Design method of shaft sleeve used for rocker arm of coal mining machine

A design method and shearer technology, applied in the direction of mechanical equipment, engine lubrication, bearing components, etc., can solve problems such as difficult maintenance work, affecting enterprise benefits, and affecting coal mining speed, so as to reduce maintenance frequency and improve operation speed and workload, the effect of prolonging the lubrication time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

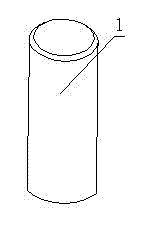

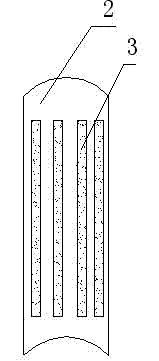

[0020] In order to increase the lubrication time between the bushing and the drive shaft, reduce the maintenance frequency, and increase the working speed and workload, this embodiment provides a method such as figure 1 , 2 The shaft sleeve used for the rocker arm of the coal shearer shown in .

[0021] like figure 2 As shown, the groove 3 extends along the axial direction of the inner wall 2 .

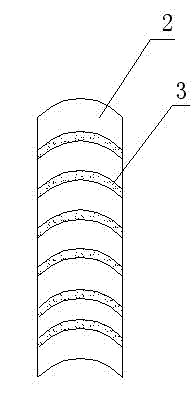

[0022] like image 3 As shown, the groove 3 can also extend along the circumference of the inner wall 2 .

[0023] In order to ensure uniform lubrication, the grooves 3 are uniformly arranged on the inner wall 2 .

[0024] Furthermore, in order to improve maintenance efficiency, such as Figure 4 As shown, a filling hole 4 for filling lubricant can be opened on the outer wall 1 of the sleeve, which communicates with the groove 3 on the inner wall 2, and a plurality of filling holes can be evenly arranged along the groove 3, so that, Lubricant filling can be achieved without dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com