Kefir fermented dairy product and preparation process thereof

A technology for fermented dairy products and preparation process, which is applied in the field of fermented kefir dairy products and their preparation, which can solve problems such as complicated process, irritating taste and uncontrollable taste of fermented kefir dairy products, and achieve simple and improved production process. Product taste, easy to add effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

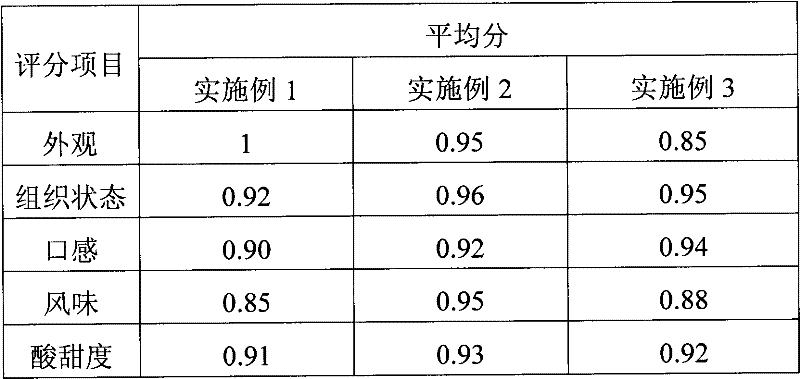

Embodiment 1

[0051] Raw material formula: Anti-resistant milk 93%, white granulated sugar 6.148%, starch 0.1%, agar 0.2%, pectin 0.5%, kefir essence 0.05%, kefir basic starter KM-010.002% (0.02g / kg raw material ).

[0052] Raw material standard:

[0053] The protein content of antibiotic-free milk is 2.5%. Antibiotic-free milk is the antibiotic-free raw milk that has passed the fermentation experiment. According to the protein content in the raw milk, the protein content is standardized to 2.5% by adding water for dilution;

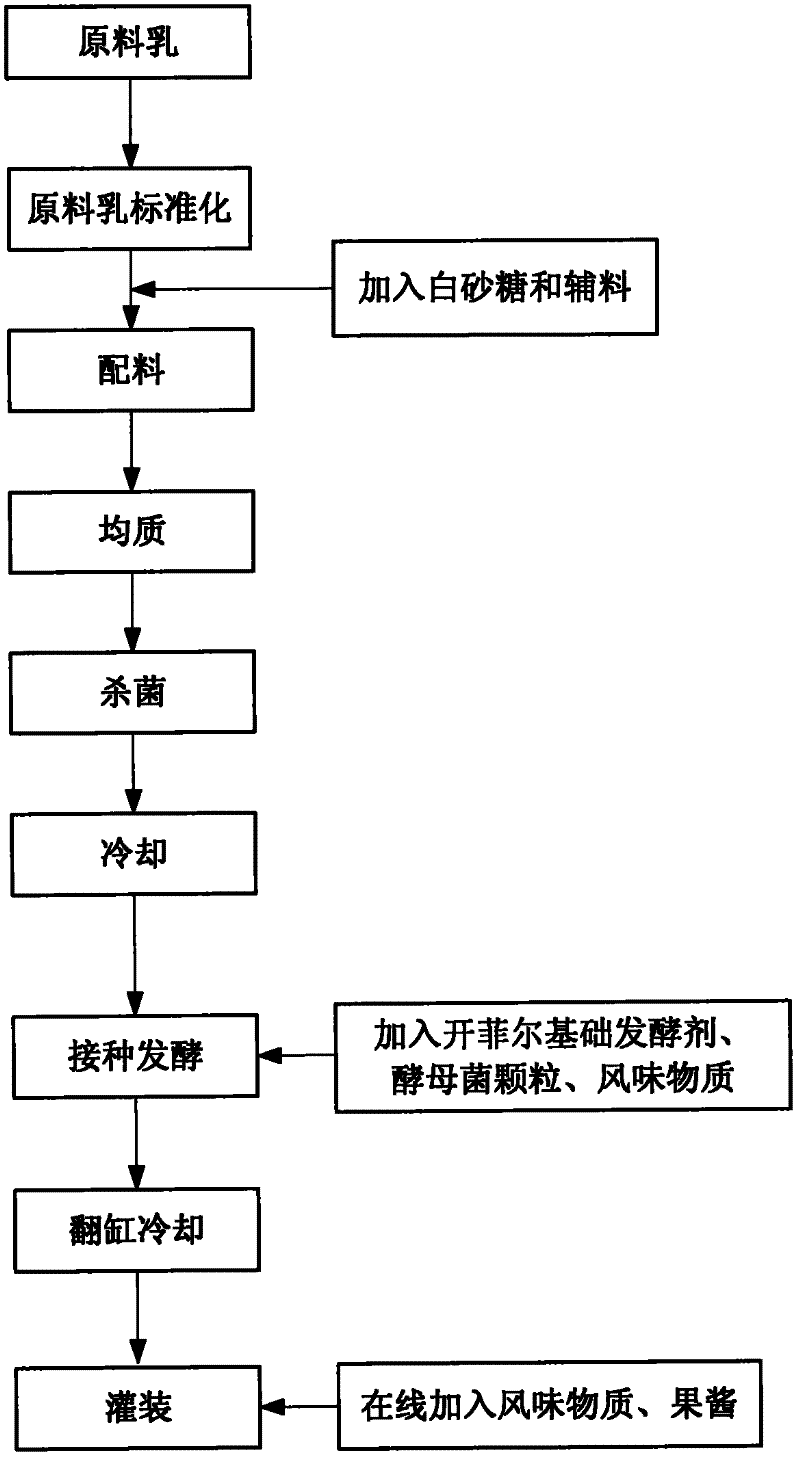

[0054] preparation process (such as figure 1 shown):

[0055] 1. Ingredients: Mix starch, pectin, agar, and white sugar evenly, dissolve in antibiotic-free milk at 40°C, and stir to dissolve for 15 minutes.

[0056] 2. Homogeneous: the total pressure is 19MPa, the primary pressure is 16MPa, the secondary pressure is 3MPa; the temperature is 60°C.

[0057] 3. Sterilization: 90°C, 15 minutes.

[0058] 4. Cooling: Cool the feed liquid to 25°C after sterilization.

...

Embodiment 2

[0065] Raw material formula: 90.37% anti-antibiotic milk, 6% white sugar, 1.0% starch, 0.05% pectin, 0.03% agar, 1.85% concentrated apple juice, 0.65% chicory fiber (dietary fiber), 0.04% yogurt essence, kefir Basic starter KM-010.008% (0.08g / kg raw material), yeast granules 0.002% (0.02g / kg raw material).

[0066] Raw material standard:

[0067] The protein content of antibiotic-free milk is 3.1%. Antibiotic-free milk is the antibiotic-free raw milk that has passed the fermentation experiment. According to the protein content in the raw milk, the protein content is standardized to 3.1% by adding whey protein powder;

[0068] Concentrated apple juice: decolorized and deacidified, sugar content 70%±1%, color value ≥95, total acid ≤0.1%.

[0069] Chicory fiber: Chicory fiber content > 90%, pH: 5.0-7.0.

[0070] preparation process (such as figure 1 shown):

[0071] 1. Ingredients: Mix starch, pectin, agar, white sugar, and concentrated apple juice evenly, dissolve in antibio...

Embodiment 3

[0081] Raw material formula: Anti-resistant milk 85%, white sugar 8.0%, starch 1.0%, pectin 0.2%, vitamins (vitamin A, vitamin D) 0.0009125%, strawberry jam 5.7190875%, sucralose 0.01%, strawberry essence 0.03%, Kefir essence 0.02%, kefir basic starter KM-010.01% (0.1g / kg raw material), yeast granules 0.01% (0.1g / kg raw material).

[0082] Raw material standard:

[0083] The protein content of antibiotic-free milk is 3.5%. Antibiotic-free milk is the antibiotic-free raw milk that has passed the fermentation experiment. According to the protein content in the raw milk, the protein content is adjusted to 3.5% by adding whey protein powder;

[0084] Strawberry jam: fruit grain content ≥ 50%, sugar content 40% ± 5%.

[0085] preparation process (such as figure 1 shown):

[0086] 1. Ingredients: Mix starch, pectin, white sugar, sucralose and vitamins evenly, dissolve in antibiotic-free milk at 42°C, and dissolve for 20 minutes.

[0087] 2. Homogeneous: the total pressure is 21M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com