Flex-rigid combined board and manufacturing method of flex-rigid combined board

A technology of rigid-flex board and manufacturing method, which is applied in the structural connection of printed circuits, printed circuit parts, printed circuit assembly of electrical components, etc., and can solve the problem of uneven board surface and poor bonding effect of soft board cover film and prepreg Good, soft board is easy to break and other problems, to achieve the effect of uniform glue flow, avoid soft board breakage, and increase support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

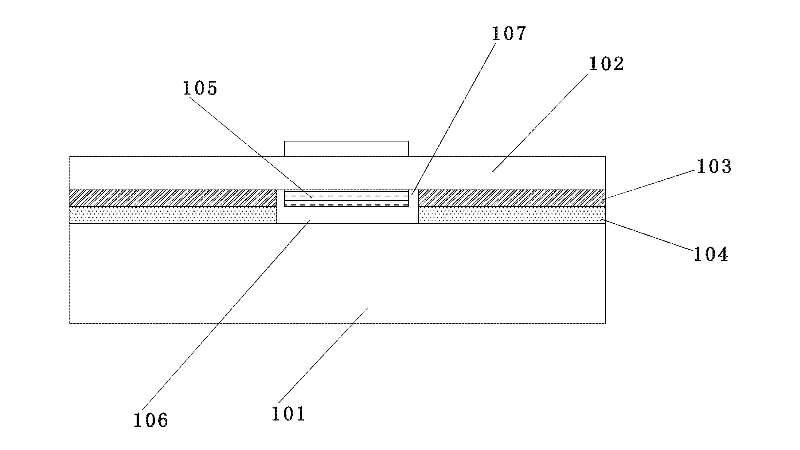

[0027] The present invention provides a rigid-flex board and its manufacturing method. It mainly opens windows of different sizes on the two layers of prepreg between the soft and hard boards, and the soft board covering film is located in the above-mentioned windows, and Overlap and press one of them to achieve the purpose of increasing the support strength and avoiding the breakage of the soft board, while ensuring the bonding effect of the soft board cover film and the curing sheet; improving the flatness of the rigid-flex joint of the circuit board.

[0028] Such as figure 2 as shown, figure 2 It is a structural schematic diagram of the rigid-flex board of the present invention. A rigid-flex board according to the present invention includes a hard board 201 and a soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com