Pneumatic type pipe bender for small pipe fittings

A pneumatic, pipe bending machine technology, applied in the field of pipe bending machines, can solve the problems of large energy consumption, inconvenient operation and complex structure of the workpiece, and achieve the effects of small footprint, reduced energy consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

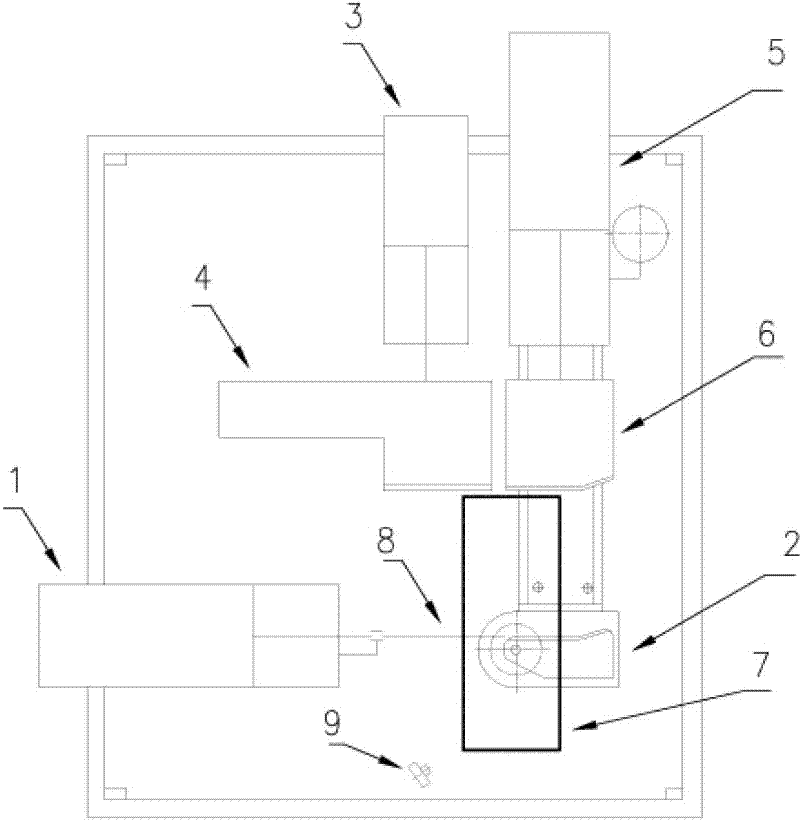

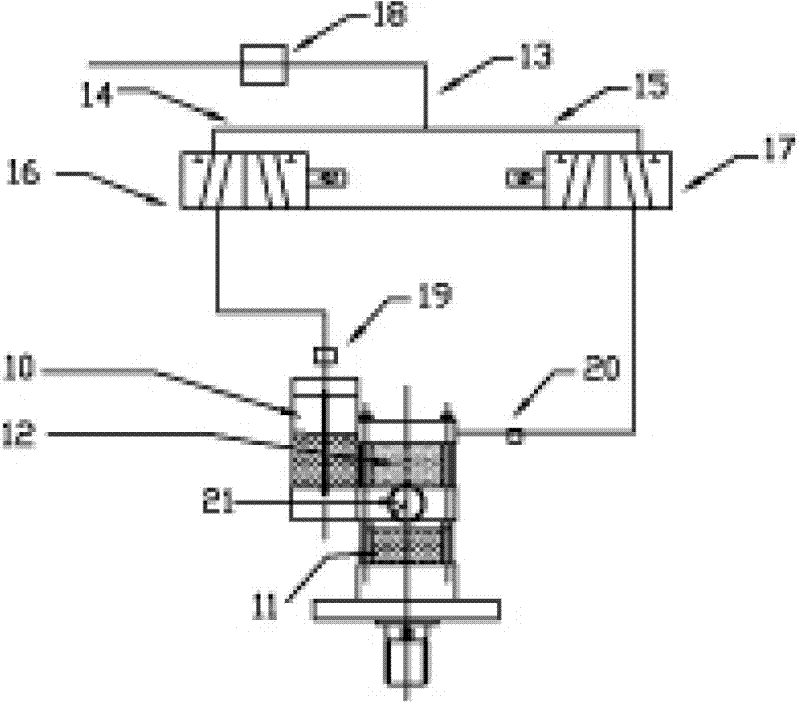

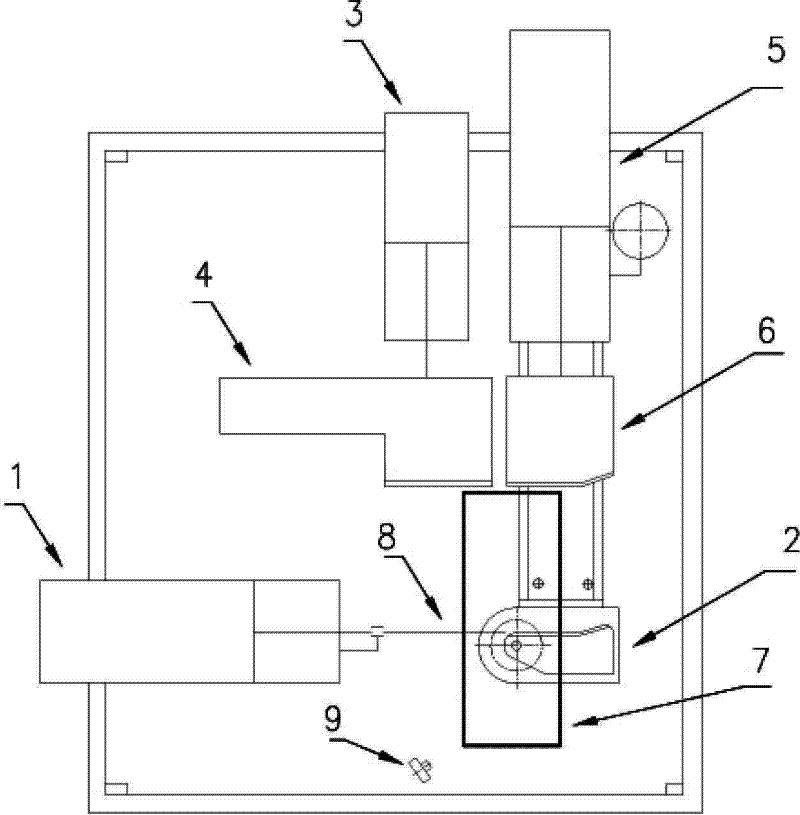

[0015] refer to figure 1 , On the working platform, a small pneumatic pipe bending machine of the present invention includes a pipe bending die 2 and a core-pulling cylinder 1 arranged oppositely. During work, small-sized pipe fitting is enclosed within on the core-pulling rod 8, puts in the pipe groove of bending pipe mold 2 then. On the opposite side of the bending action of the pipe bending die 2, a clamping pipe bending die 6 is vertically opposite to it. Driven by the clamping cylinder 5, the clamping pipe bending die 6 moves forward to cooperate with clamping pipe fittings. A guide clamping die 4 is arranged on the same side as the clamping elbow die 6 . After the action of the clamping elbow mold 6 and the clamping cylinder 5 is delayed for a period of time, the guide clamping mold 4 is driven by the guide cylinder 3 to press the pipe fitting forward to guide the bending and stretching of the pipe fitting. After the guide cylinder 3 is in place, after a delay, the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com