High-precision phase shift device of lateral shear interferometer

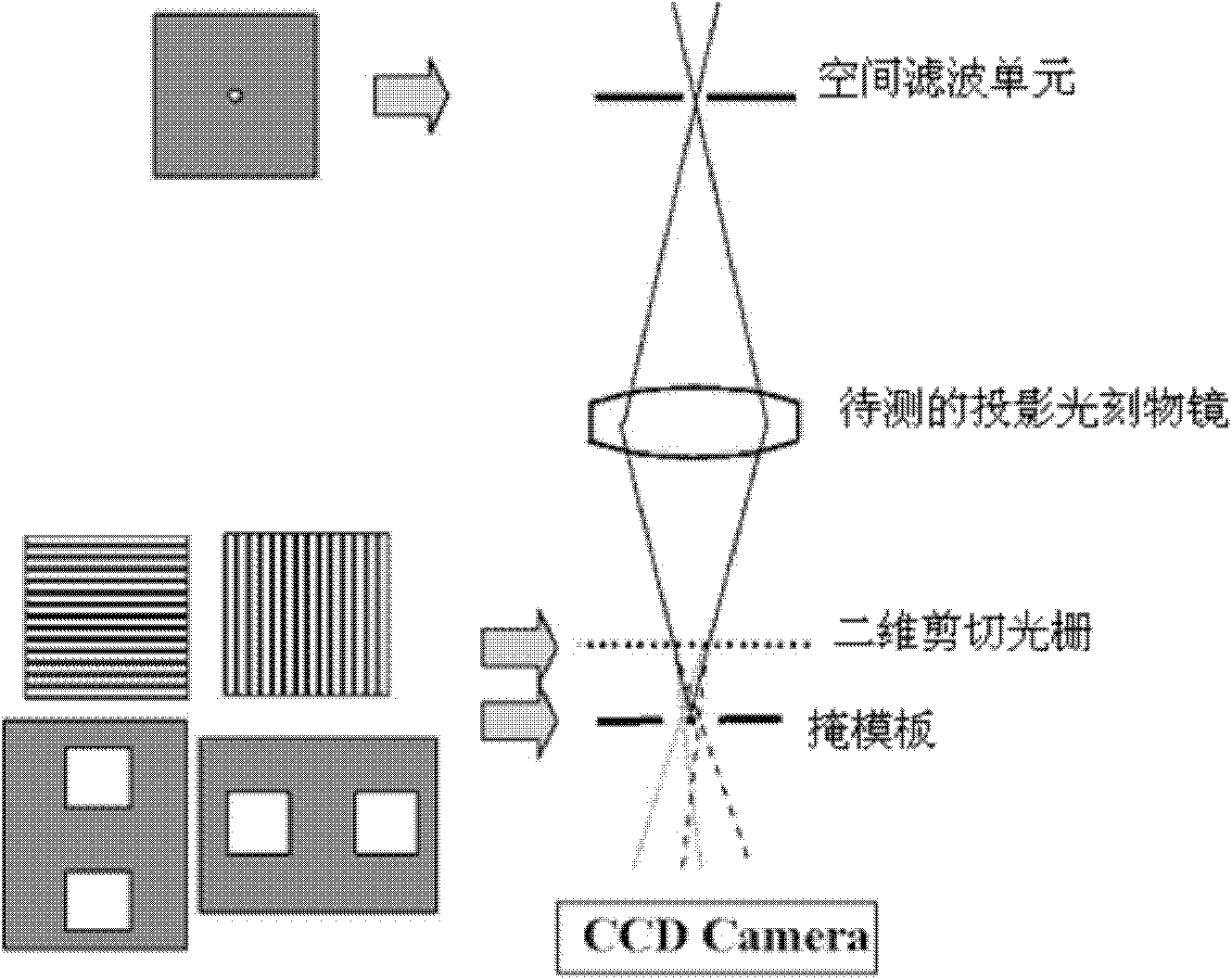

A transverse shearing and interferometer technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of low response frequency, large axial size, large size, etc., and achieve high dynamic response, compact axial size, high The effect of motion resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

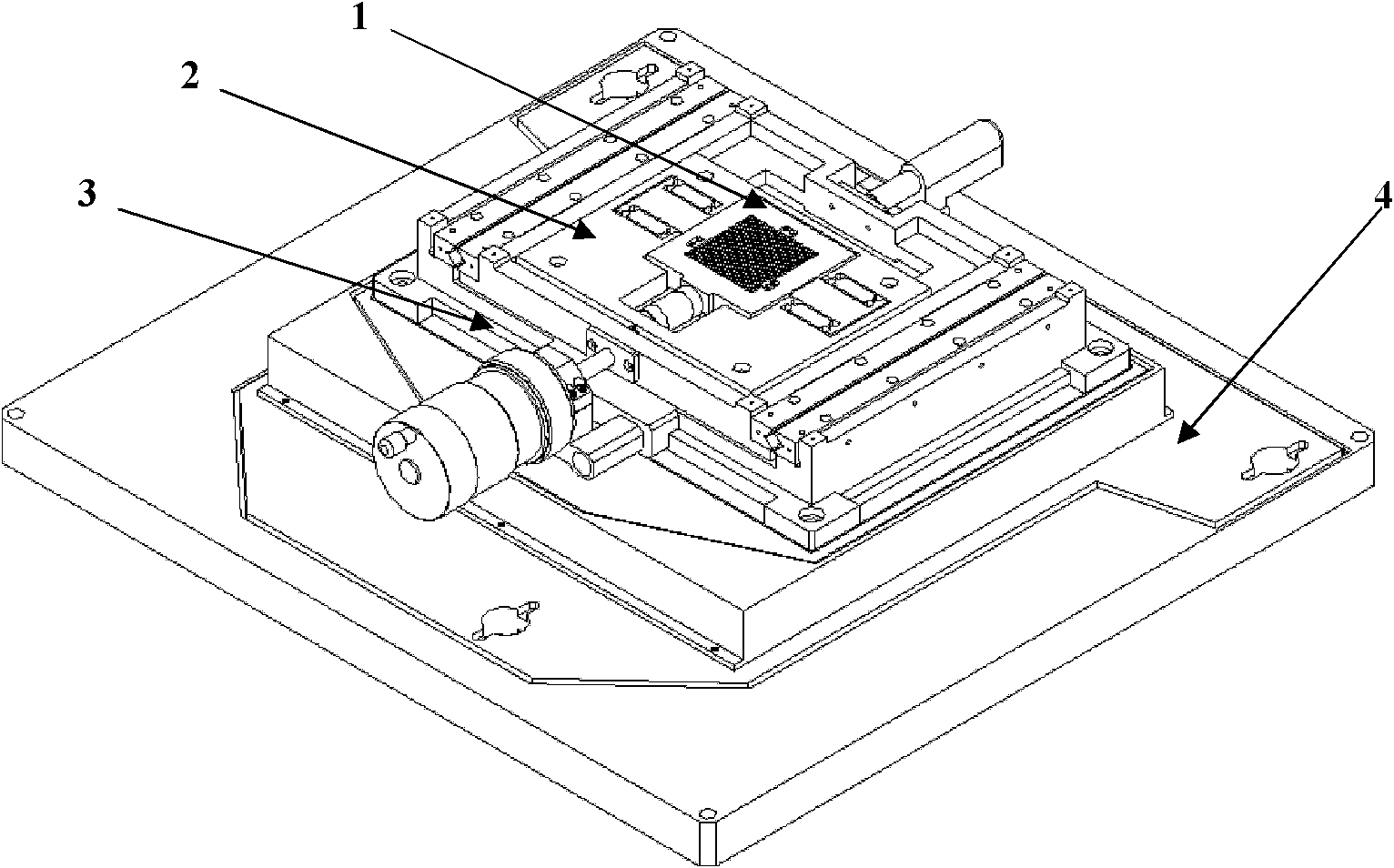

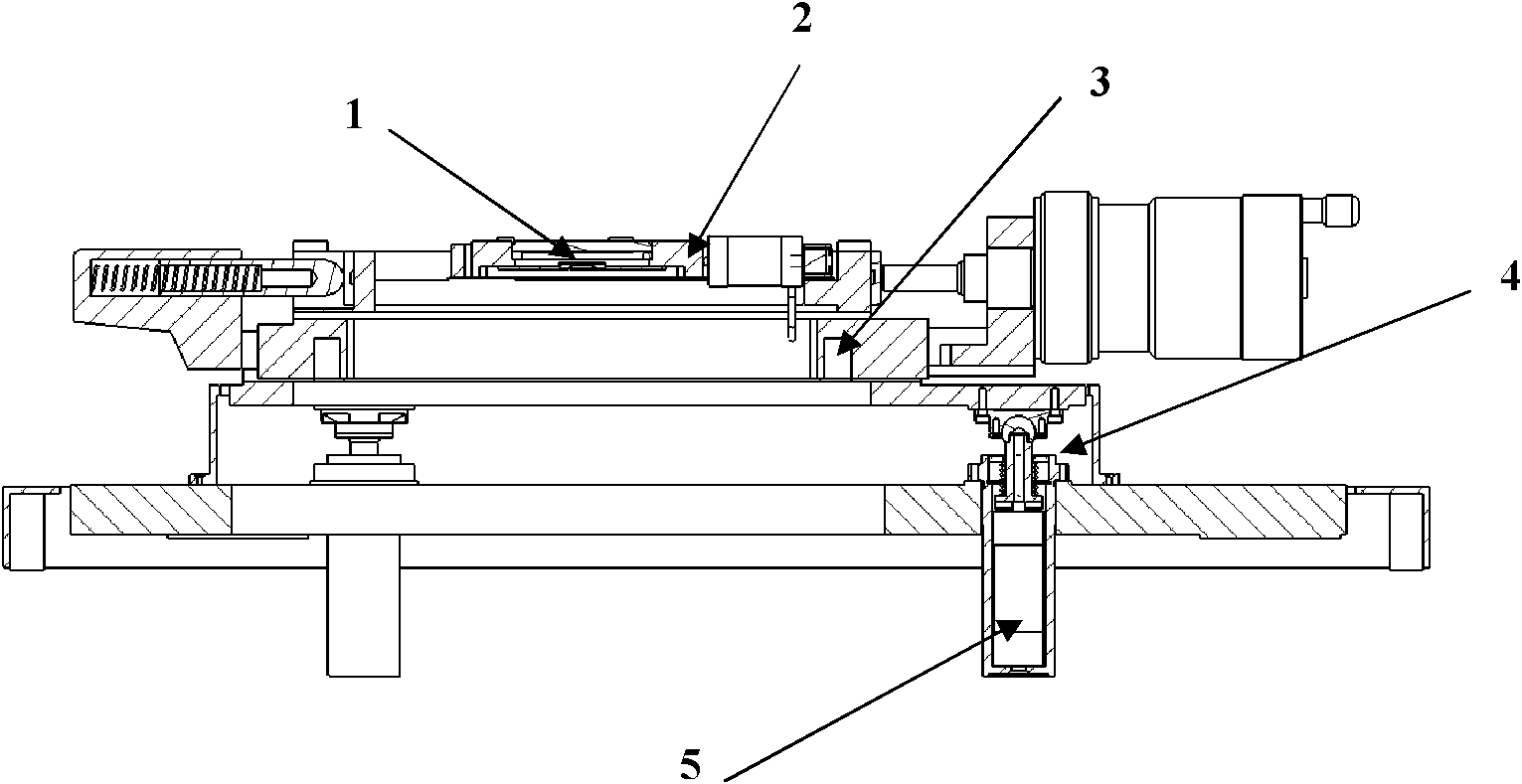

[0018] A high-precision transverse shearing interferometer phase shifting device, a shearing grating 1, a mask plate assembly and a base 4, the device also includes: a one-dimensional small-stroke high-resolution displacement assembly 2, a one-dimensional large-stroke displacement assembly 3 and Phase shifter leveling assembly 5; the shearing grating 1 is located in the one-dimensional small-stroke high-resolution displacement assembly 2 and fixed on the one-dimensional small-stroke high-resolution displacement assembly 2; the mask plate assembly is fixed on the one-dimensional small stroke On the fixed substrate 7 at the bottom of the high-resolution displacement assembly 2, it remains relatively stationary with the one-dimensional small-stroke high-resolution displacement assembly 2, and the one-dimensional small-stroke high-resolution displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com