A large-load, high-precision, cross-scale piezoelectric linear motor based on compliant foot drive

A linear motor, cross-scale technology, applied in piezoelectric/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of short life, low resolution, and low bearing capacity of linear motors and other problems, to achieve the effect of large load capacity, high motion resolution and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

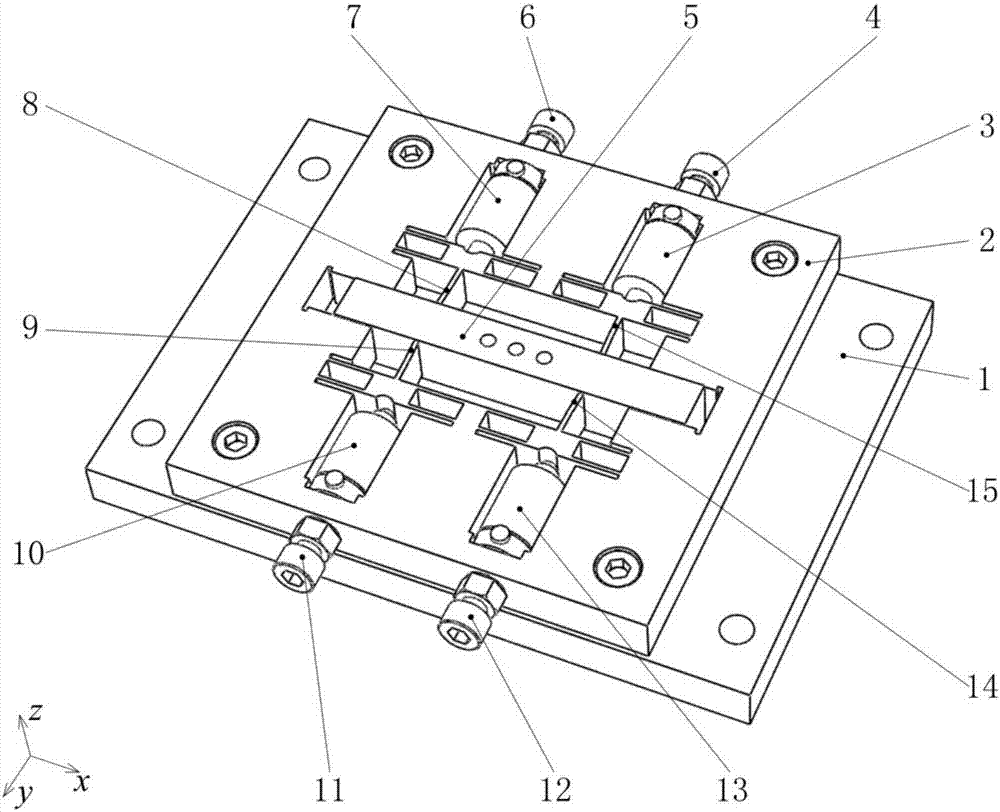

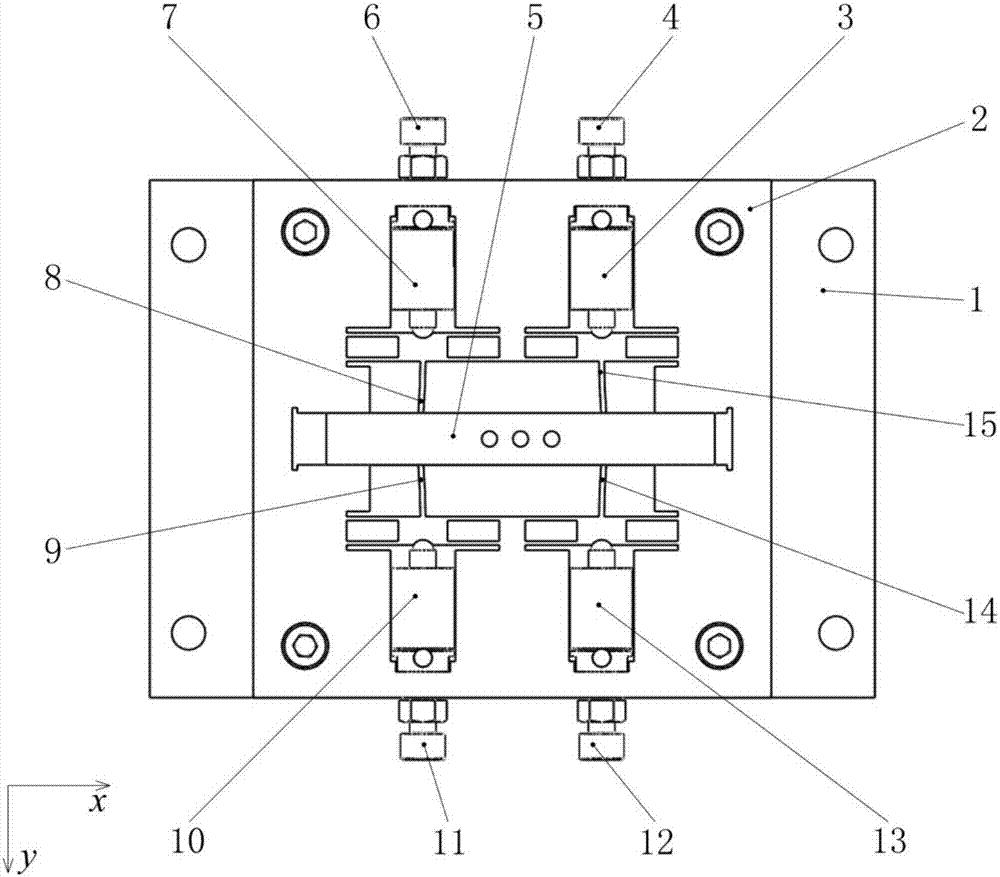

[0037] Specific implementation mode one: refer to Figure 1 to Figure 3 Describe this embodiment in detail. A large-load, high-precision, and cross-scale piezoelectric linear motor based on compliant foot drive described in this embodiment includes a base 1, a stator 2, a forward drive component, and a reverse drive component. and mover 5,

[0038] The structures of the forward drive part and the reverse drive part are the same, and both the forward drive part and the reverse drive part have a symmetrical structure with the mover 5 as the central axis,

[0039] The forward drive components include the first forward drive piezoelectric stack 3, the first forward drive piezoelectric stack pretension bolt 4, the second forward drive piezoelectric stack pretension bolt 12, the second forward drive pressure Electric stack 13, second forward compliant foot 14 and first forward compliant foot 15,

[0040] The reverse drive components include the first reverse drive piezoelectric st...

specific Embodiment approach 2

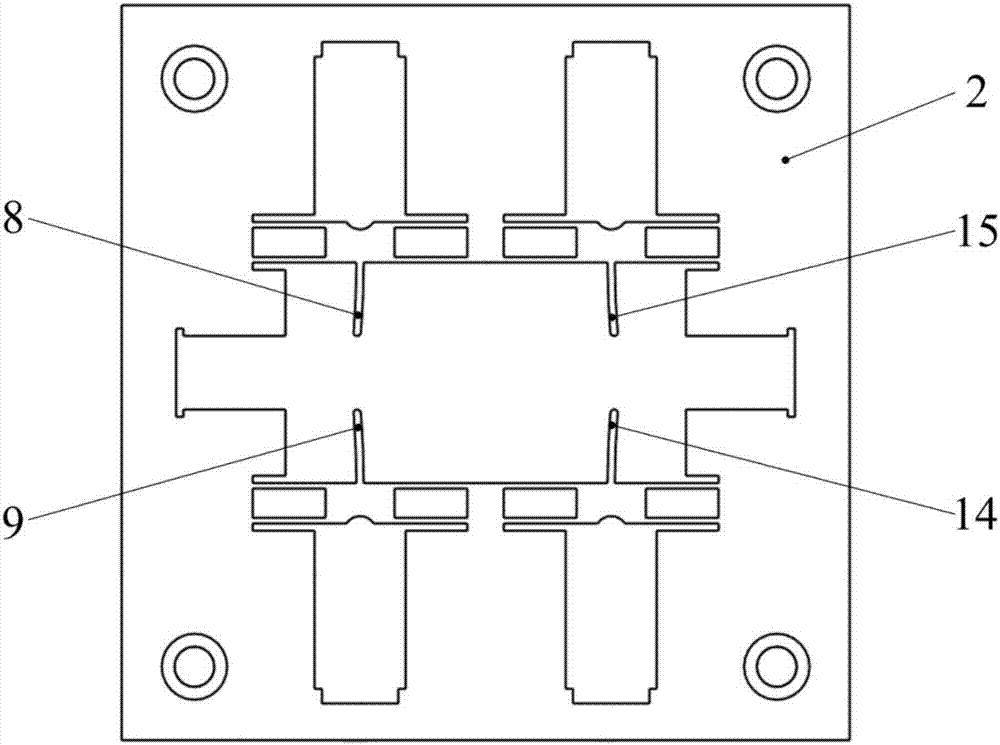

[0052] Specific embodiment 2: This embodiment is a further description of the large-load, high-precision, and cross-scale piezoelectric linear motor based on compliant foot drive described in specific embodiment 1. In this embodiment, the second positive direction compliant The foot 14, the first forward compliant foot 15, the first reverse compliant foot 8, the second reverse compliant foot 9 and the stator 2 are integrally processed.

[0053] In this embodiment, the first reverse compliant foot 8 , the second reverse compliant foot 9 , the second forward compliant foot 14 and the first forward compliant foot 15 are integrally processed with the stator 2 to ensure its precision.

specific Embodiment approach 3

[0054] Specific embodiment three: This embodiment is a further description of a large-load, high-precision, cross-scale piezoelectric linear motor based on compliant foot drive described in specific embodiment one. In this embodiment, it is used to install the mover The guide rail of 5 and stator 2 are processed integrally.

[0055] In this embodiment, the guide rail for installing the mover 5 is integrally processed with the stator 2 to ensure installation accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com