Sheets capable of reducing tar content of cigarettes and manufacture method thereof

A technology of thin slices and content, applied in tobacco, tobacco processing, application, etc., can solve the problems of high tar content and unsatisfactory sensory quality of cigarette products, so as to reduce the tar content of cigarettes, improve the high tar content of cigarettes, and sensory evaluation. Good quality suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further illustrate the present invention below in conjunction with specific embodiment:

[0015] Dry and crush conventional flake raw materials and Chinese herbal medicine powder, then mix them, add flake glue and flavoring sugar, stir and mix evenly to make a wet powder, and then pass the wet powder through a three-press system to be pressed into a thickness of about 0.11-0.13 mm, wet flakes with a moisture content of about 32.0-35.0%, and then pass the wet flakes through a dryer to become tobacco flakes with a moisture content of 16-18%.

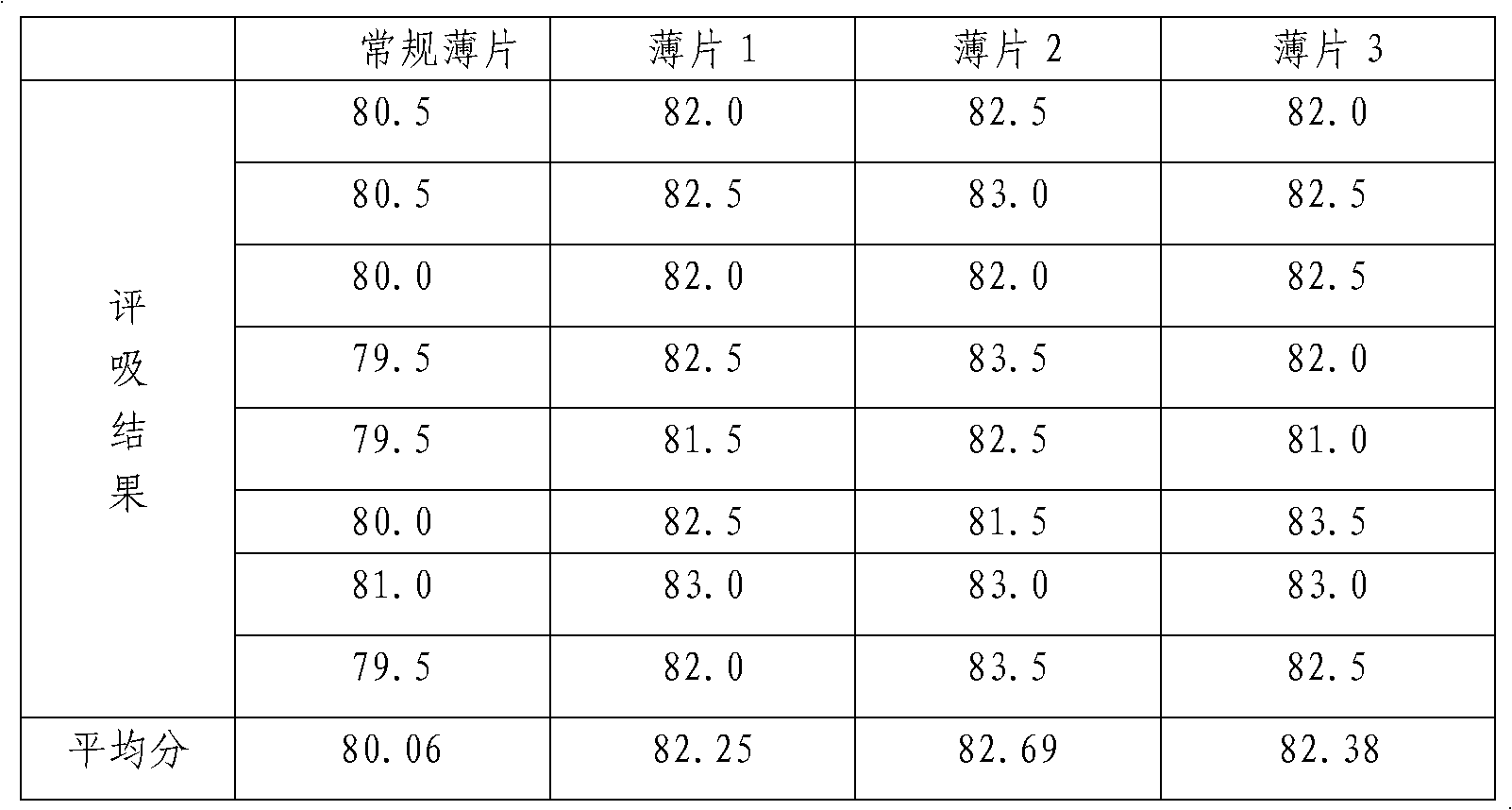

[0016] The formula of described Chinese herbal medicine powder is as shown in table 1:

[0017]

Mint%

Osmanthus fragrans%

Chenpi%

Licorice%

lotus leaf%

chrysanthemum%

Flake 1

20

10

20

25

20

5

Flake 2

18

9

17

28

21

7

flakes 3

15

5

15

30

25

10

[0018] Formulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com