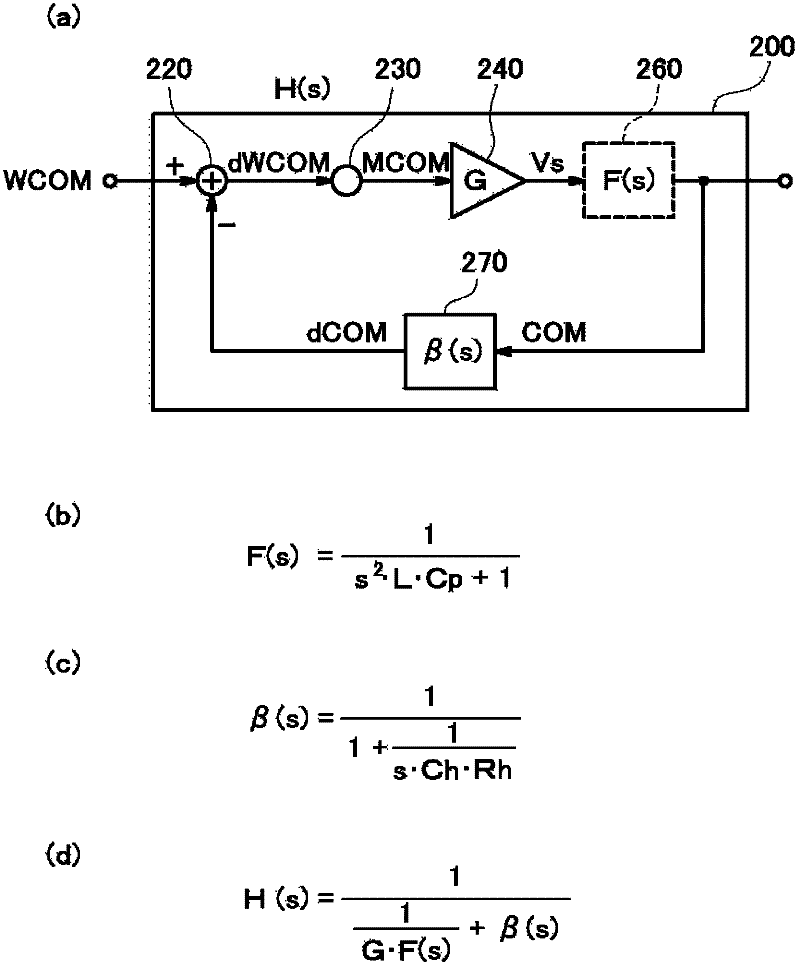

[0040] C. Action of capacitive load drive circuit:

[0041] D. Variations:

[0042] D-1. The first modified example:

[0043] D-2. Second modified example:

[0044] A. Device structure:

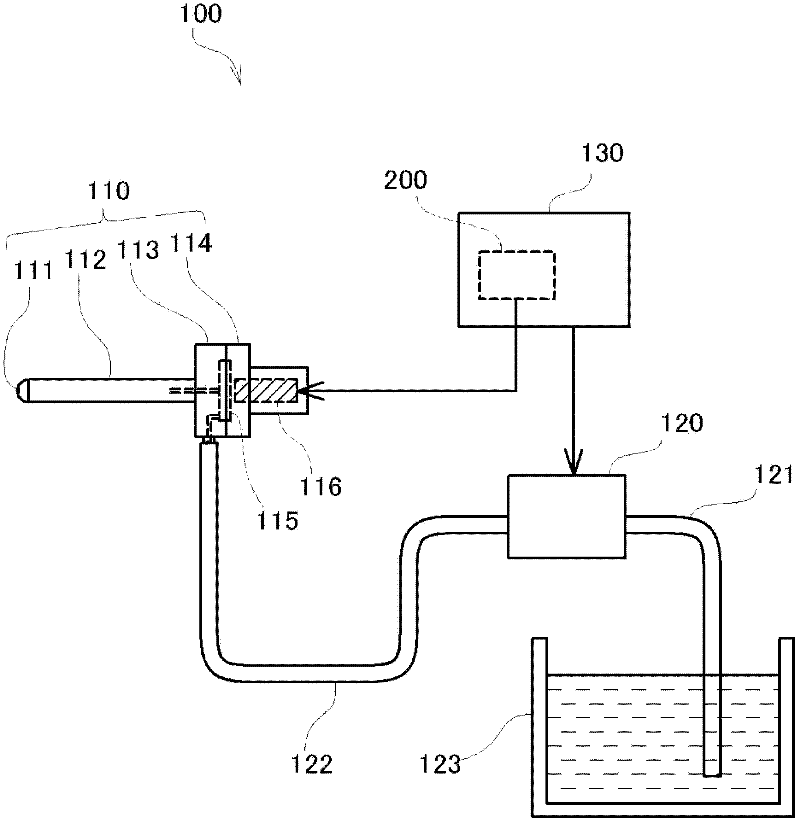

[0045] figure 1 It is an explanatory diagram showing the configuration of the liquid ejection apparatus 100 equipped with the capacitive load drive circuit 200 of the present embodiment. As shown in the figure, the liquid ejection device 100 is roughly composed of an ejection unit 110 that ejects liquid, a supply pump 120 that supplies the liquid ejected from the ejection unit 110 to the ejection unit 110, and a control unit 130 that controls the operations of the ejection unit 110 and the supply pump 120. and so on. For example, the spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com