Beneficiation method for separating zinc sulfide ores from sulphur in wet-method zinc smelting slag

A technology of zinc hydrometallurgy and ore dressing method, applied in wet separation, chemical instruments and methods, solid separation, etc., can solve the problems of zinc resource loss, unfavorable sulfur processing and utilization, and reduce the quality of sulfur products, so as to improve the utilization rate , good sorting effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

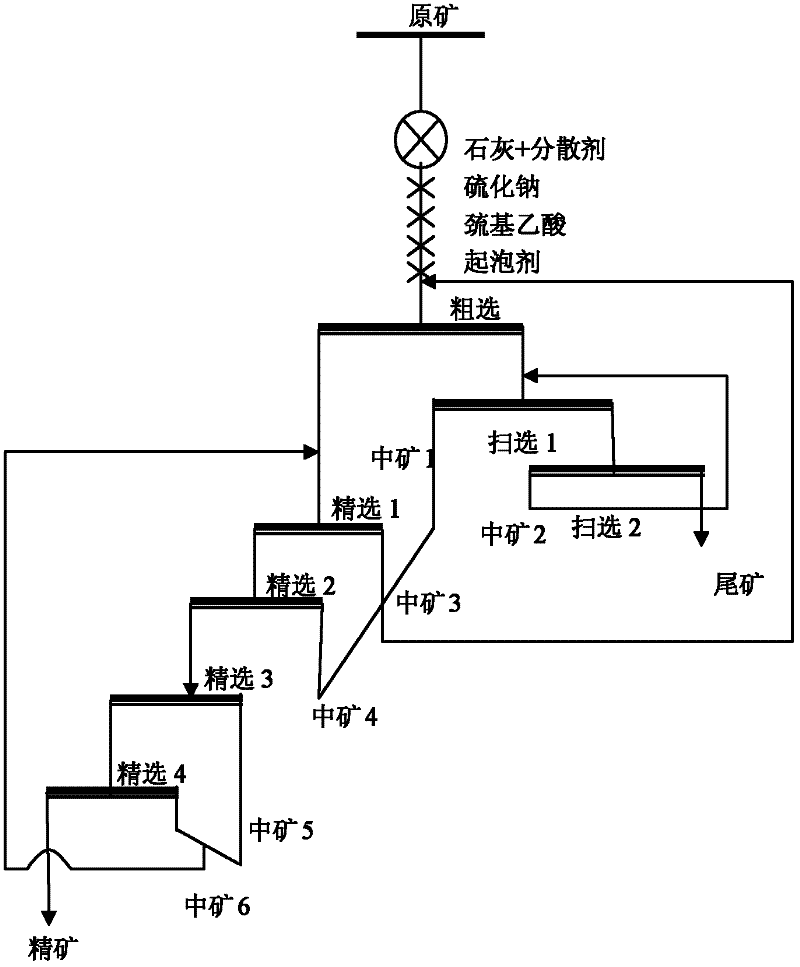

[0044]The raw ore sample is a zinc pressurized acid leaching slag sample from a wet zinc smelting plant. The dispersant sodium hexametaphosphate was added to the mill at a dosage of 200 g / ton, and quicklime was added to adjust the pH value to 6.5, and then the ore was ground to -0.074. The mm particle size accounts for 90%. It is a closed-circuit flotation process after one roughing, two sweepings and four selected selections. See the process flow figure 1 , add sodium sulfide and thioglycolic acid two kinds of depressants simultaneously during roughing, and wherein sodium sulfide consumption is 2000 grams / ton, and thioglycolic acid consumption is 300 grams / ton, foaming agent 40 grams / ton, flotation product is filtered, Drying, the test results are as follows:

[0045]

[0046] The result of the closed-circuit test shows that the present invention can be well applied to the flotation separation of zinc and sulfur in the ore sample, and better product indexes can be obtained...

Embodiment 2

[0048] The raw ore sample is a zinc pressurized acid leaching slag sample from a wet zinc smelting plant. The dispersant sodium hexametaphosphate was added to the mill at a dosage of 300 g / t, and quicklime was added to adjust the pH value to 6.5, and then the ore was ground to -0.074. The mm particle size accounts for 90%. It is a closed-circuit flotation process after one roughing, two sweepings and four selected selections. See the process flow figure 1 , add sodium sulfide and thioglycolic acid two kinds of inhibitors simultaneously when roughing, and wherein sodium sulfide consumption is 3000 grams / ton, thioglycolic acid consumption is 250 grams / ton, foaming agent 40 grams / ton, flotation product is filtered, Drying, the test results are as follows:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com