Cleaning method using uniformly and stably jet cleaning agent formed by separately using liquid carbon dioxide or mixing liquid carbon dioxide and compressed gas

A technology of liquid carbon dioxide and compressed gas, applied in the cleaning method using liquid, the cleaning method using gas flow, chemical instruments and methods, etc., can solve the problems of high price of dry ice granulator, unbearable equipment investment and high cost , to achieve the effect of uniform and stable injection, low cost, and elimination of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

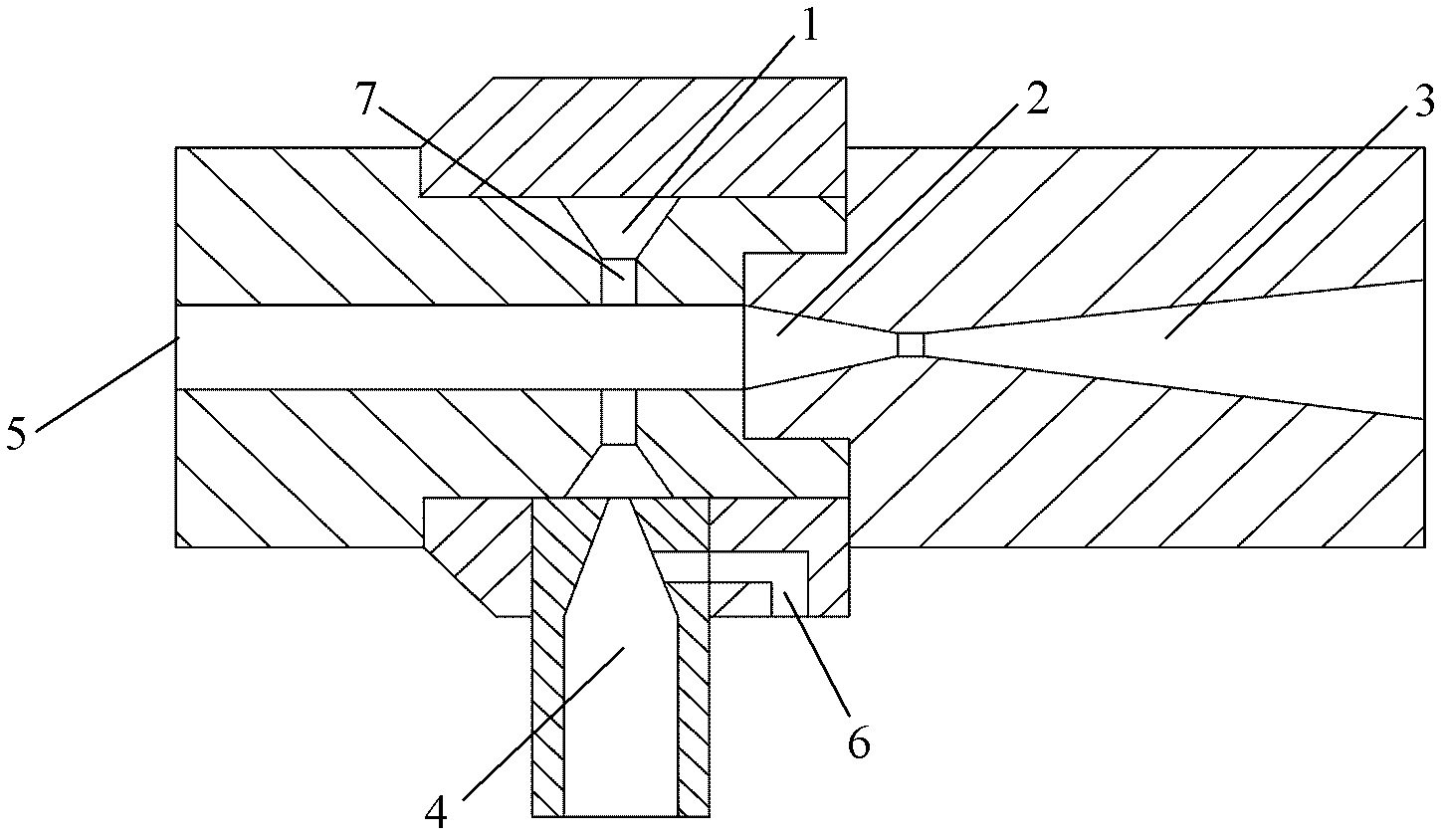

Method used

Image

Examples

Embodiment 1

[0071] Unit: Yuanqing Aluminum (China) Co., Ltd. (Japanese-funded enterprise)

[0072] Location: Die-casting workshop of Yuanjing Aluminum Co., Ltd., Kunshan City, Jiangsu Province

[0073] Cleaning object: on-line cleaning of release agent for die-casting molds with upper and lower molds.

[0074] Cleaning conditions: Under ambient conditions (0°C, atmospheric pressure), liquid carbon dioxide is transported at a temperature of 0°C and a pressure of 60 Bar; the flow rate of the liquid carbon dioxide is 0.2kg / min; the flow rate of compressed air is 3-5M 3 / min, the pressure is 0.5~0.7mpa; the liquid carbon dioxide is depressurized to 5Bar through the liquid decompression area of the spray gun, and then mixed with compressed air evenly and stably, and then sprayed on the cleaning object. The spray speed is 320 m / s, and the spray flow rate is 0.2 liters of liquid carbon dioxide and 4 cubic meters of compressed air per minute.

[0075] Comparative effect: Compared with sandbla...

Embodiment 2

[0081]Unit: Sachs Auto Parts Systems (Shanghai) Co., Ltd.

[0082] Location: Shanghai Minghua Chemical Technology Co., Ltd. (warehouse)

[0083] Cleaning object: dirt cleaning on the surface of shock absorbers of high-speed trains.

[0084] Cleaning conditions: Under room temperature (15°C, atmospheric pressure), liquid carbon dioxide is transported at a temperature of -20°C and a pressure of 40 Bar; the flow rate of the liquid carbon dioxide is 0.5kg / min; the flow rate of compressed air is 3-5M 3 / min, the pressure is 0.5~0.7mpa; the liquid carbon dioxide is depressurized to 5Bar through the liquid depressurization area of the spray gun, and then mixed with compressed air evenly and stably, and then sprayed on the cleaning object. The spray speed is 450 m / s, and the spray flow rate is 0.5 liters of liquid carbon dioxide and 4 cubic meters of compressed air per minute.

[0085] Contrast effect: High-pressure water gun was used ineffective; dry ice cleaning was too costly t...

Embodiment 3

[0090] Unit: Shanghai Kainajie Chemical Research Institute

[0091] Cleaning object: Dirt on car paint surface / engine compartment

[0092] Cleaning conditions: Under room temperature conditions (30°C, atmospheric pressure), liquid carbon dioxide is transported at a temperature of -10°C and a pressure of 20Bar; the flow rate of the liquid carbon dioxide is 1kg / min; the flow rate of compressed air is 3-5M 3 / min, the pressure is 0.5~0.7mpa; the liquid carbon dioxide is depressurized to 5Bar through the liquid decompression area of the spray gun, and then mixed with compressed air evenly and stably, and then sprayed on the cleaning object. The spray speed is 400 m / s, and the spray flow rate is 1.0 liters of liquid carbon dioxide and 4 cubic meters of compressed air per minute.

[0093] Cleaning results: It can quickly remove the paint surface of the car body, the dirt and insect corpses on the surface of the wheel hub, especially for plastic parts.

[0094] The dirt on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com