Supercooling plate heat exchanger

A plate heat exchanger and subcooling technology, applied in the direction of heat exchanger type, indirect heat exchanger, fixed plate conduit assembly, etc., can solve the problems of insufficient heat exchange and low degree of fluid turbulence, and improve heat exchange. Efficiency, increasing turbulence, increasing subcooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

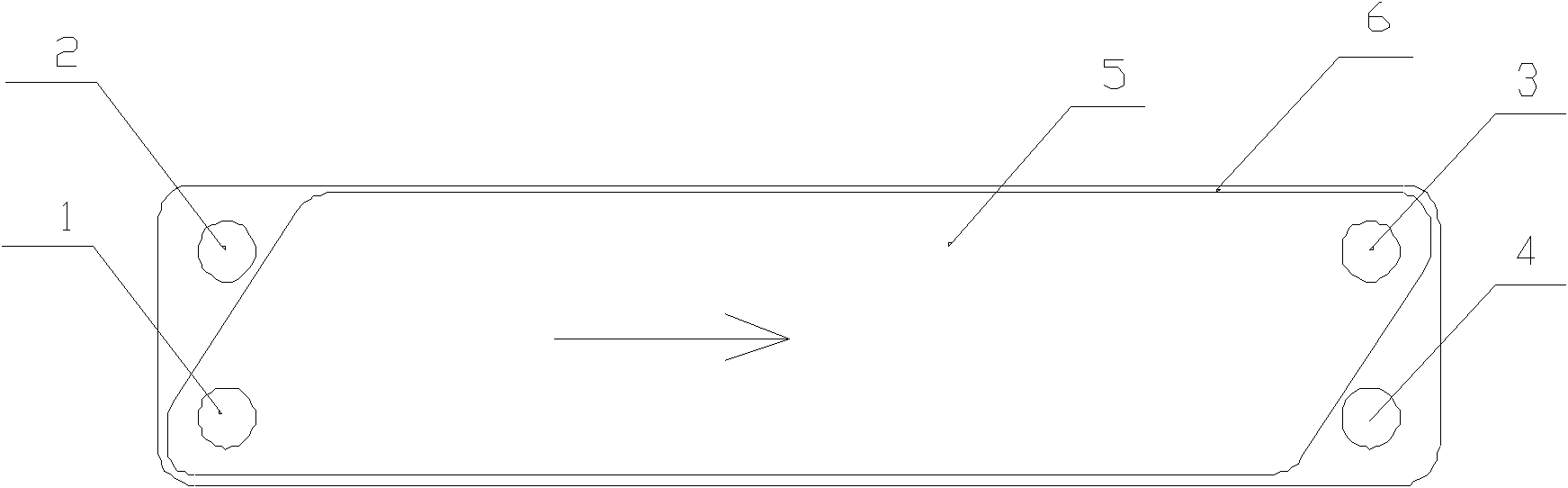

[0019] Such as figure 1 As shown, the direction of the arrow is the macroscopic flow direction of the fluid, the shown dotted line is the concave rib 11, and the shown solid line is the protruding rib 10, as figure 1 As shown, in the supercooled plate heat exchanger of the present invention, the two ends of the main body of the heat exchanger are provided with the cold flow side outlet 2 and the cold flow side inlet 4, and also include heat exchange with the hot flow side outlet 3 and the hot flow side inlet 1 respectively arranged at both ends. Area 5, a sealing member 6 is provided on the side of the heat exchange area 5. Therefore, the sealing member 6 allows the hot fluid to enter from the hot flow side inlet 1, pass through the heat exchange area 5, and flow out from the hot flow side outlet 3. The sealing member 6 prevents the hot fluid from flowing to the cold side. Flow side outlet 2 or cold flow side inlet 4;

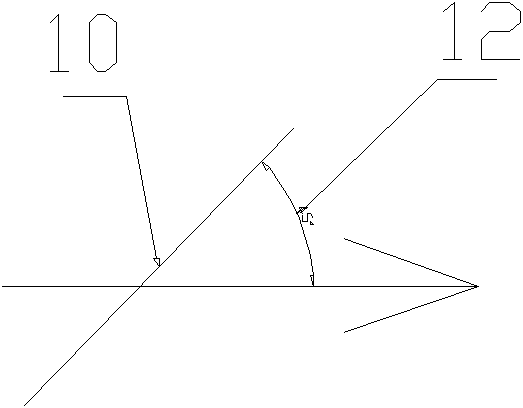

[0020] Such as figure 2 As shown, the figure is a trad...

Embodiment 2

[0027] Such as Figure 5 As shown, the heat exchange area 5 includes a diffuser area 7, a main heat exchange area 8, and a collection area 9 in sequence between the heat flow side outlet 3 and the heat flow side inlet 1, and the main heat exchange area 8 includes three sections. , the first section 81 is provided with protruding ribs 101 and concave ribs 111 that are symmetrically placed at an angle of 50 degrees to the macroscopic flow direction. The first section 81 is the beginning section of heat exchange. The side inlet 1 flows into the diffuse flow area 7, and begins to cool down in this flow section. The angle between the direction of the rib 101 of the plate and the direction of the macroscopic flow is required to be larger, which is 50 degrees;

[0028] The second section 82 is provided with ribs 2 102 and ribs 2 112 that are placed symmetrically at an angle of 10 degrees to the macroscopic flow direction. The heat exchange fluid (referring to the hot side) in this se...

Embodiment 3

[0032] Such as Figure 6 As shown, the heat exchange area 5 includes a diffuser area 7, a main heat exchange area 8, and a collection area 9 in sequence between the heat flow side outlet 3 and the heat flow side inlet 1, and the main heat exchange area 8 includes three sections. , the first section 81 is equipped with protruding ribs 101 and concave ribs 111 that are symmetrically placed at an angle of 80 degrees to the macroscopic flow direction. The first section 81 is the beginning section of heat exchange. The side inlet 1 flows into the diffuse flow area 7, and starts to cool down in this flow section. The angle between the direction of the rib 101 of the plate and the direction of the macroscopic flow is required to be larger, which is 80 degrees;

[0033] The second section 82 is provided with ribs 2 102 and ribs 2 112 that are placed symmetrically at an angle of 40 degrees to the macroscopic flow direction. The heat exchange fluid (referring to the hot side) in this se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com