Stepping motor drive circuit and control method thereof

A technology of stepping motor and driving circuit, applied in the direction of motor generator control, control system, electrical components, etc., can solve the problems of occupying large PCB space, many wiring harnesses at the motor end, out-of-step, over-step and stalled rotor, etc. The effect of occupying less PCB space, increasing the space capacity of the car, and reducing the number of wire harnesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention occupies a small PCB space to achieve the purpose of increasing the space capacity in the car, shares the motor phase lines, controls the operation of the corresponding stepping motor by controlling each power line, and reduces the number of wiring harnesses to simplify external wiring.

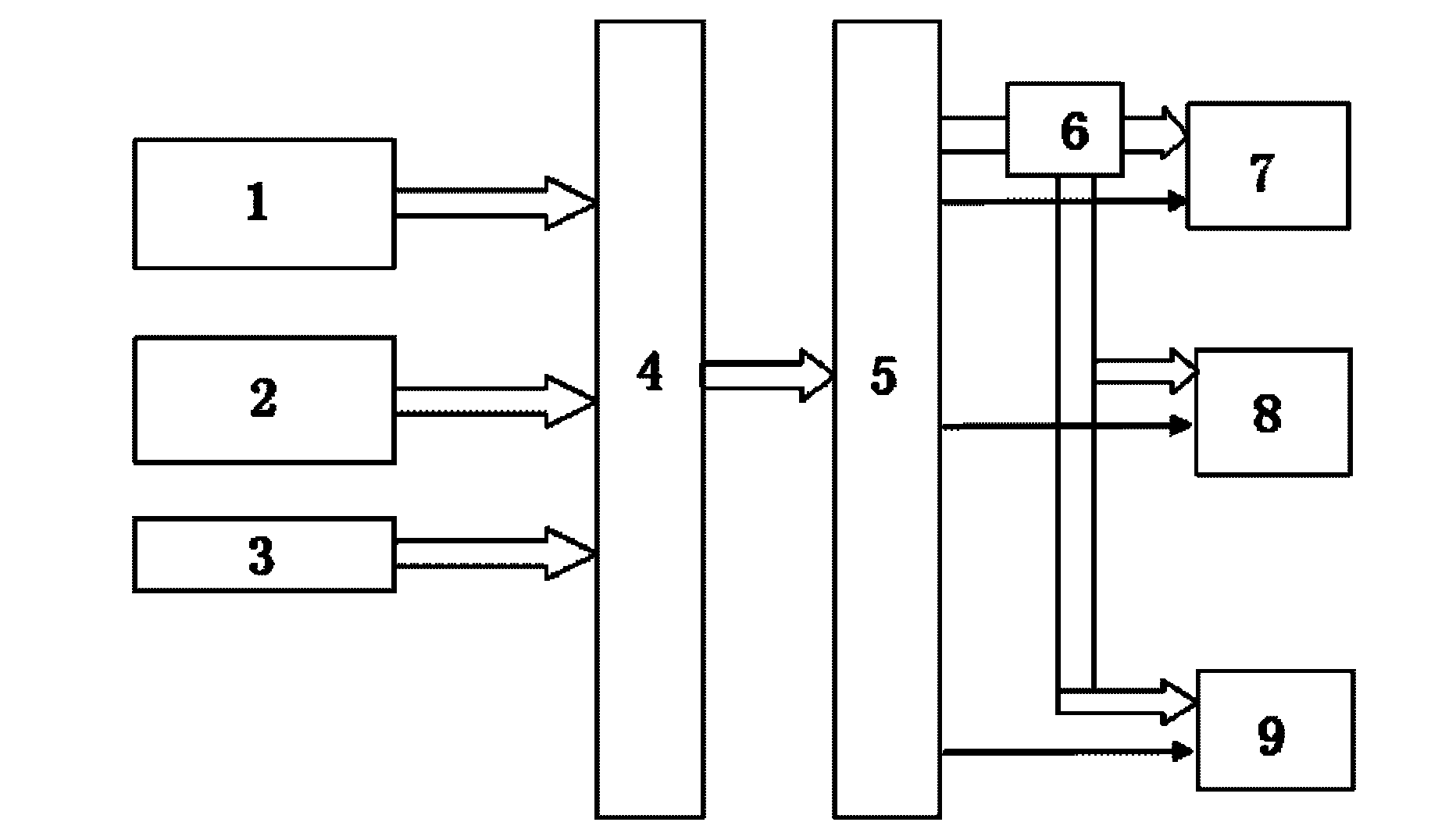

[0024] Such as figure 1 As shown, the present invention is that the power signal input filter protection circuit 1, the motor current detection circuit 2, the key scanning circuit 3 are simultaneously connected to the control chip 4, and the control chip 4 sends a control signal to a motor drive chip 5; inner and outer circulation motor 7, hybrid The damper motor 8 and the mode motor 9 share four phase lines to connect to the motor drive chip 5, and they are connected to the motor drive chip 5 through an independent motor power line, so as to use the internal and external circulation motor 7, the hybrid damper motor 8, and the mode motor 9 The principle that it cannot work at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com