Chinese chestnut stir-frying machine

A technology of chestnut machine and main machine, applied in application, food processing, food science, etc., can solve the problems of difficult operation, waste of manpower and material resources, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

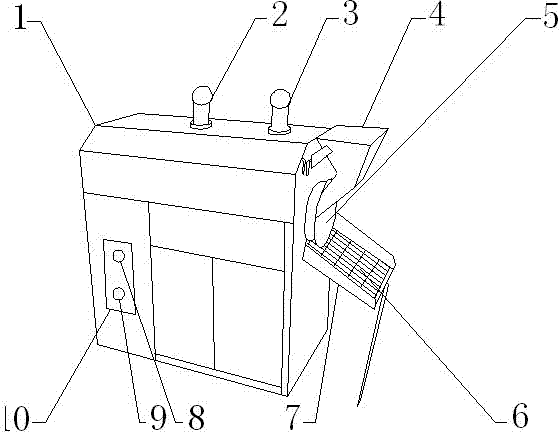

[0010] see figure 1 , stir-fried chestnut machine, including a main machine 1, a numerical control area 10 is arranged on the main machine 1, a drum 5 is arranged inside the main machine 1, a feeder 4 is connected to the upper part of the drum 5, and a receiving material is connected to the lower part of the drum 5. 7, the material catcher 7 is set on the side of the main machine 1, a fault light 2 and a reminder light 3 are arranged above the main machine 1, a steel wire mesh 6 is provided on the material catcher 7, and the size of the steel mesh hole is 0.5*1cm, the numerical control area 10 is provided with a forward rotation switch 8 and a reverse rotation switch 9 .

[0011] This series of machines adopts four-sided light-transmitting design, stainless steel basin-type rotary stirring, far-infrared tube heating, low power consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com