Core fixing cooling radiating system for rotating shaft

A technology for cooling rotating and cooling systems, applied in the cooling field of mechanical parts, which can solve the problems of deformation damage, burnout, and high frequency of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

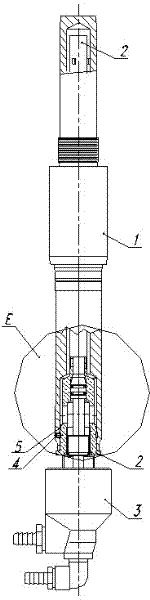

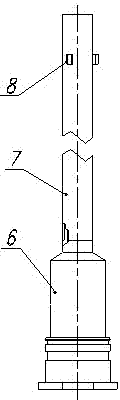

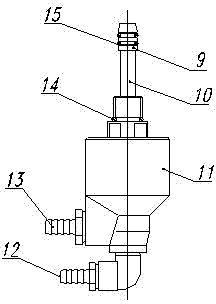

[0011] As shown in the figure, the heat dissipation system for fixed core cooling rotating shaft includes rotating shaft 1, cooling pipe assembly 2, cooling joint assembly 3, inner ball end fastening screw 4 and O-ring 5, wherein cooling pipe assembly 2 includes cooling pipe method Lan 6, cooling pipe 7 and shaft spacer 8; cooling joint assembly 3 includes diverter pipe flange 9, copper pipe 10, elbow joint diverter 11, water inlet pipe joint 12, water outlet pipe joint 13, large sealing ring 14 and The small sealing ring 15; the rotating shaft 1 is set on the outside of the cooling tube assembly 2, and is axially fixed by the inner ball end screw 4; the cooling joint assembly 3 is set on the inside of the cooling tube assembly 2; The inner thread is connected, one end of the inner ball end screw 4 is in the rotating shaft 1, the other end of the inner ball end screw 4 is in the annular groove at the lower part of the cooling pipe assembly 2, and the O-ring 5 is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com