Countercurrent shaft-drawer type drying machine with movable drawer for drying agglomerations with low mechanical strength

A technology of mechanical strength and countercurrent well, which is applied in the direction of drying solid materials, dryers, heating to dry solid materials, etc., can solve the problems of difficult heat loss, fast wear, and difficult to achieve, and achieve the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

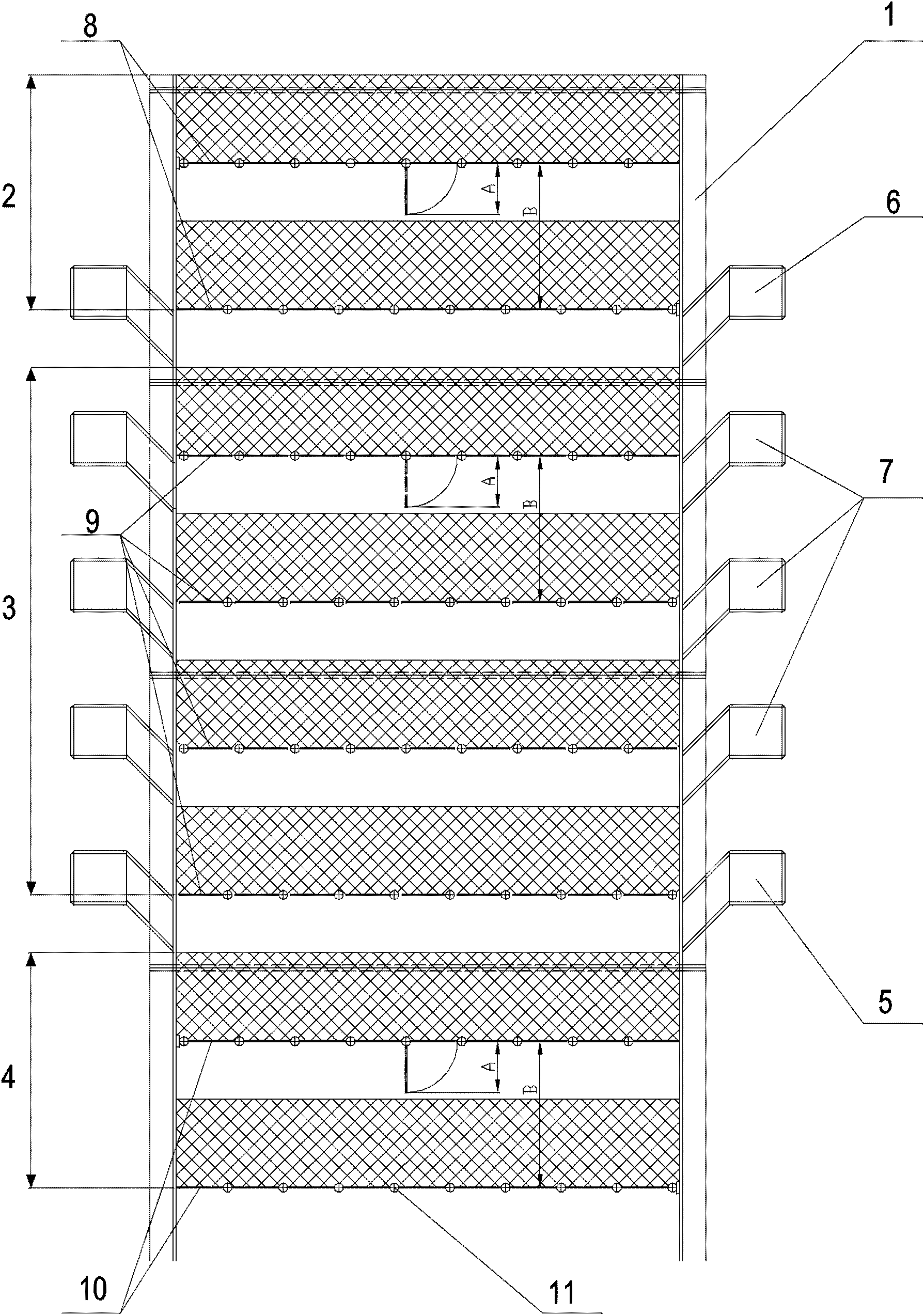

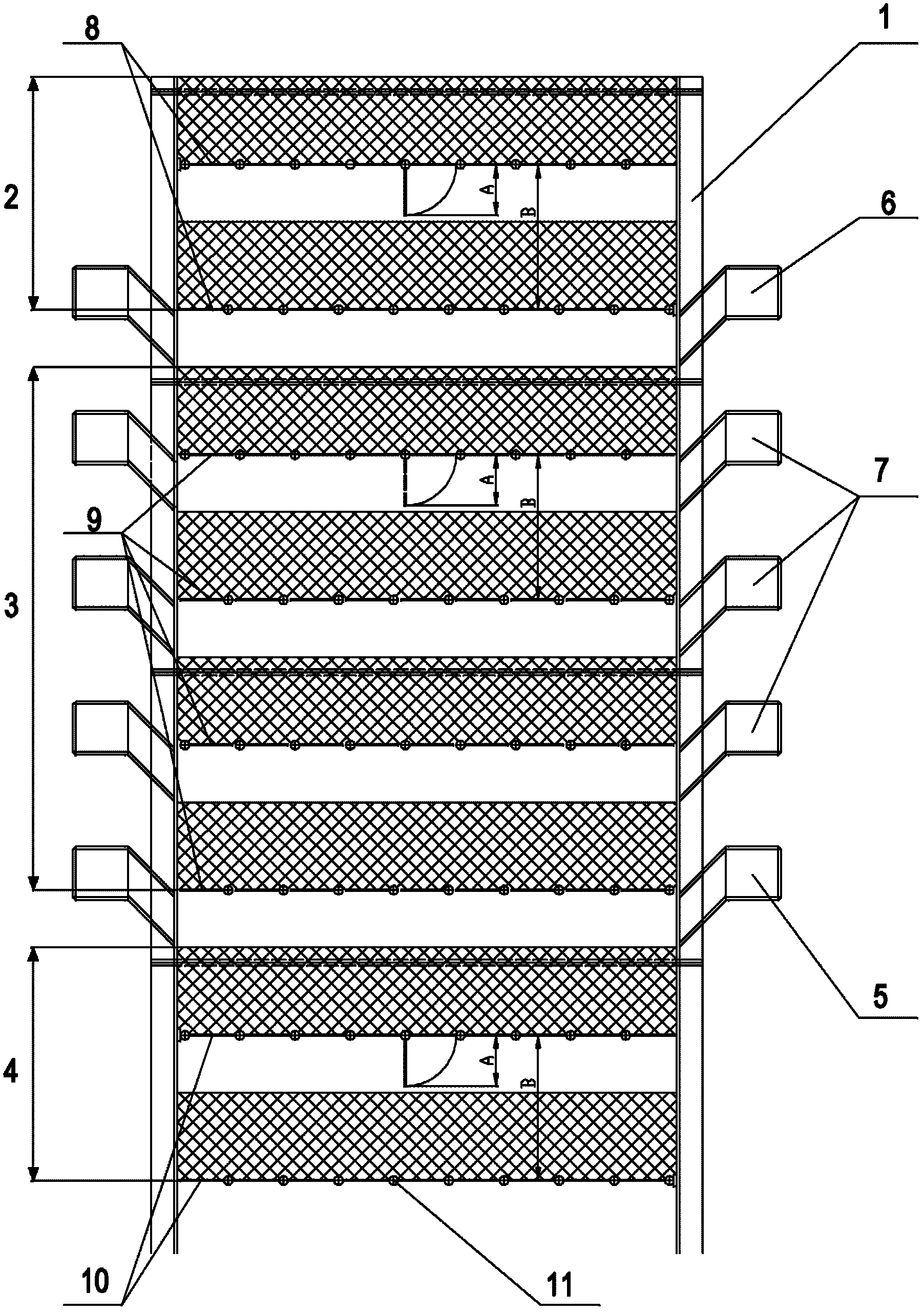

[0025] Countercurrent shaft-drawer dryer with moving drawer for drying agglomerates of low mechanical strength according to the invention is shown as in figure 1 An example of a specific embodiment of the invention in, figure 1 A longitudinal section of the dryer is shown schematically.

[0026] The countercurrent shaft-drawer dryer with moving drawer for drying agglomerates of low mechanical strength according to the invention is constructed as a vertical, preferably square, shaft 1 . The inner space of the shaft 1 is divided into 3 regions. The top feed zone 2 comprises two layers for the granular objects to be dried. The middle drying zone 3 consists of four layers and the bottom discharge zone 4 also consists of two particle layers. Between the bottom discharge zone 4 (surface of the granules on the uppermost layer of zone 4) and the drying zone 3 (lowest layer of zone 3) there is a drying gas inlet stub or inlet header 5. An outlet stub or outlet header 6 for humid ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com