Semi-solidified sheet cutting method

A prepreg and cutting technology, which is applied in metal processing and other directions, can solve the problem that the circuit board cannot meet the requirements of improving impedance signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

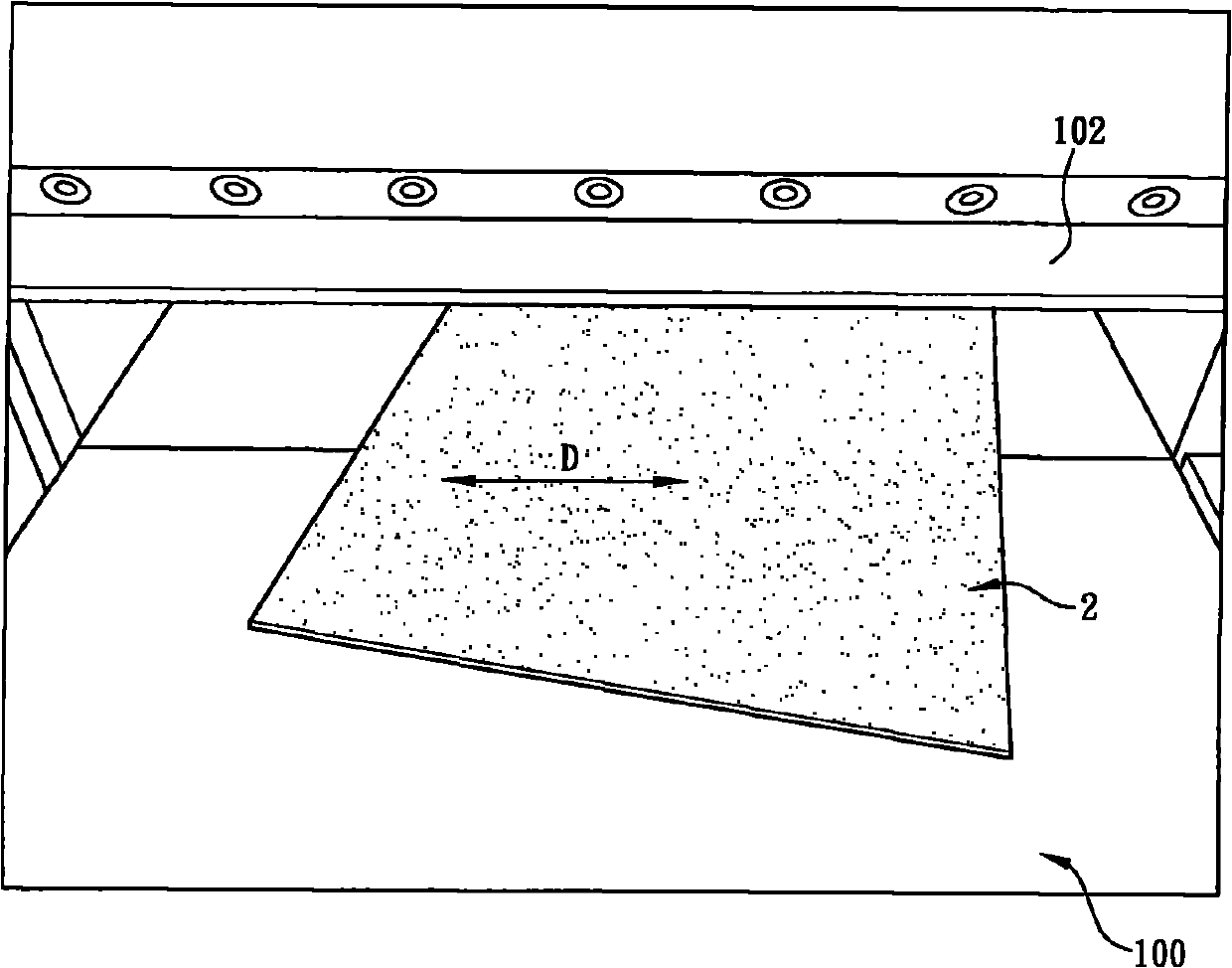

[0018] figure 1 It is a flowchart of a method for cutting a prepreg in a preferred embodiment of the present invention. Figure 2A versus Figure 2B It is a partial schematic diagram of a cutting device and a cutting auxiliary board according to a preferred embodiment of the present invention. image 3 It is a schematic diagram of a rectangular prepreg before and after cutting in a preferred embodiment of the present invention. Please refer to figure 1 , Figure 2A , Figure 2B and image 3 .

[0019] Such as image 3 As shown, the prepreg cutting method provided in this embodiment is used to cut a rectangular prepreg 2 to obtain another rectangular prepreg 3. Wherein, the lengths of the two adjacent sides of the rectangular prepreg 2 can be equal or unequal, as long as the angle between the adjacent sides is 90 degrees. In addition, the size of another rectangular prepreg 3 obtained by cutting can be appropriately adjusted as required.

[0020] In this embodiment, the rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com