Dynamic/static pressure electrical main shaft with automatically-rotating grinding wheel cover

A dynamic and static piezoelectric and grinding wheel technology, which is applied in the field of machine tools, can solve the problems of inconvenient operation of the grinding wheel cover and the inability to truly achieve numerical control, so as to achieve the effect of realizing numerical control automation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

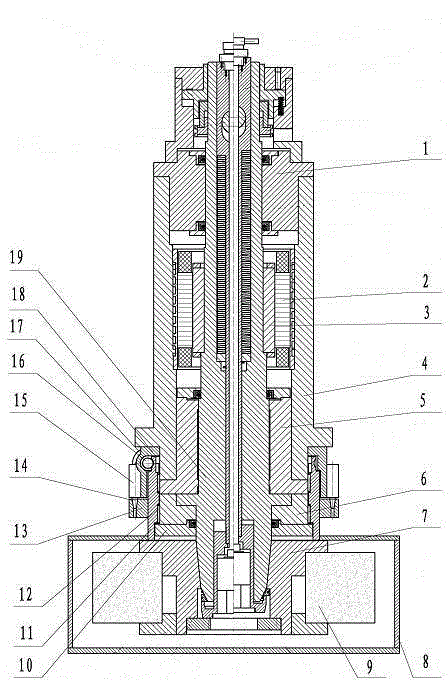

[0009] figure 1 As shown, the main shaft 19 of the present invention is installed in the sleeve 4 through the rear bearing 1 and the front bearing 5, the rotor 3 and the stator 2 are also installed between the main shaft 19 and the sleeve 4, and the grinding wheel chuck 7 is fixed on one end of the main shaft 19, and the grinding wheel A grinding wheel 9 is fixed on the chuck 7, a grinding wheel cover 8 is installed outside the grinding wheel 9, a fixed sleeve 18 and a rotating sleeve 11 are installed on the sleeve 4, a locking disc 13 is installed in the middle of the rotating sleeve 11, and a worm wheel is fixed on the upper part of the rotating sleeve 11 Mechanism, the lower part of the rotating sleeve 11 is fixed with the grinding wheel cover 8, the worm 16 and two locking cylinders 15 are installed on the fixed sleeve 18, the end of the worm 16 is driven by a servo motor 17, and the worm 16 meshes with the worm gear mechanism to lock The end face of the disc 13 is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com