Split cylinder independent closed loop control method for homogeneous charge compression ignition (HCCI) combustion on basis of knock sensor

A knock sensor and closed-loop control technology, which is applied in fuel injection control, electrical control, engine control, etc., can solve the problems of poor reliability, poor industrialization feasibility, and high cost of cylinder pressure sensors, and achieve stable HCCI combustion and industrialization. High performance and simple control strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

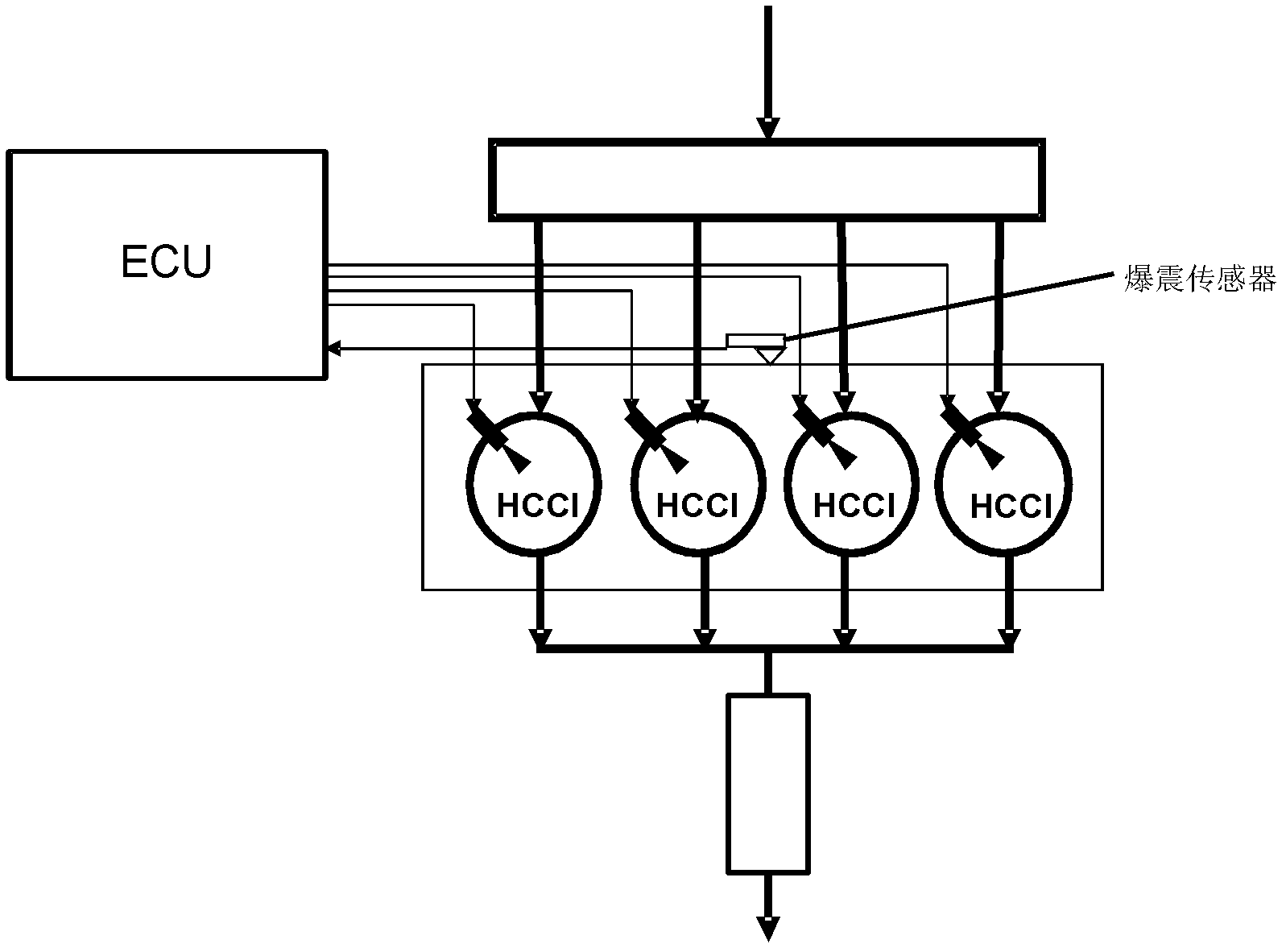

[0023] The present invention provides a method for independent closed-loop control of HCCI combustion cylinders based on a knock sensor. The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0024] The method of the present invention comprises the following steps, and its flow chart is as follows Figure 6 Shown:

[0025] Step 1, the knock sensor detects the vibration signal when the engine is burning.

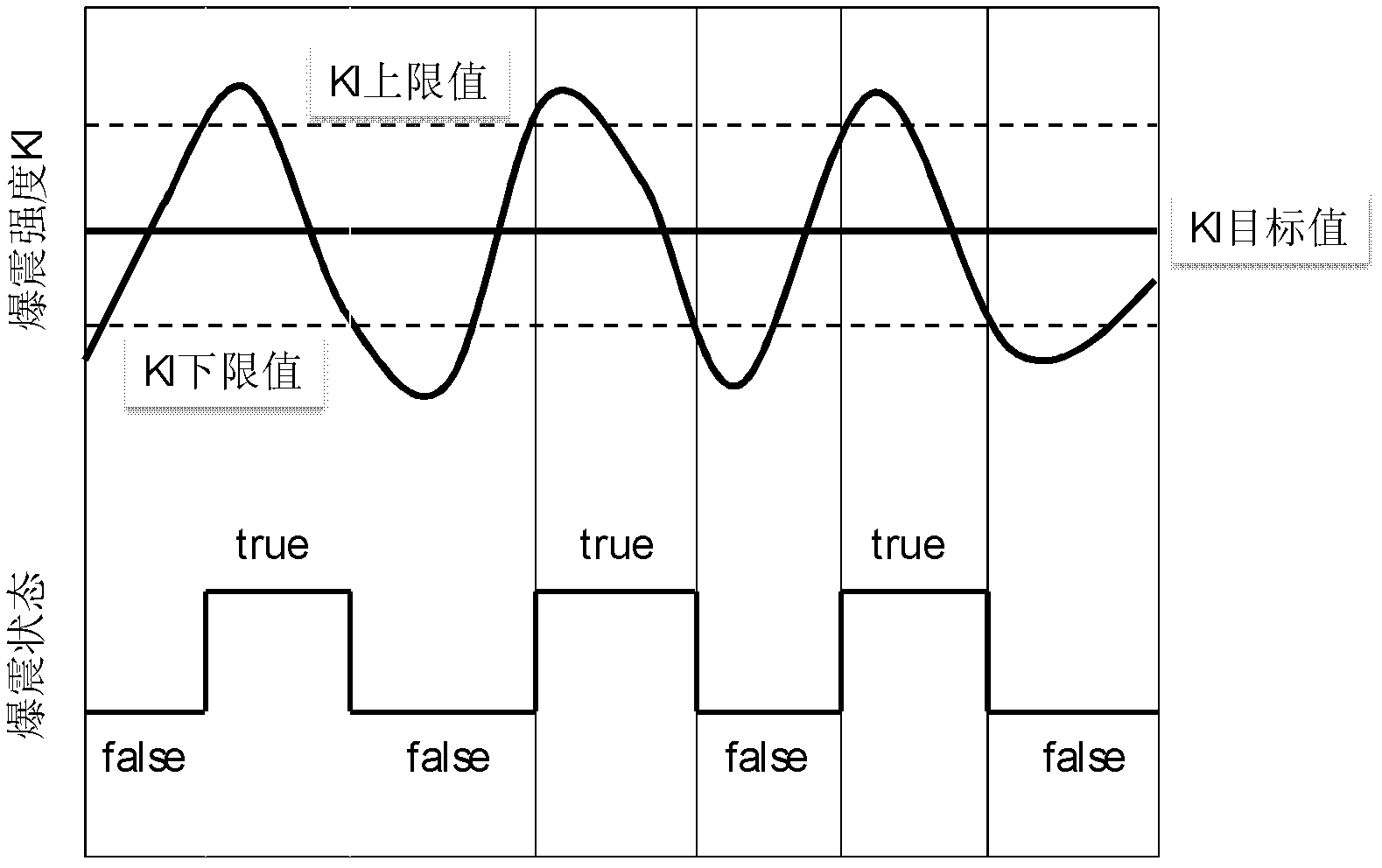

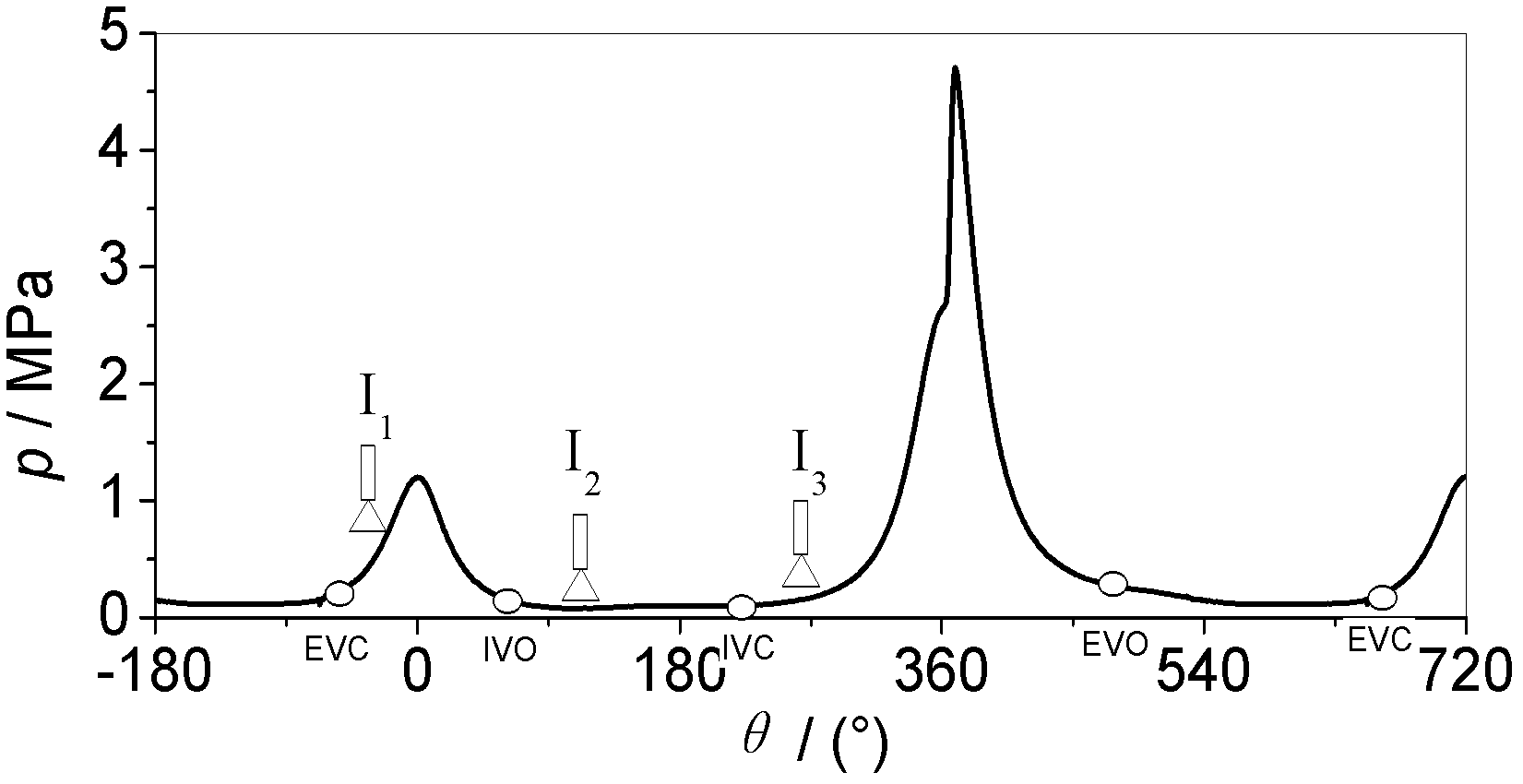

[0026] In step 2, the ECU integrates the vibration signal of the knock sensor according to the ignition sequence of the engine to obtain the knock intensity (KI_i) value of each cylinder. When HCCI combustion knocks, the knock signal sensor generates a strong sawtooth wave in the voltage signal, such as Figure 5 ;Integrate the absolute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com