Cell piece possessing back reflection layer and manufacturing method thereof

A technology of back reflective layer and reflective layer, which is applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of three-dimensional back reflective layer with many raw materials, complicated production process, and increased production cost, so as to facilitate thinning and strengthening The effect of simple absorption and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

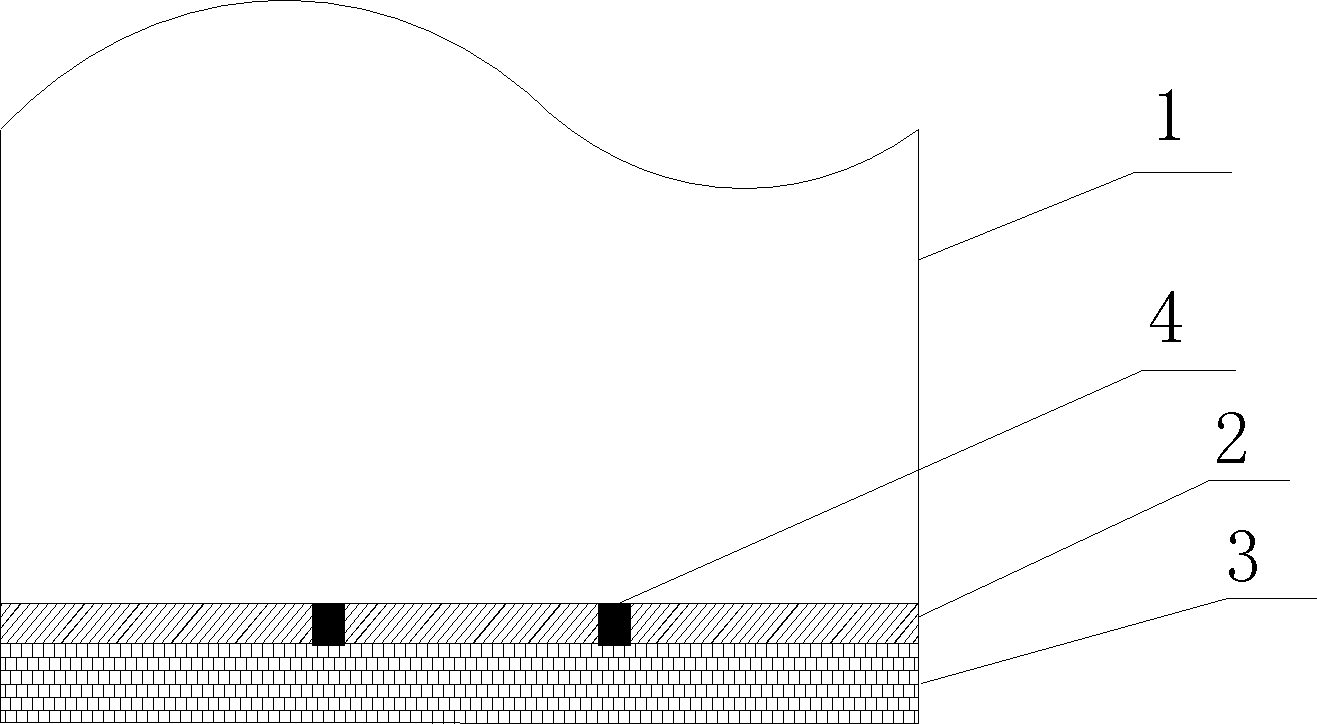

[0021] Embodiment 1 The preparation method of the battery sheet of the present invention

[0022] Take the silicon wafer on which the front anti-reflection film has been prepared, and on the back side, PECVD prepares 90nm thick SiO x Reflective layer; screen-printed aluminum paste, distributed in dots, and the area in contact with the back of the silicon wafer accounts for 10% of the entire back. The front electrode is then printed and sintered to form a localized aluminum back field; then, the surface of the SiOx reflective layer is evaporated. A layer of Al metal layer is plated with a thickness of 1 μm, that is, a battery sheet with a back reflection layer is obtained.

Embodiment 2

[0023] Embodiment 2 The preparation method of the battery sheet of the present invention

[0024] Take the silicon wafer on which the front anti-reflection film has been prepared, and on the back side, PECVD prepares 90nm thick SiO x Reflective layer; screen-printed aluminum paste, distributed in a mesh, and the area in contact with the back of the silicon wafer accounts for 5% of the entire back. Then the front electrode is printed and sintered to form a localized aluminum back field; then, on the SiO x A layer of Al metal layer is vapor-deposited on the surface of the reflective layer, and the thickness is 1 μm, that is, a battery sheet with a back reflective layer is obtained.

Embodiment 3

[0025] Embodiment 3 The preparation method of the battery sheet of the present invention

[0026] Take the silicon wafer on which the front anti-reflection film has been prepared, and on the back side, 85nm thick SiO is prepared by PECVD x Reflective layer; screen-printed aluminum paste, distributed in a mesh shape, the area in contact with the back of the silicon wafer accounts for 6% of the entire back, and then the front electrode is printed and sintered to form a localized aluminum back field; then, on the SiO x A layer of Al metal layer is vapor-deposited on the surface of the reflective layer, and the thickness is 0.7 μm, that is, a battery sheet with a back reflective layer is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com