Edible food fresh-keeping coating and preparation method thereof

A technology of food preservation and film coating, which is applied in food preservation, food science, and preservation of meat/fish with a coating protective layer, etc. It can solve the problems of water preservation and freshness preservation and anti-corrosion effects need to be improved, so as to improve the immunity of the body and the preparation process Simple, good water retention and freshness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The food fresh-keeping coating film comprises 5.0% of inulin, 2.0% of glacial acetic acid solution, 0.5% of chitosan, and the rest is water.

[0017] Preparation: by weight percentage, weigh 5.0% inulin and 0.5% chitosan and dissolve in water, stir until completely dissolved, then add 2.0% glacial acetic acid, stir and dissolve to obtain a fresh-keeping coating solution. Soak the sharp peppers that need to be kept fresh in the prepared fresh-keeping coating solution for 10 seconds to ensure uniform coating. After coating, place them on a porcelain plate in the natural environment to measure the water loss rate of the sharp peppers and observe their freshness Effect, wherein the evaluation of the preservation effect is based on the full score of 10 for freshness. The results of water loss rate and fresh-keeping effect are as follows:

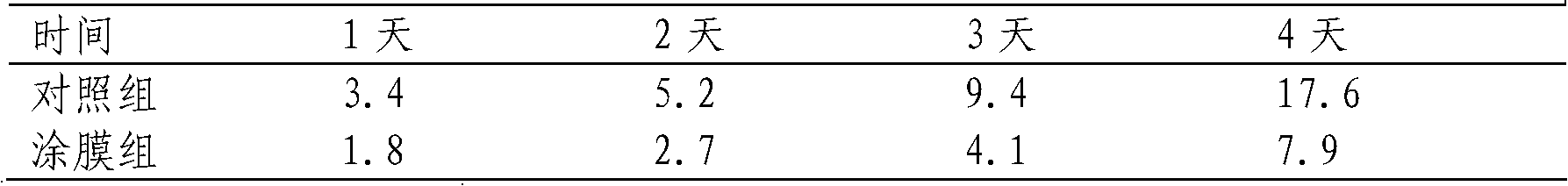

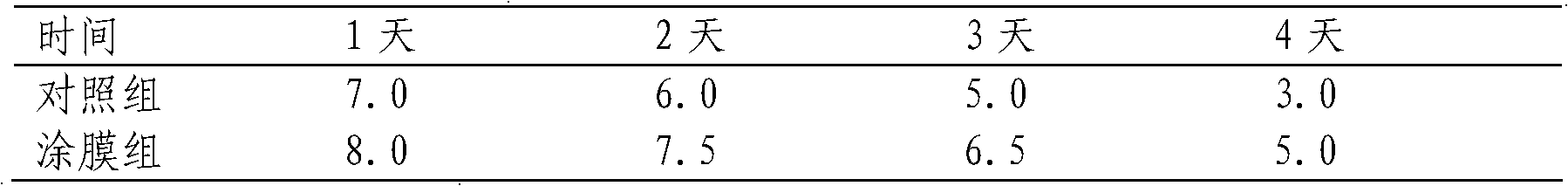

[0018] The water loss rate (%) of sharp pepper after table 1 coating

[0019]

[0020] Note: water loss rate (%)=(initial weight of ...

Embodiment 2

[0025] The food fresh-keeping coating film contains 8.0% of inulin, 3% of glacial acetic acid solution, 0.8% of chitosan, and the rest is water.

[0026] Preparation: by weight percentage, weigh 8.0% inulin and 0.8% chitosan and dissolve in water, stir until completely dissolved, then add 3.0% glacial acetic acid, stir and dissolve to obtain a fresh-keeping coating solution. Soak the tangerines that need to be kept fresh in the prepared fresh-keeping coating solution for 30 seconds to ensure uniform coating. After coating, place them on a porcelain plate in the natural environment to measure the water loss rate of tangerines and observe their freshness. Effect, wherein the evaluation of the preservation effect is based on the full score of 10 for freshness. The results of water loss rate and fresh-keeping effect are as follows:

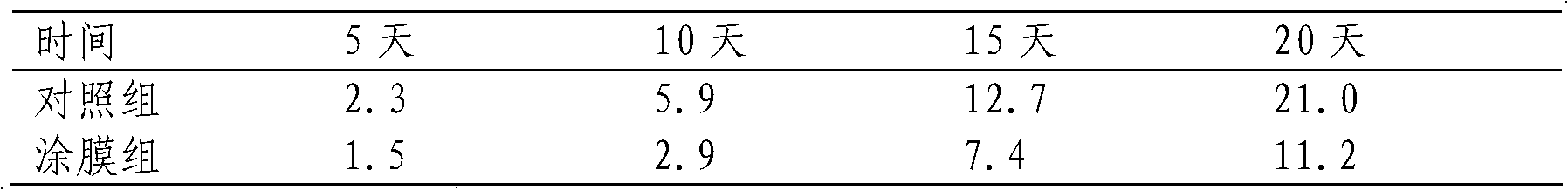

[0027] Water loss rate (%) of tangerine after table 3 film coating

[0028]

[0029] Note: water loss rate (%)=(initial weight of tangerine-weig...

Embodiment 3

[0034] The food fresh-keeping coating film comprises 10.0% of inulin, 2.0% of glacial acetic acid solution, 1.0% of chitosan, and the rest is water.

[0035] Preparation: by weight percentage, weigh 10.0% inulin and 1.0% chitosan and dissolve in water, stir until completely dissolved, then add 2.0% glacial acetic acid, stir and dissolve to obtain a fresh-keeping coating solution. Soak the chilled meat that needs to be kept fresh in the prepared fresh-keeping coating solution for 60 seconds and then take it out. The shelf life of the coated chilled meat at 0-4°C can be extended by 15-20 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com